HCCI engine is a hybrid of spark

ignition (SI) and compression ignition (IC) diesel engines

with a goal to theoretically harness advantages of both in a

single setting. Similar to SI engines, a homogeneous

fuel/air mixture is inducted into the engine. During the

compression stroke the temperature of the mixture increases

and reaches the point of autoignition; i.e. the combustion

is initiated without the help of any ignition system.

advantages of both in a

single setting. Similar to SI engines, a homogeneous

fuel/air mixture is inducted into the engine. During the

compression stroke the temperature of the mixture increases

and reaches the point of autoignition; i.e. the combustion

is initiated without the help of any ignition system.

The early studies of this

phenomenon were conducted on two-stroke engines with the

goal to reduce the hydrocarbon (HC) emission at part load

condition. The historical development in two-stroke engines

by itself is educational. In the l970s, Eiji Toyoda,

founder of Toyota Motor Co. In Tokyo, experienced the

abnormal run-on behavior with his motorcycles and challenged

his staff engineers to explain it. Masaaki Noguchi and a

team of researchers from Toyota and Nippon Soken Inc.

investigated this unusual effect, and determined that it was

caused not by the assumed hot spots but by an interaction

between fuel chemistry and the temperature and pressure

conditions in the engines’ cylinders. Specifically, the

self-ignited combustion tends “to occur at relatively low

cylinder pressures and temperature (compared to diesel

combustion), presumably by virtue of intermediate reaction

products [active radicals]”. Using partially-transparent

optical engines with quartz observation ports, the

researchers detected that the stable combustion behavior

was characterized by an intense blue glow, which was later

shown to be the fluorescence of active radicals. The group

named the phenomenon Toyota-Soken combustion.

Around the same time, Shigeru

Onishi and his coworkers at Nippon Clean Engine

Research Institute Co. Ltd. showed a small

single-cylinder motor/generator set (called the nice engine)

that ran with no spark. The team called the phenomenon they

observed active thermo-atmosphere combustion. In both these

research projects, the engineers could make their engines

operate sparkless on radical-initiated combustion, but

only at constant speed and load. They had, however,

determined some empirical characteristics of this third type

of burning. The autoignition occurred only at low loads,

when there was a large amount of hot residual gas in the

cylinders. As the temperature rose further during the

compression, the initiating reactions in the fresh chargewere beginning, and the hydrocarbons in the fuel were

breaking down into simpler compounds and activated

radicals.

Similar effects can be achieved

in four stroke engines as well. Like an SI engine the

charge is well mixed which minimizes particulate emissions,

and like a diesel engine it has no throttling losses, which

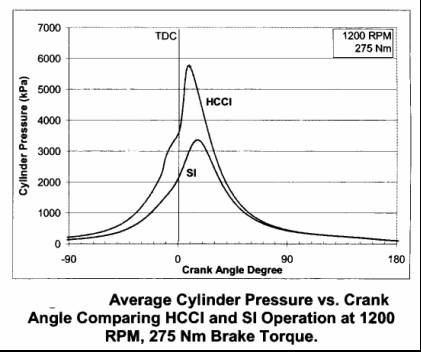

is beneficial for the part load operation. In addition, the HCCI engine can operate at diesel like compression ratios,

leading to comparable efficiencies. The distinction is that,

unlike either SI or CI engine the combustion occurs

simultaneously throughout the cylinder volume rather than

within a flame front. Hence, pressure ris e is very rapid

particularly when an stoichiometric or rich mixture is

used, for example, under high load conditions. See Fig. 1

for examples of SI and HCCI pressure traces. Many

investigators observed knock-like pressure oscillations in

HCCI engines under high load conditions. However, one

feature of the HCCI engine is that auto-ignition can be

achieved with very lean overall mixtures (much leaner than

can be ignited by spark ignition). This by itself, almost

eliminates the requirement of throttling at low engine

loads. It worth indicating that one main reason in

throttling spark ignited engine is to ensure spark ignitable

mixture. It should be obvious that there is no explicit

timing for the HCCI combustion. This is considered as one of

the unresolved and actively researched areas to best

control HCCI combustion in each cylinder.

e is very rapid

particularly when an stoichiometric or rich mixture is

used, for example, under high load conditions. See Fig. 1

for examples of SI and HCCI pressure traces. Many

investigators observed knock-like pressure oscillations in

HCCI engines under high load conditions. However, one

feature of the HCCI engine is that auto-ignition can be

achieved with very lean overall mixtures (much leaner than

can be ignited by spark ignition). This by itself, almost

eliminates the requirement of throttling at low engine

loads. It worth indicating that one main reason in

throttling spark ignited engine is to ensure spark ignitable

mixture. It should be obvious that there is no explicit

timing for the HCCI combustion. This is considered as one of

the unresolved and actively researched areas to best

control HCCI combustion in each cylinder.

It was shown that H, OH, and HO2

radicals play key role in autoignition process. In

general, the concentration of the hydrogen peroxide (H2O2)

increases in time and then begins to decompose (at

temperatures between 1050 to 1100 K) at high rate to

hydroxyl (OH) radicals. This reaction produces a large

number of OH radicals, most of which then react with fuel

molecules to generate water and heat. The increased

temperature brings the system into a very effective chain

branching state. The fundamental chemistry of HCCI

autoignition appears to be identical to that of knock in SI

engines. However, the picture does not favor the notion

that “active radicals” in the residual burned gases

survive both the exhaust and intake processes to play a role

in HCCI autoignition process in the next cycle.

Current research activities cover

areas such as control, startability, emissions of

hydrocarbon and carbon monoxide, power density, and

transition to other modes of operation, that is SI or

diesel. For more information refer to SAE 2001-01-2511 and

other SAE literature.

NOTE:

Course materials are in

preparation (contact us for more details). Consulting

activities are available.