%20&%20NOx%20%20reduction%20Diesel%20Chehroudi.jpg)

-

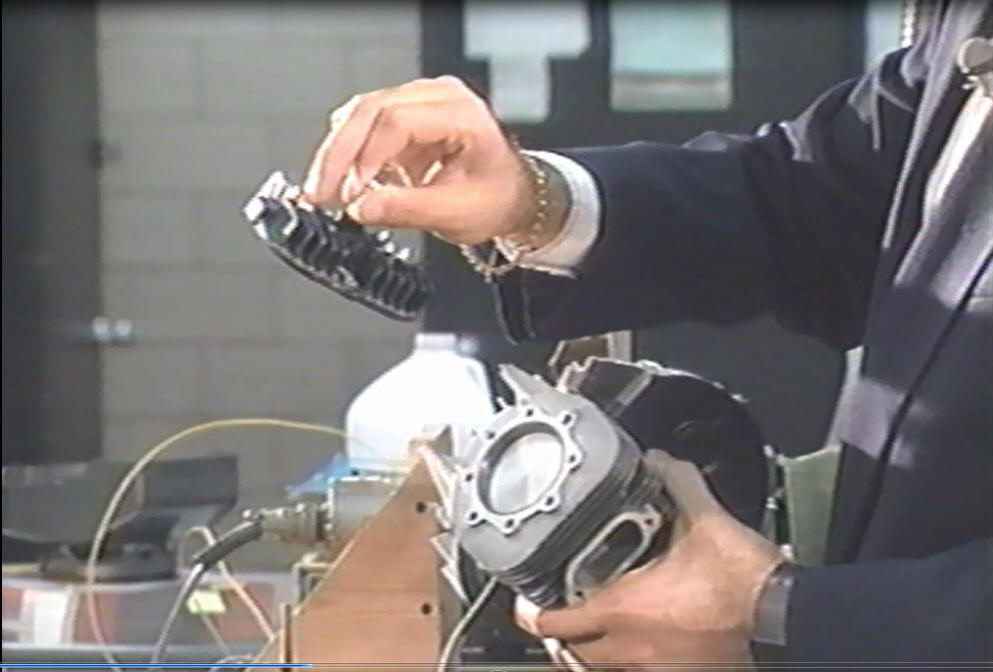

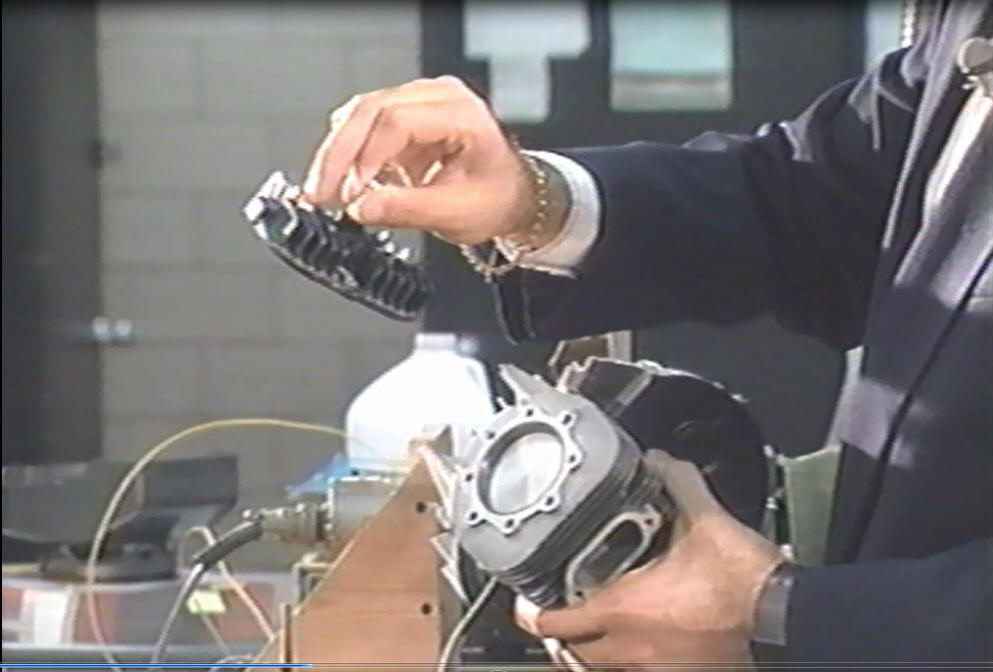

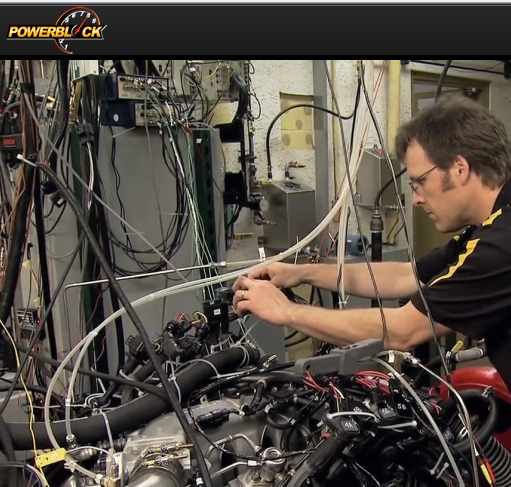

This video

clip (click on the right image to run the video) shows a test setup of a single-cylinder small two

-stroke gasoline-fueled engine on a small dynamometer. The

engine head is equipped with a pressure transducer to provide

traces for combustion signature diagnostics. In this case, a

one-zone model is used to calculate the heat release rate and

mass fraction burned information to understand the combustion

characteristics of this engine.

-

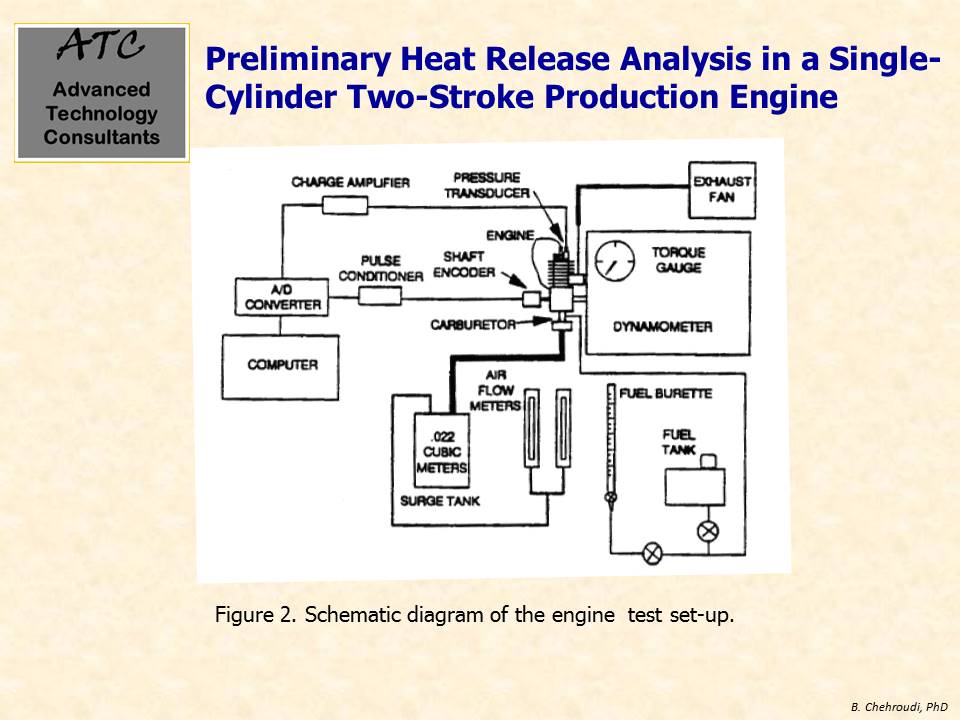

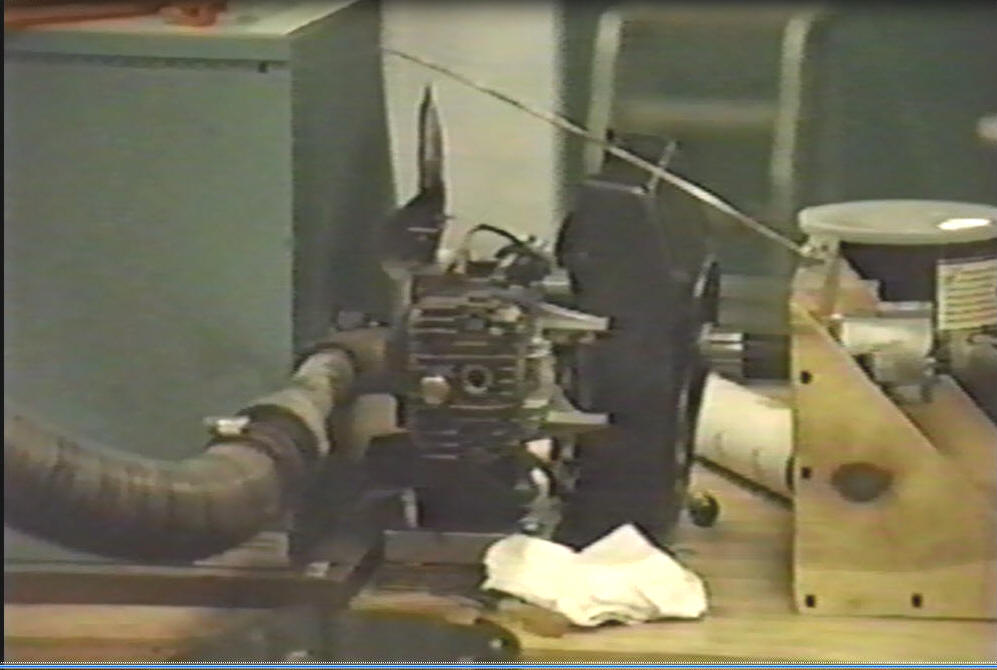

This video clip

(click on the right image to run the video) describes a small engine

test setup showing a dynamometer along with necessary piping

system for the

intake and exhaust as well as measurement systems needed for air

and fuel flows rates into the engine/

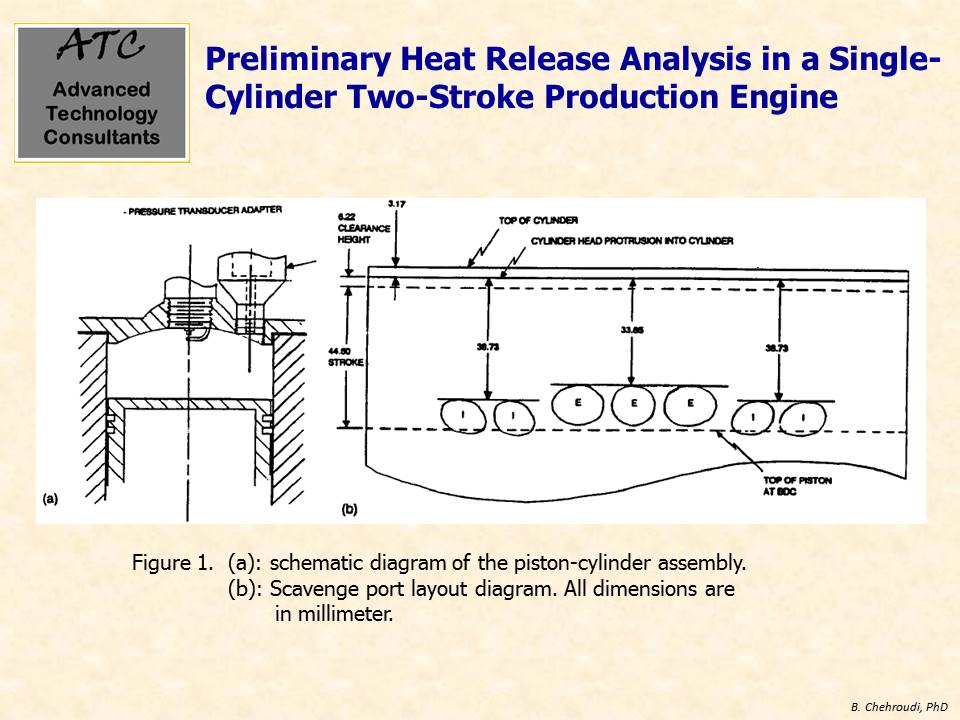

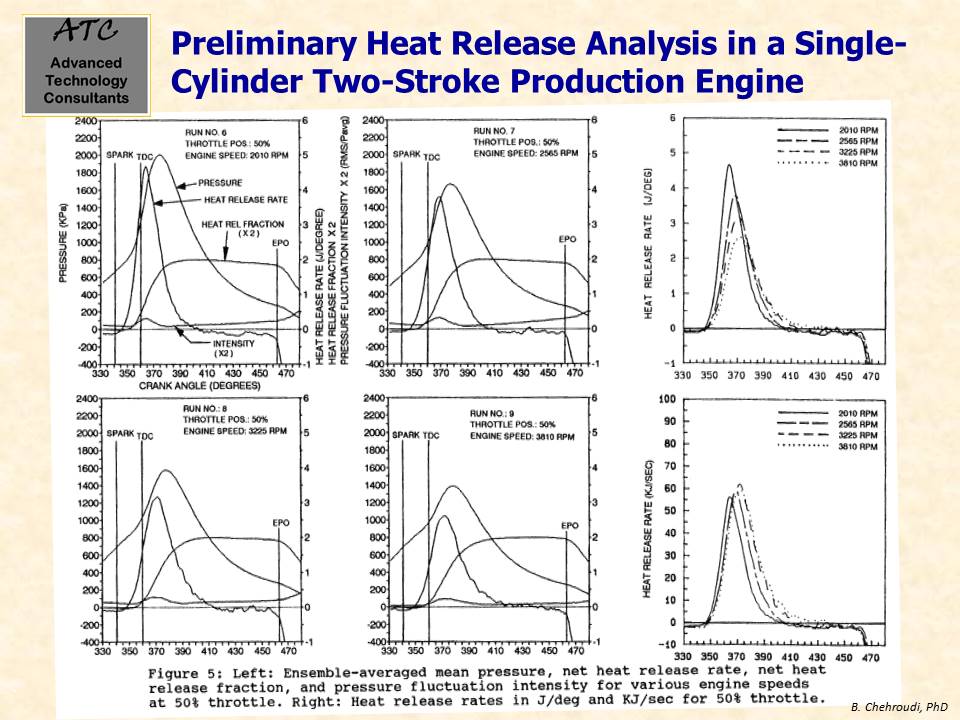

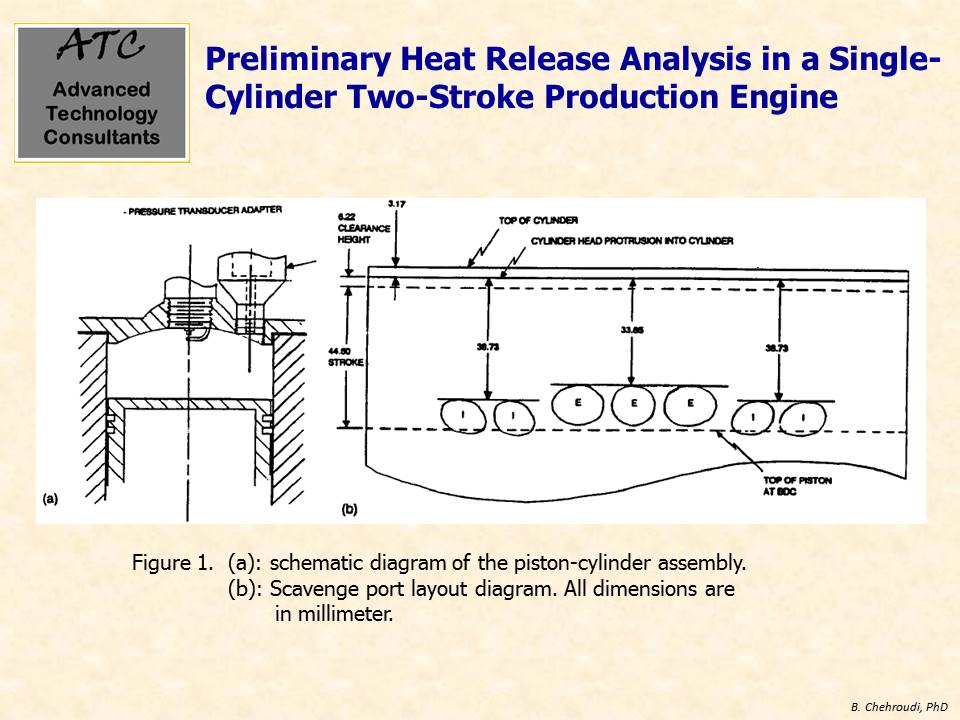

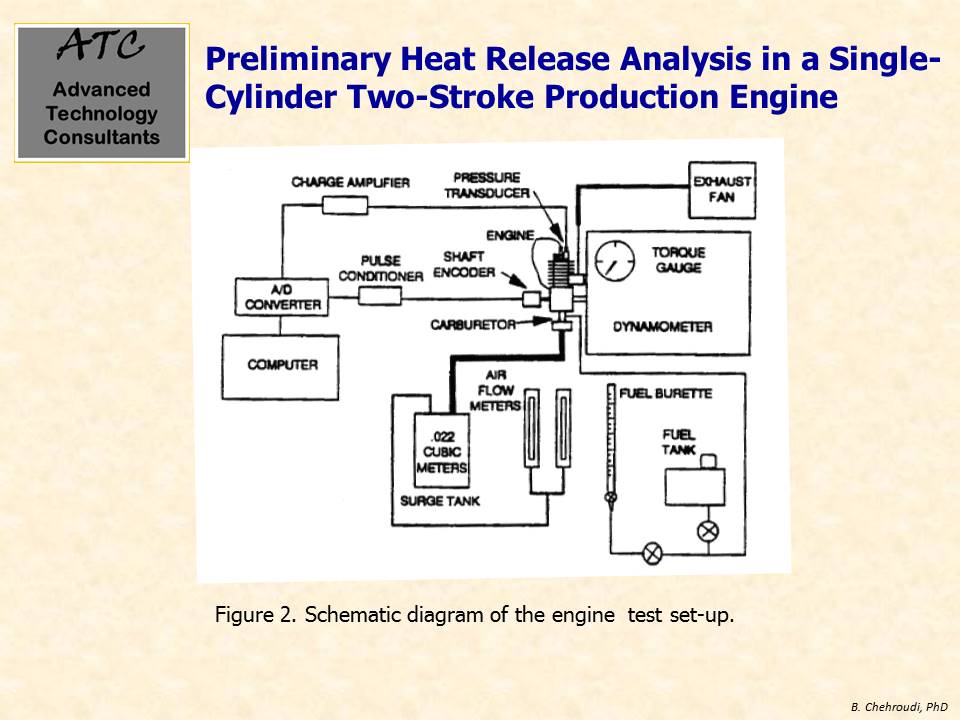

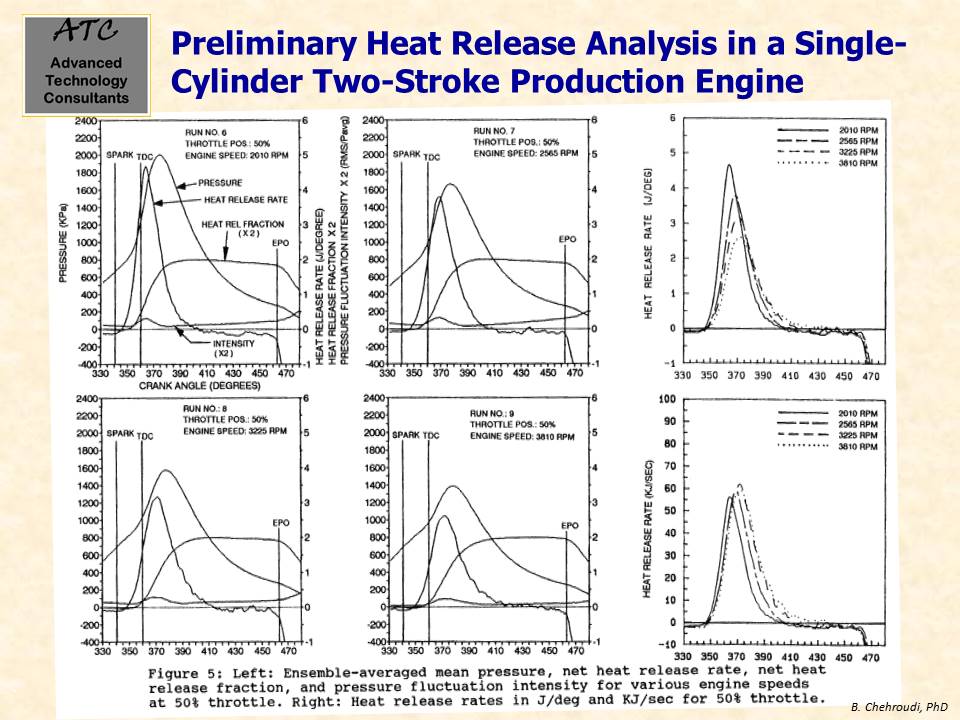

Results have been published in the literature. For

example, see Rohrer, R. and Chehroudi B., 1993.

Preliminary Heat

Release Analysis in a Single-Cylinder Two-Stroke Production

Engine, Society of Automotive Engineers, 1993 Congress and

Exposition, SAE Transaction Paper 930431, March 1-5.

-

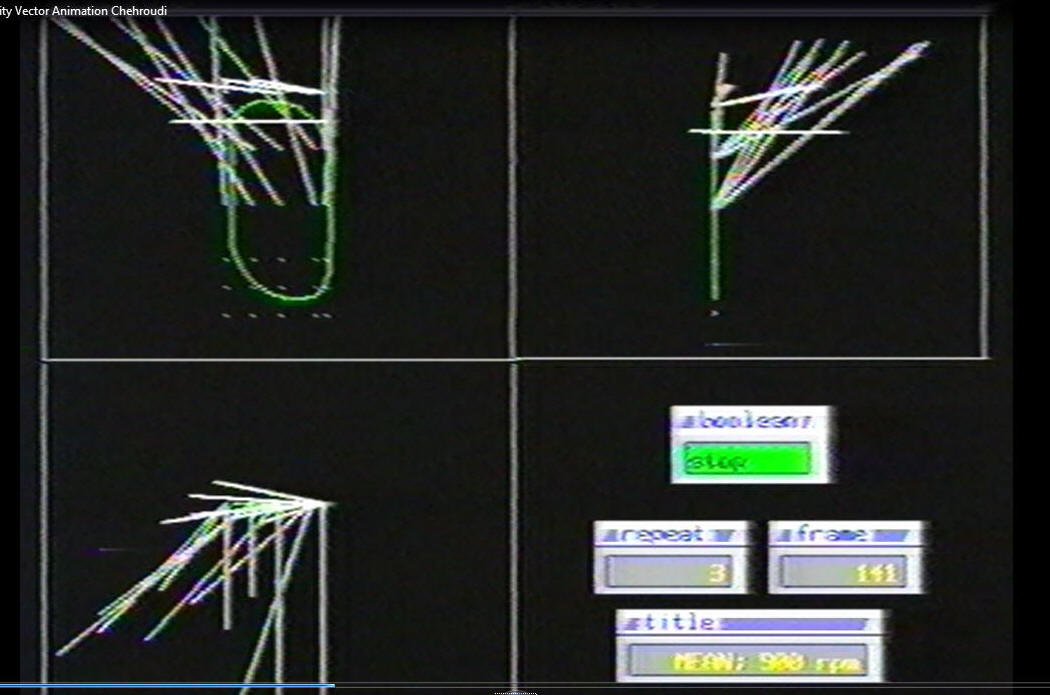

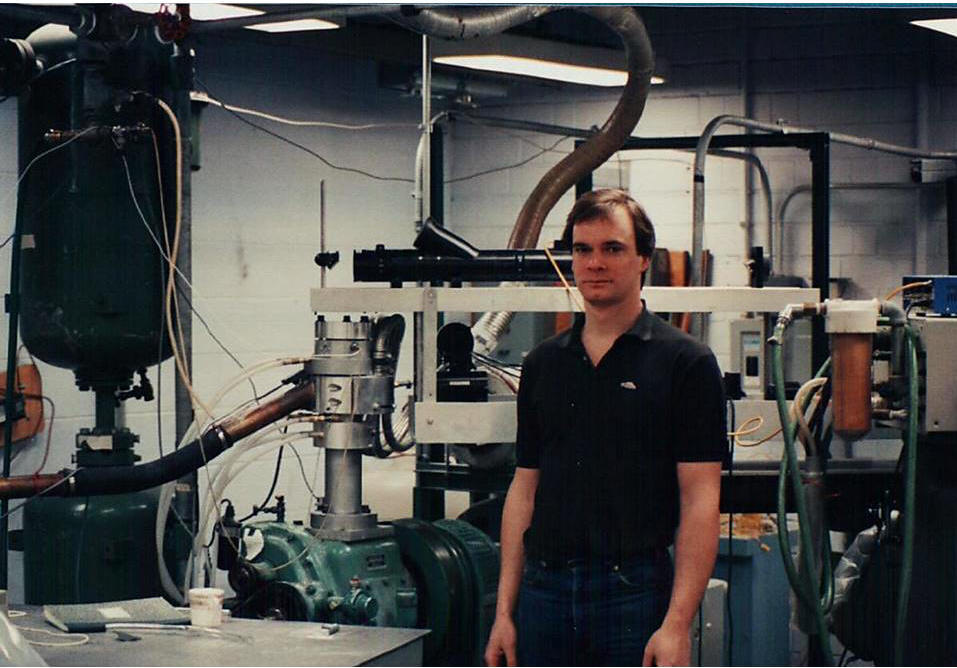

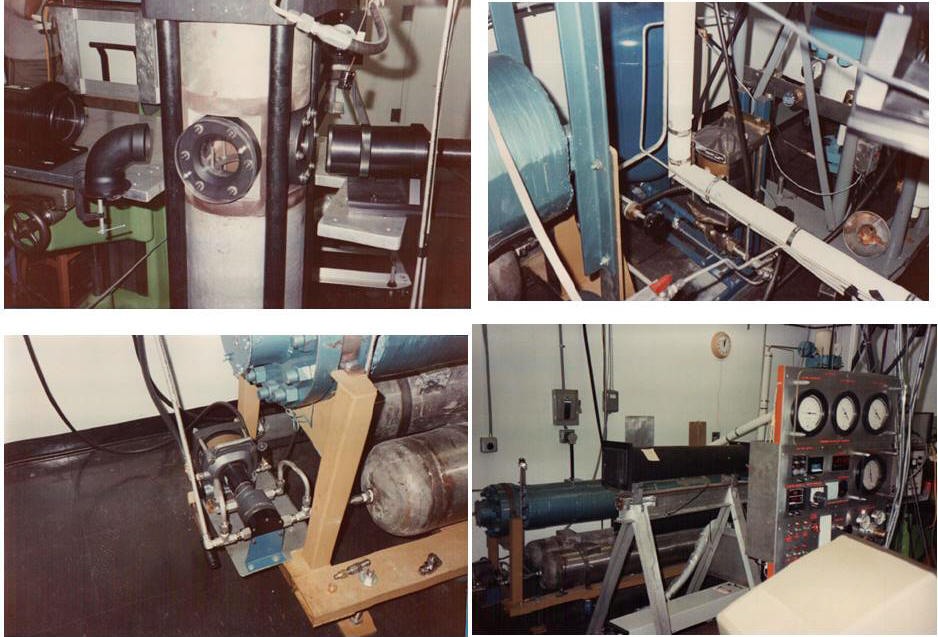

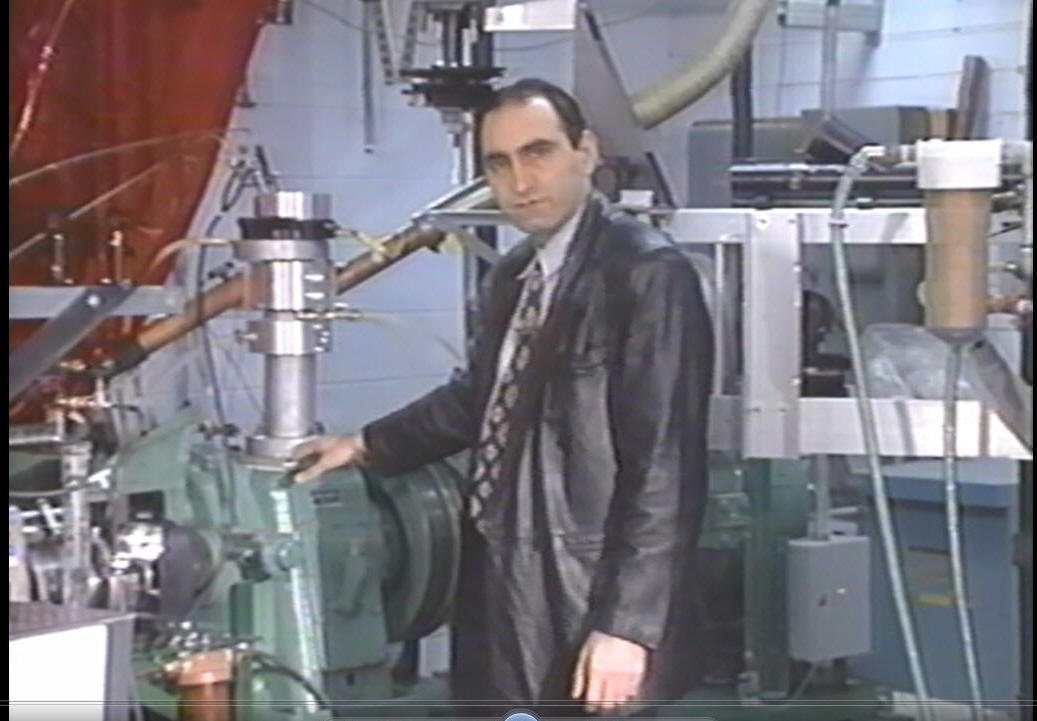

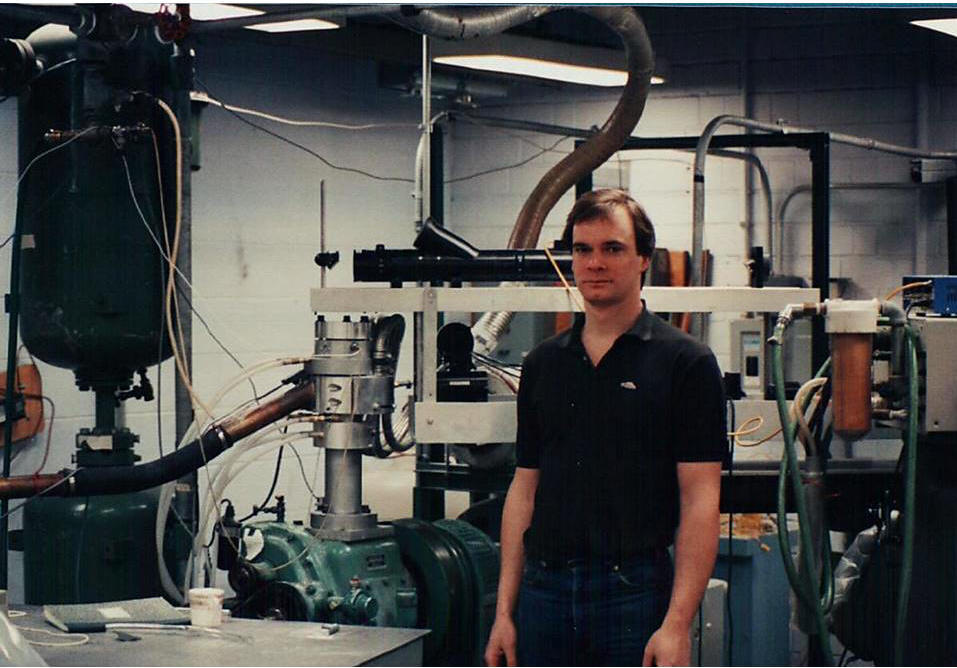

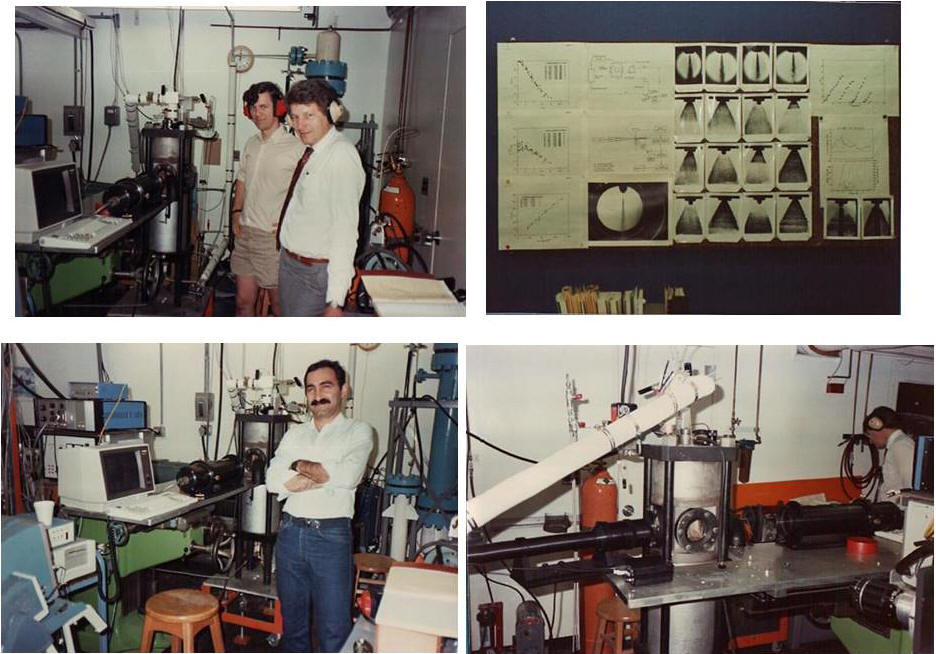

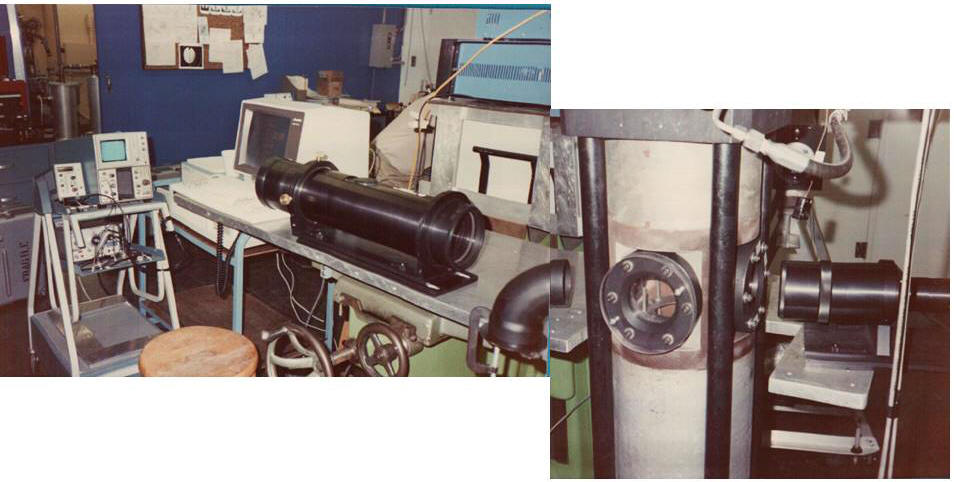

This video

clip (click on the right image to run the video) shows operation of

an engine for intake port flow measurements using Laser Doppler Velocimeter (LDV). The entire transmitting optics are on a

lathe machine base to enable precise XYZ traverse for

easy optical alignment/measurement purposes as well as achieving

convenient rotation of portion

of the transmitting optics along the engine axis for rapid

intake port flow measurements (engine was under two-stroke operation).

The person in the image is

Konstantinos Boulouchos who was a visiting researcher to

the

laboratory (currently a professor at the ETH Zurich,

Switzerland).

Results have been published in the literature. For

example, see Bardsley, M. E. A., Boulouchos, K., Gajdeczko, B.,

Chehroudi, B., and Bracco, F. V., 1989.

Measurements of the

Three Components of the Velocity in the Intake Ports of an I. C.

Engine, Society of Automotive Engineers, 1989 Congress and

Exposition, SAE Transaction Paper 890742, February 27 - March 3.

-

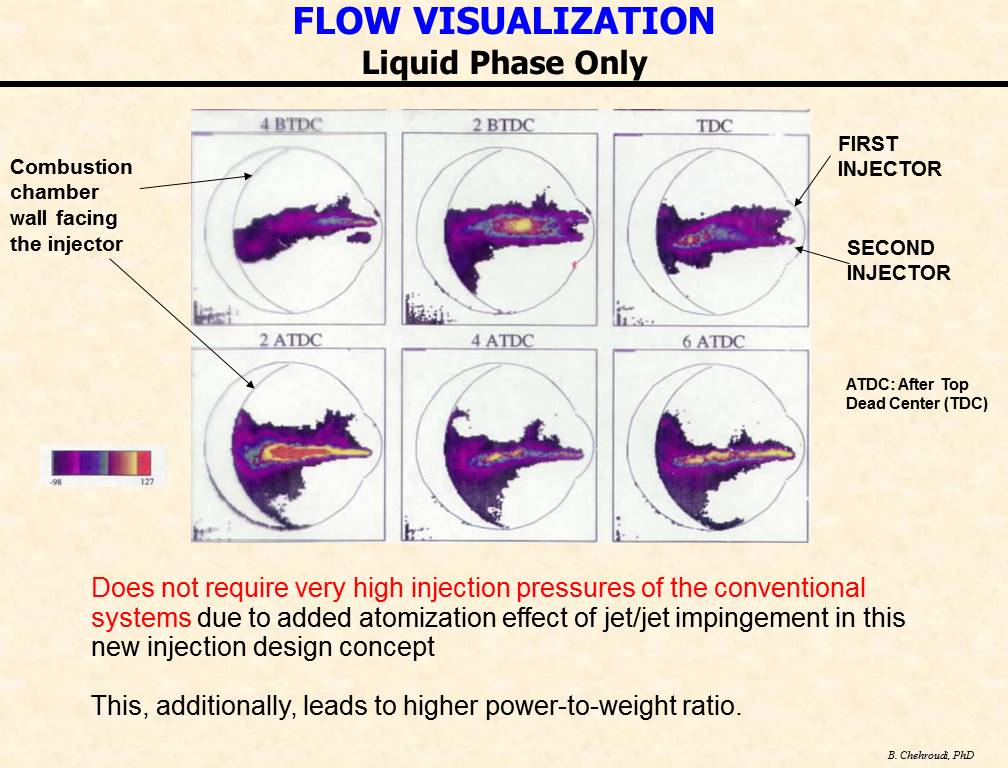

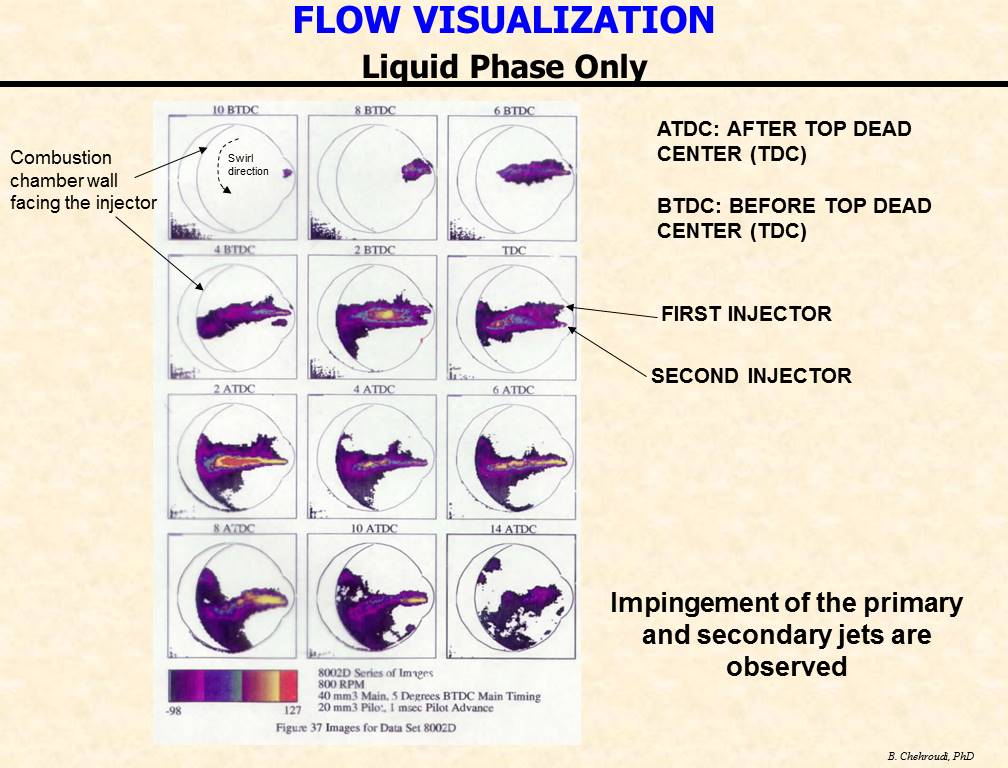

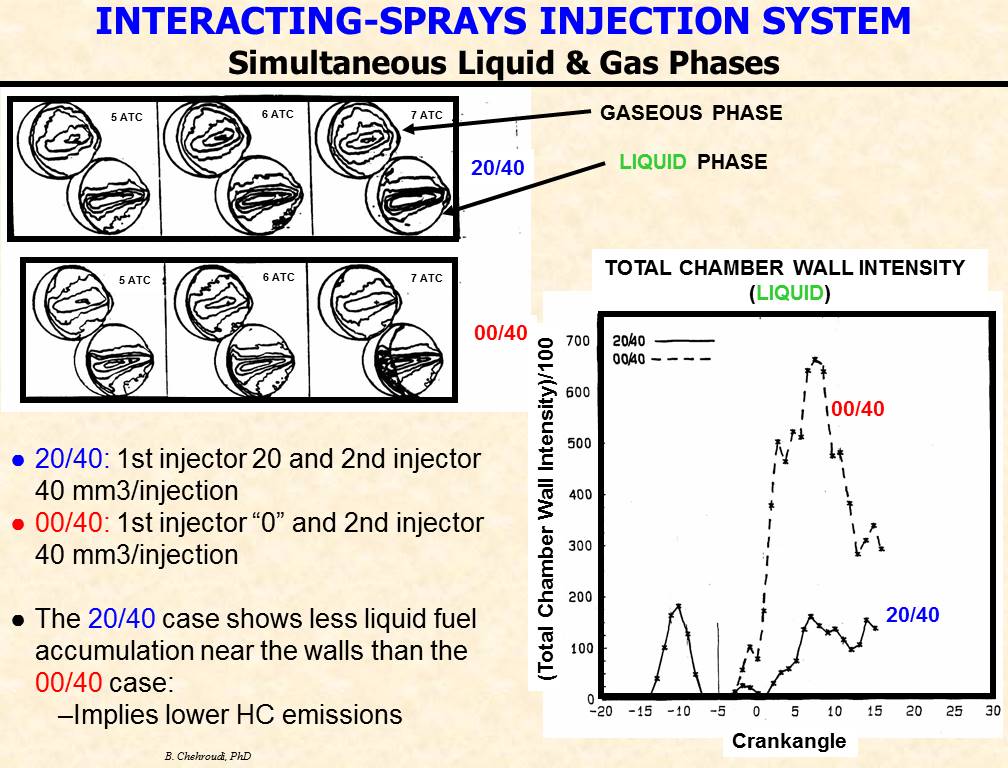

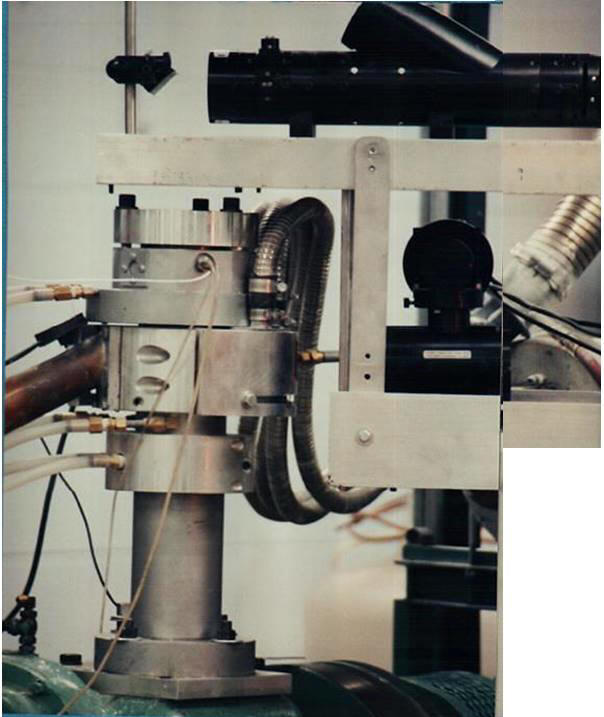

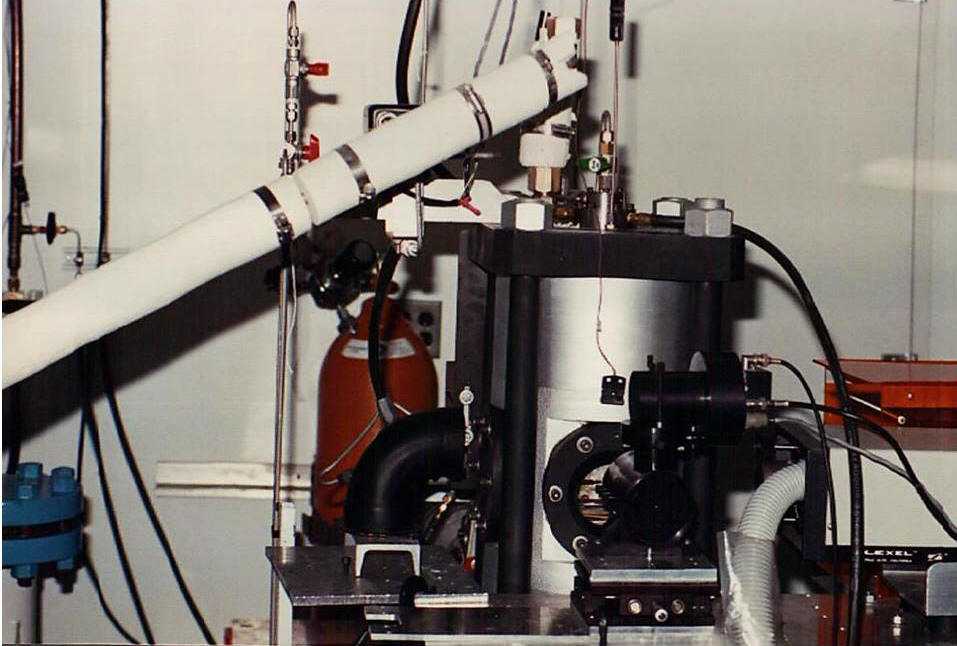

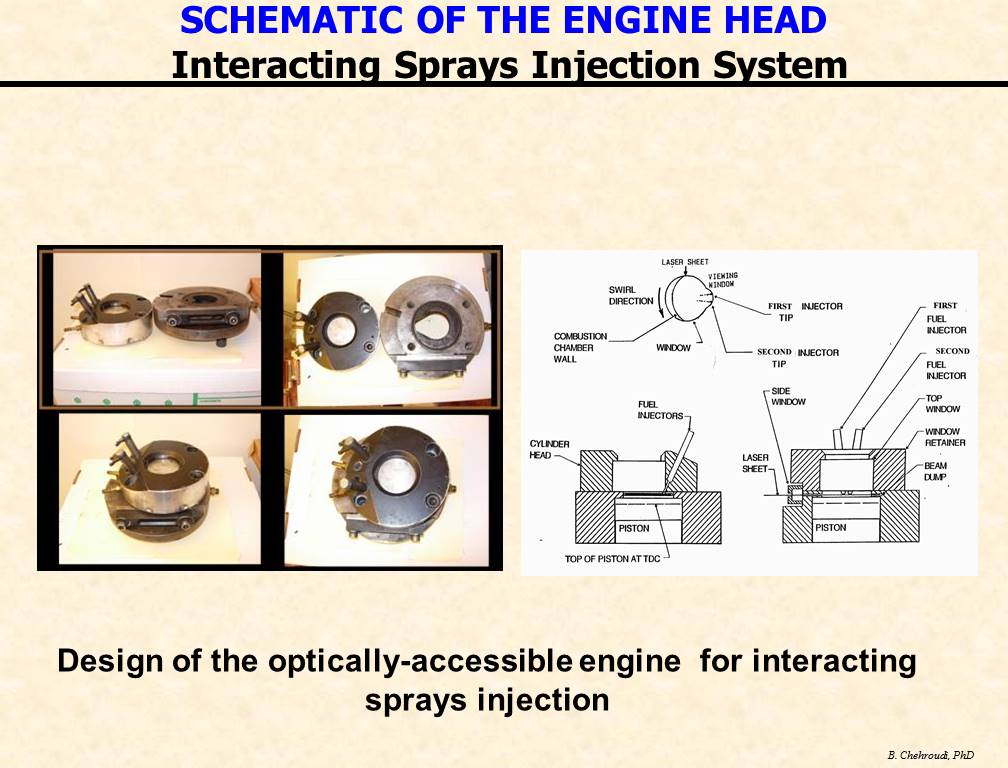

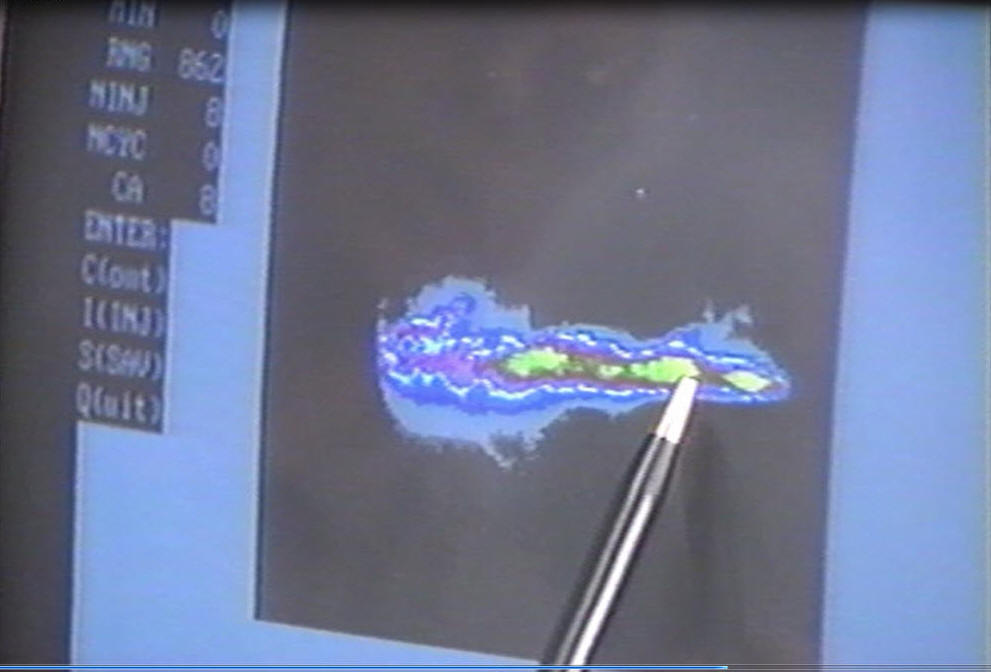

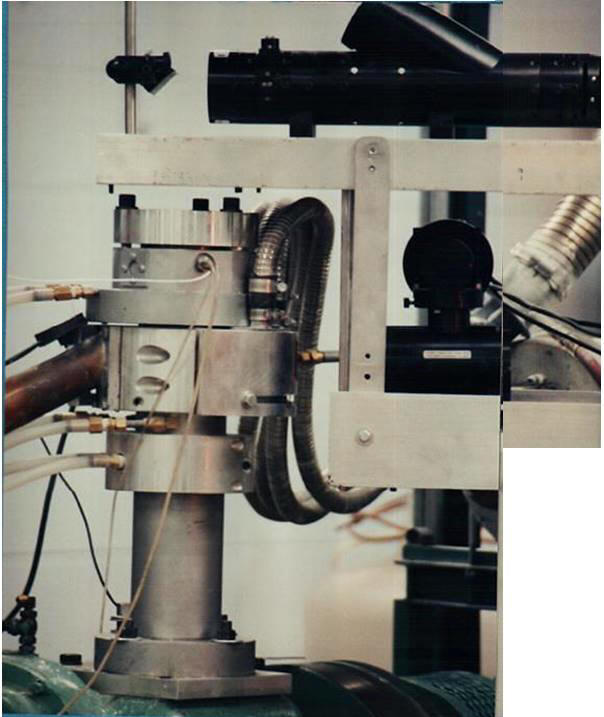

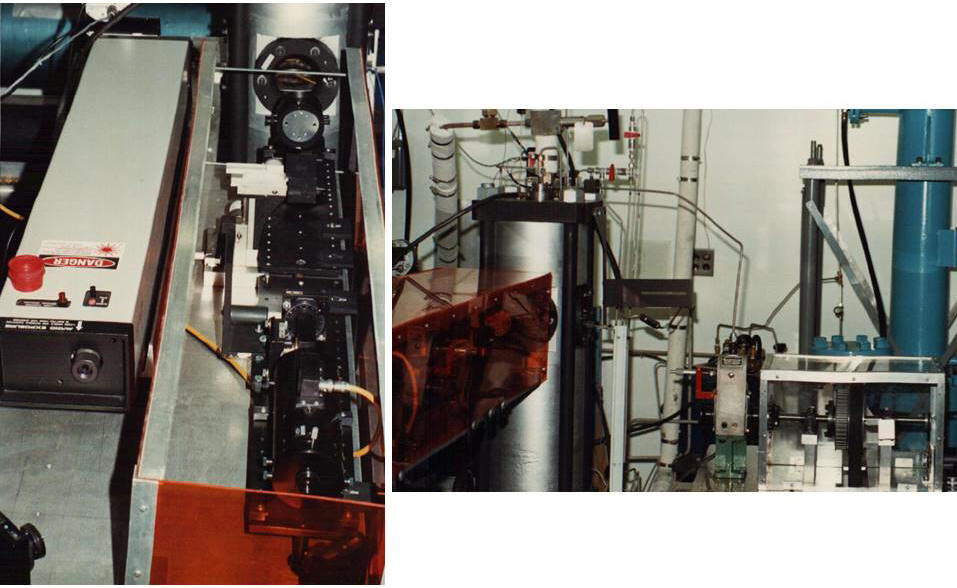

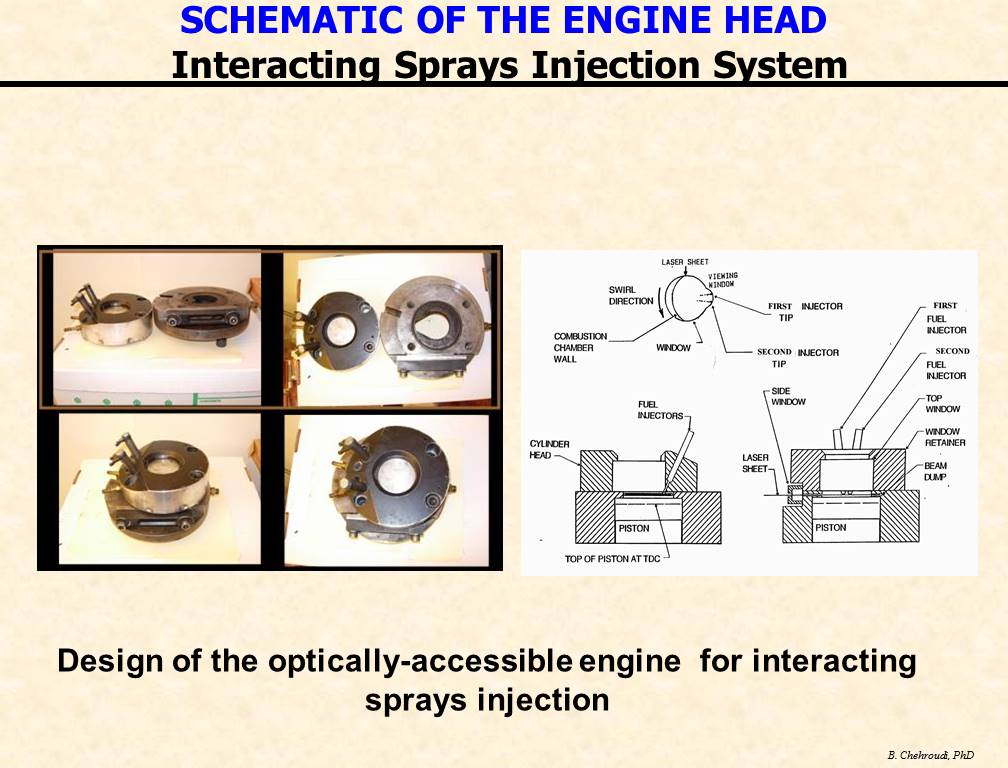

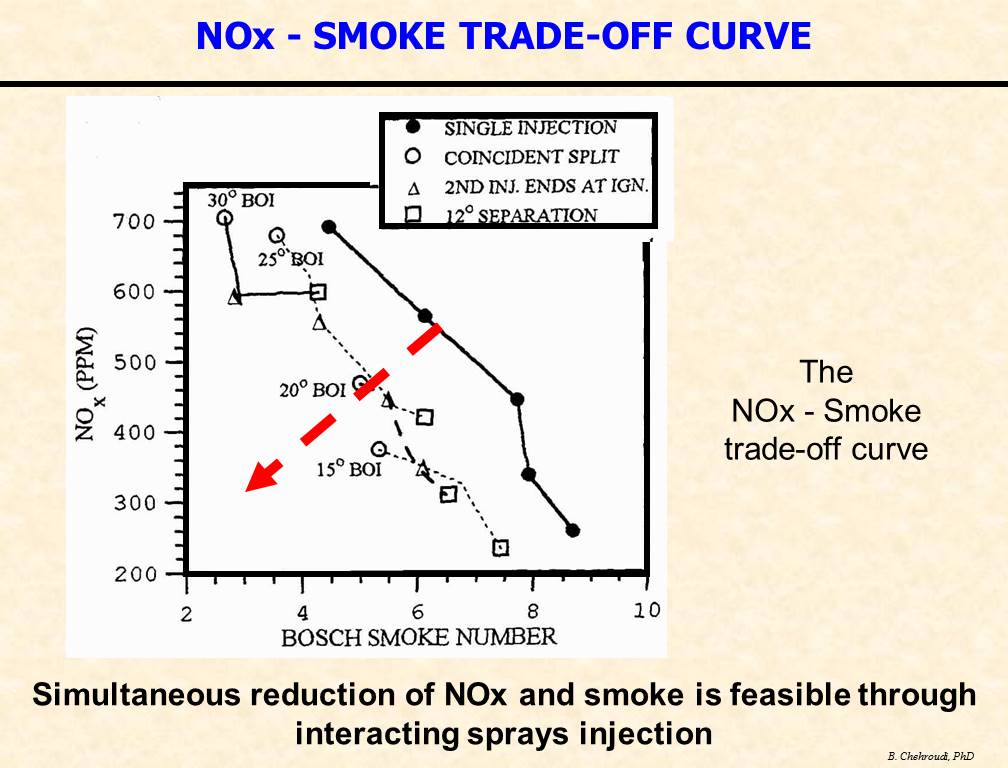

The images to

the right show an optically accessible engine for

combustion and flow studies using laser diagnostics such as

Laser Doppler Velocimeter (LDV), Phase Doppler Particle Analyzer

(PDPA, Exciplex method, high-speed visualization of in-cylinder

phenomena, and spectroscopy. The engine head can be readily

changed for either compression ignition (diesel) or spark

ignition (SI) engine studies.

Results have been published in the literature. For

example, see Schuh, D. and Chehroudi, B., 1992.

LDV Measurements

of Intake Port Flow in Two-Stroke Engine with and without

Combustion, Society of Automotive Engineers, 1992 Congress and

Exposition, SAE Transaction Paper 920424, February 24-28.

-

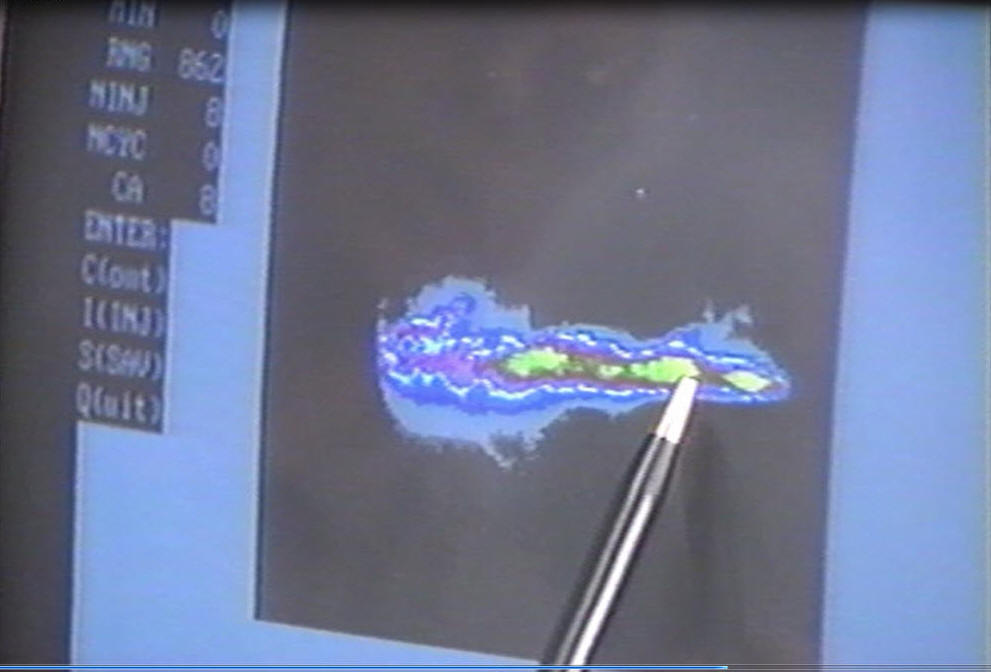

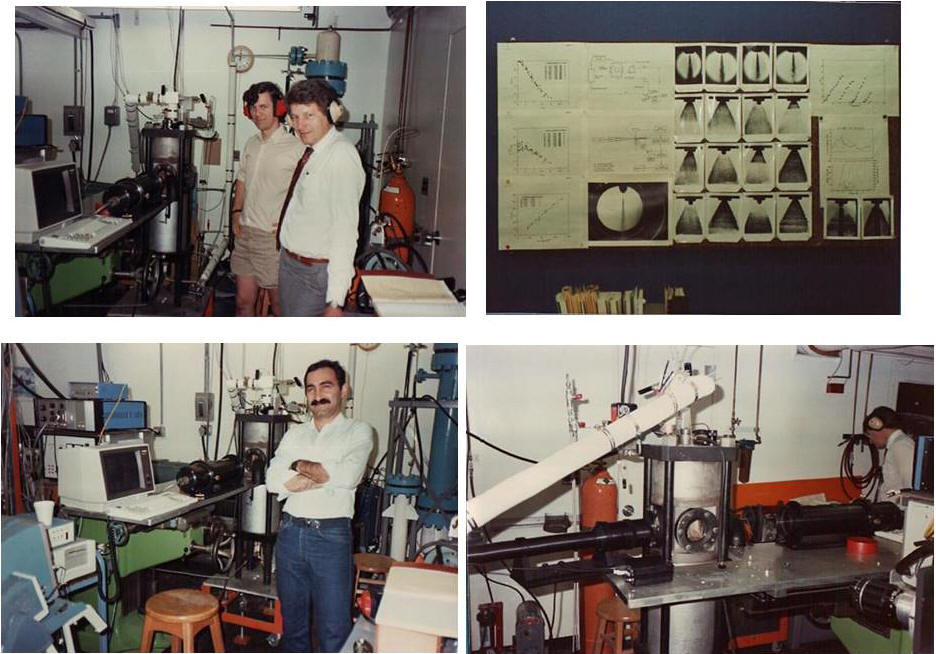

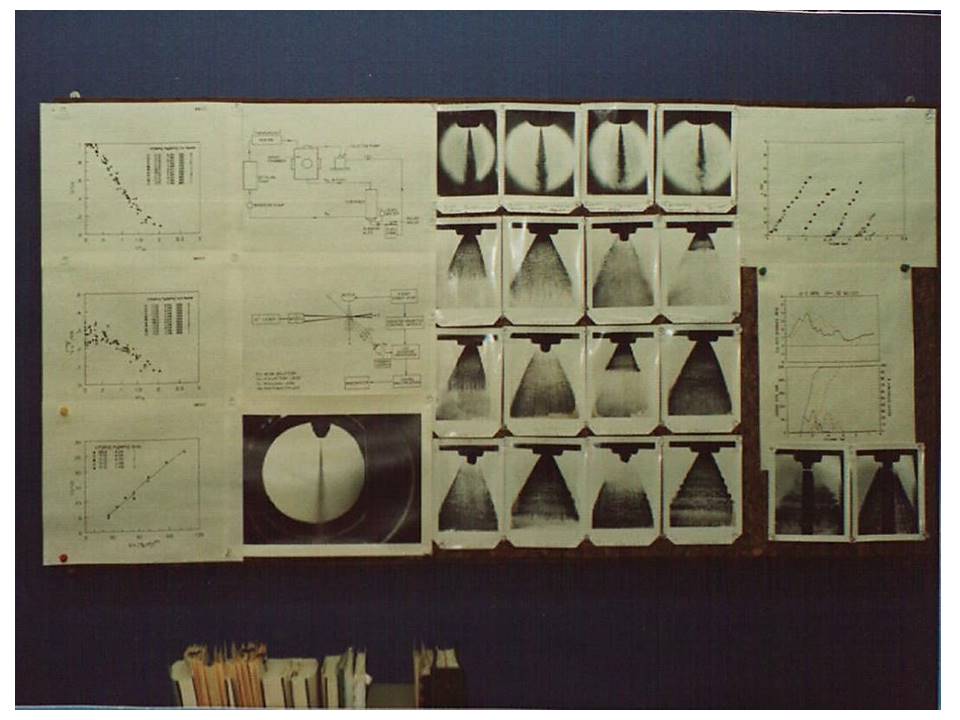

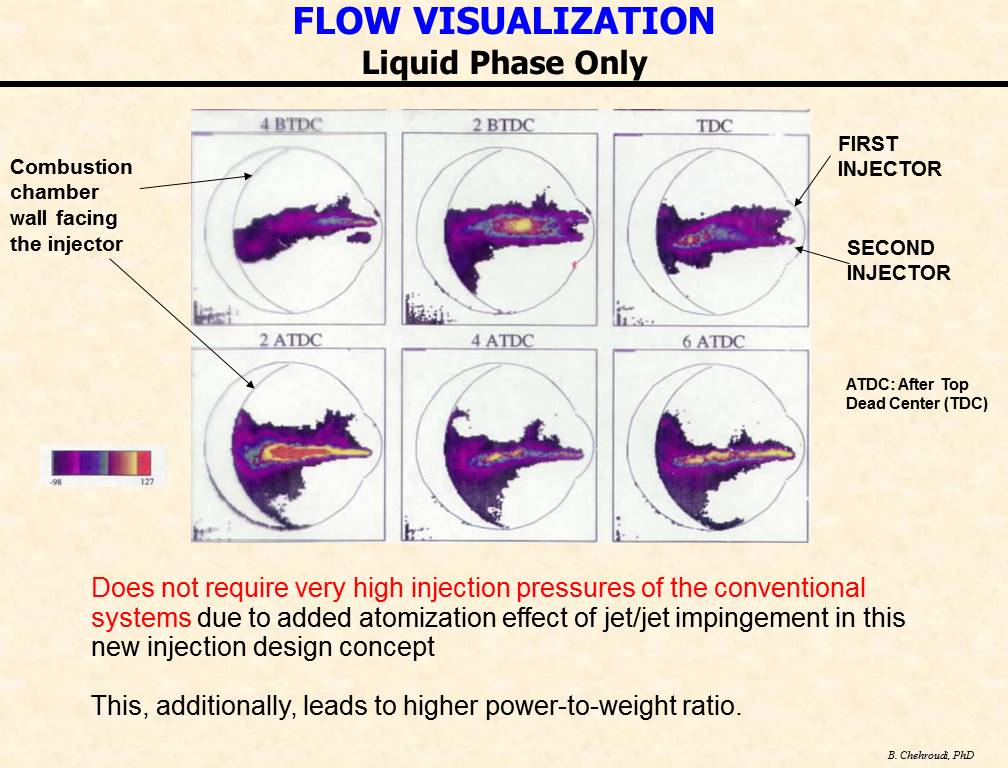

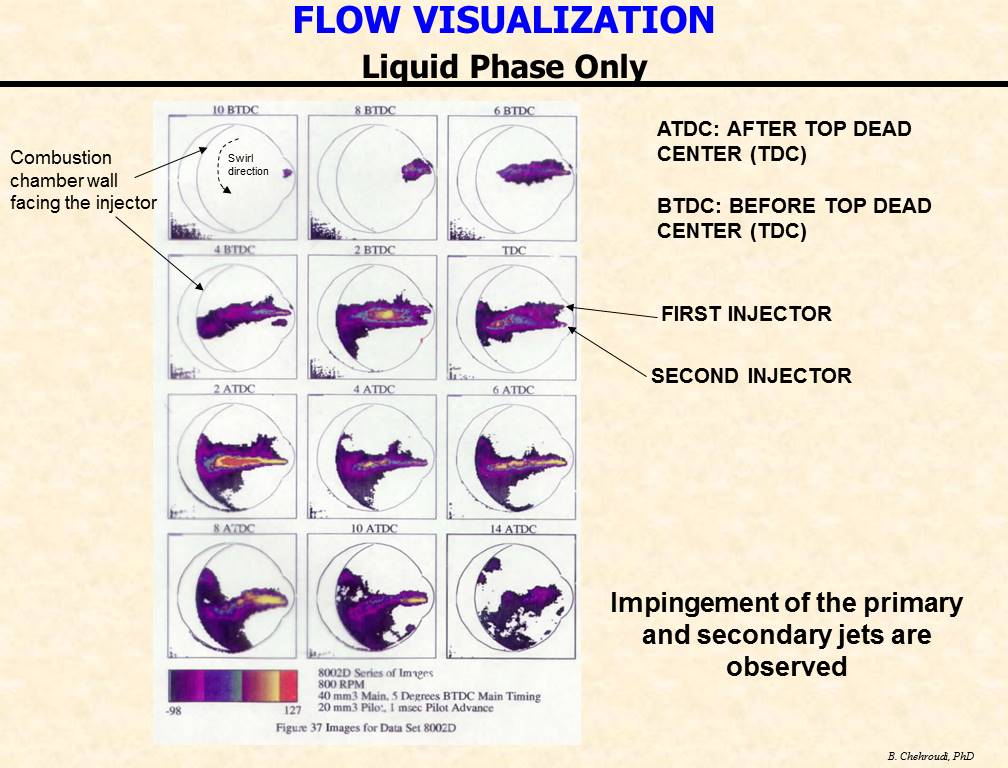

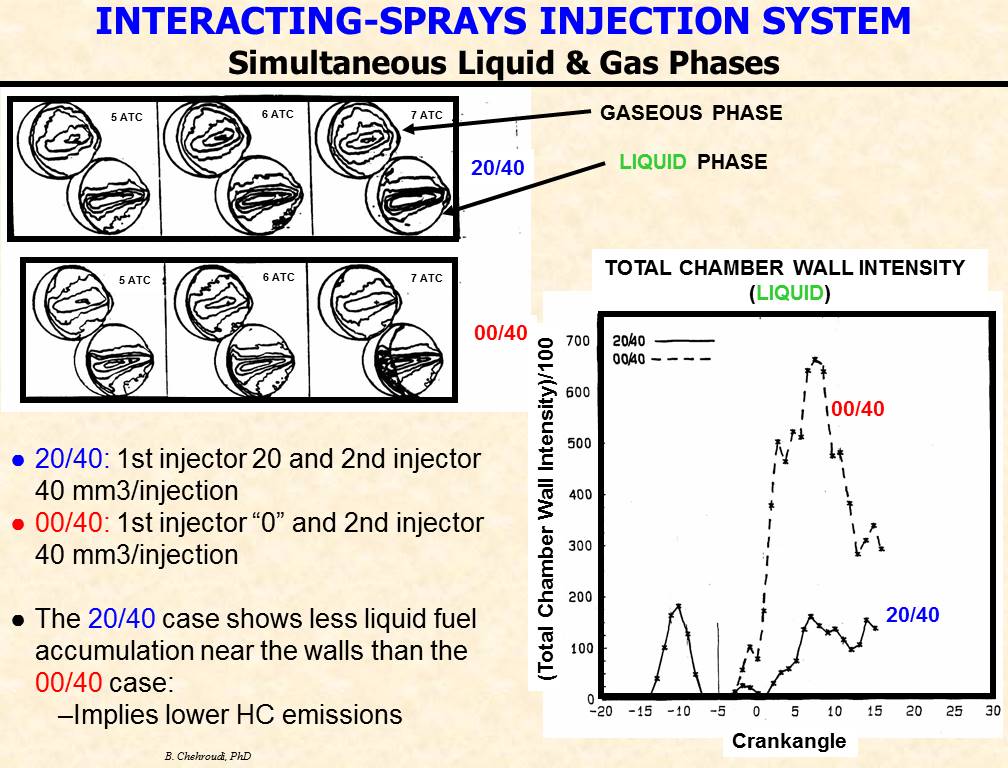

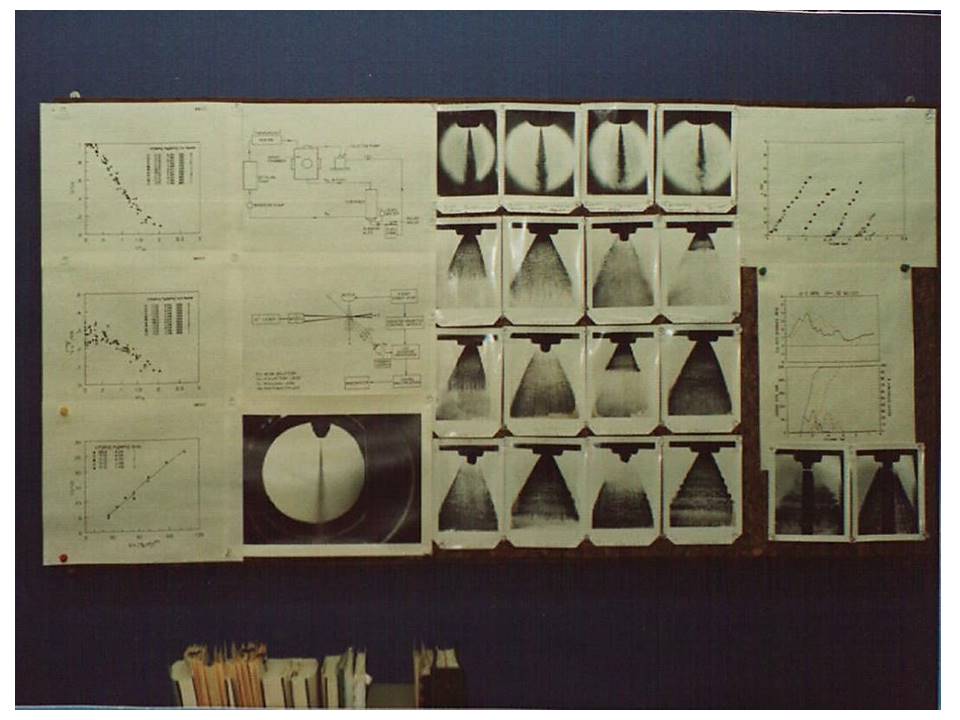

Sample images

acquired from a diesel-type spray (upper row) and

conically-opening poppet injector designed for Direct Injection

Stratified Combustion (DISC engine program) combustion studies

are shown.

The DISC program was a collaboration by General Motors Research

Laboratory, Princeton University Engine Research Laboratory, Los

Alamos National Laboratory, and Sandia Combustion Research

Facility sponsored the US Department of Energy (DOE).

-

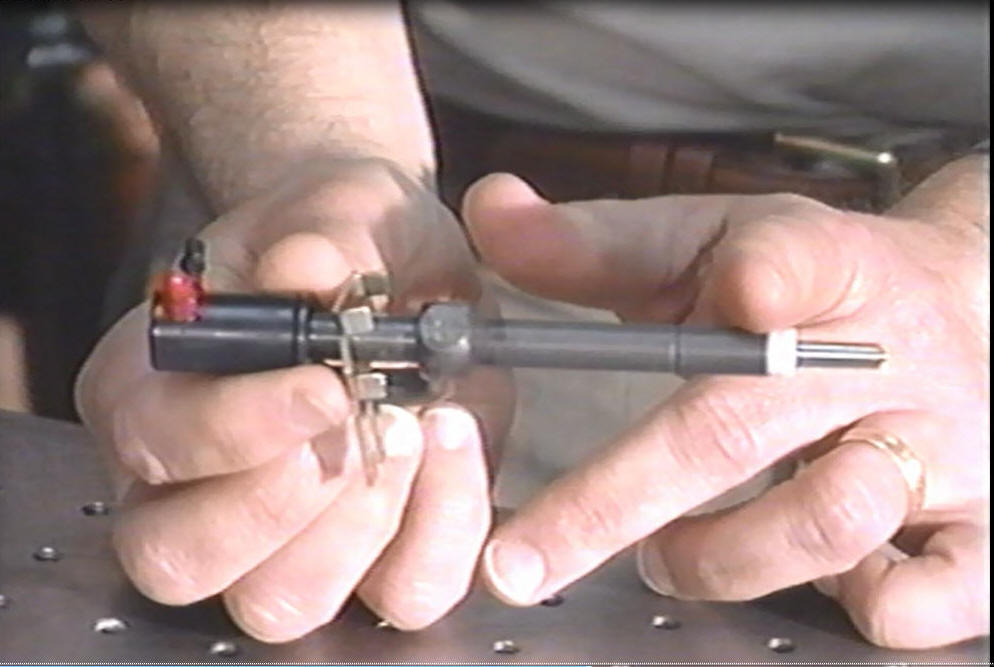

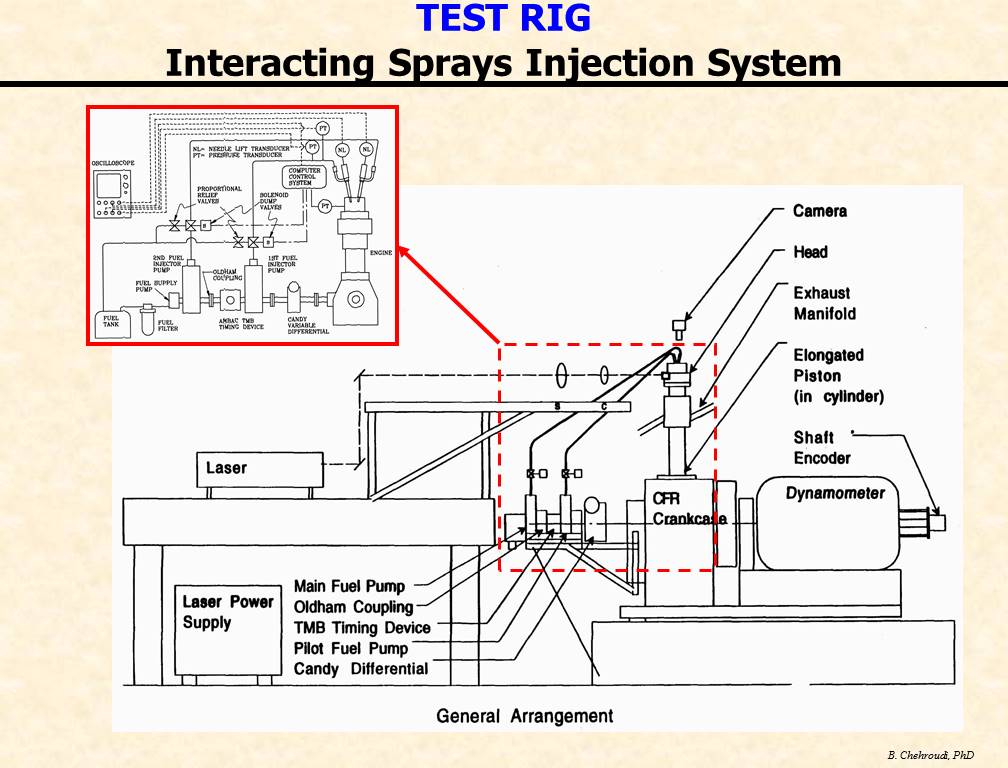

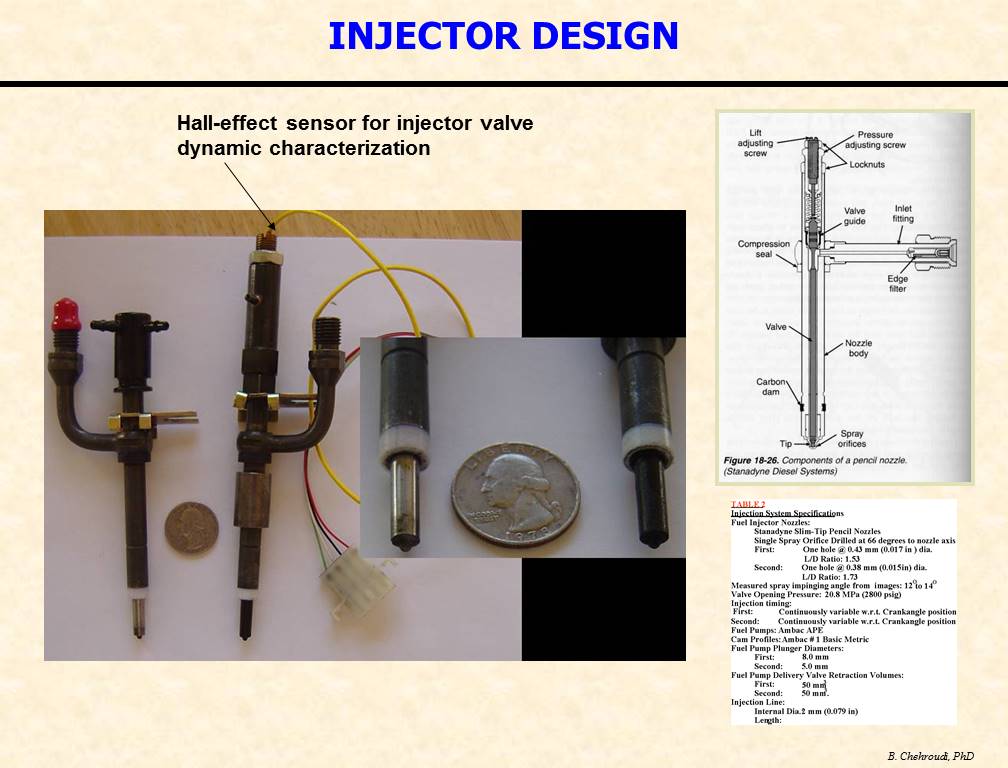

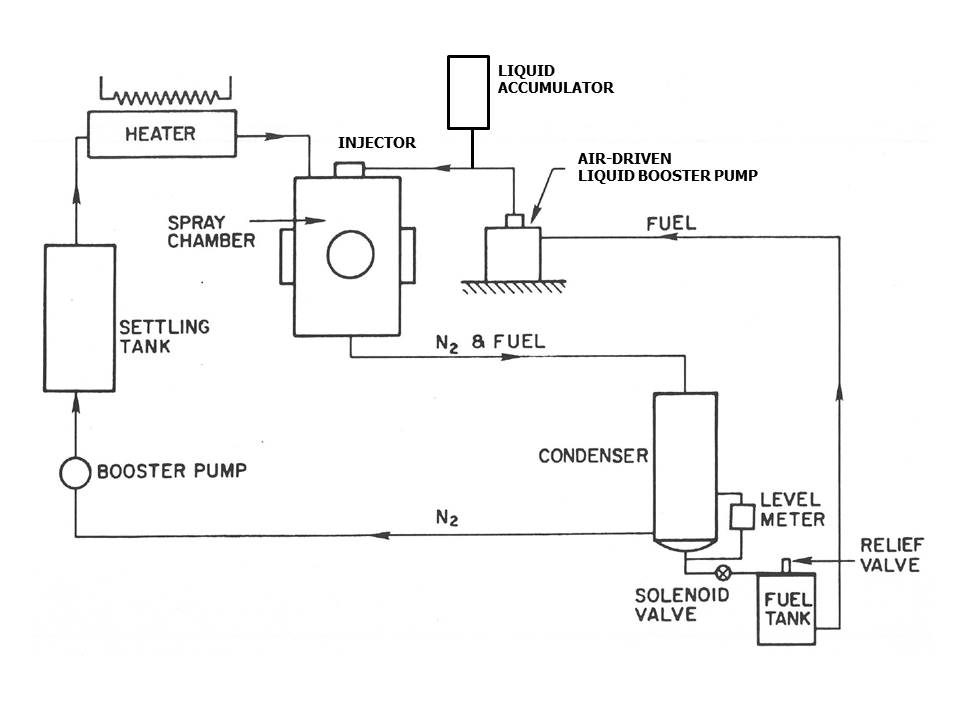

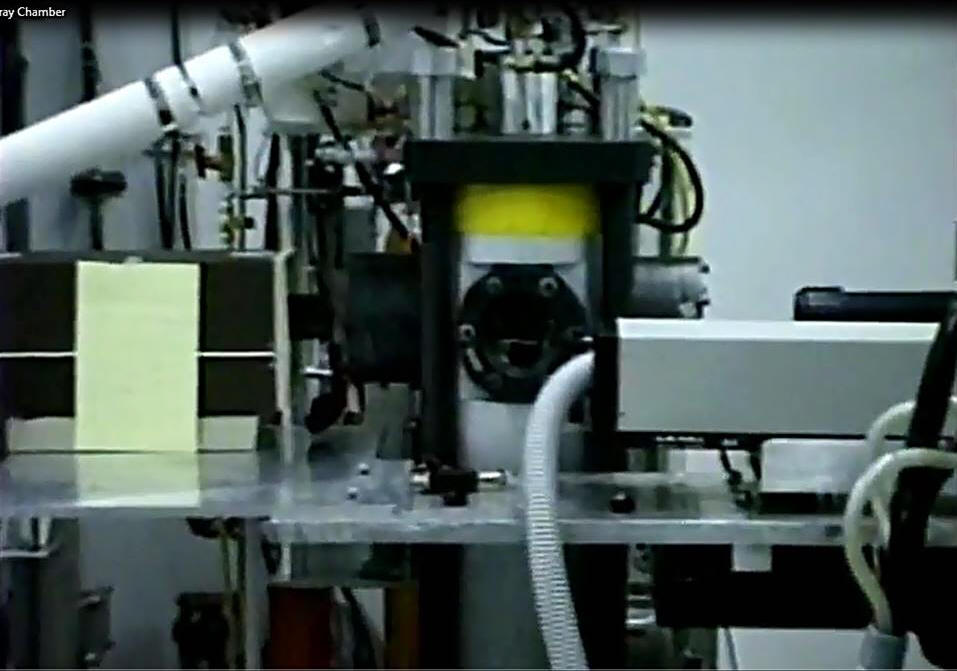

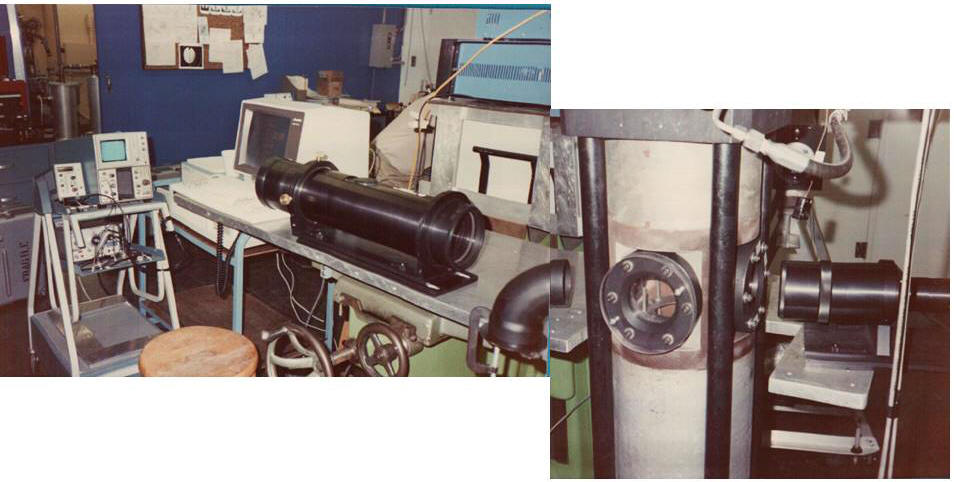

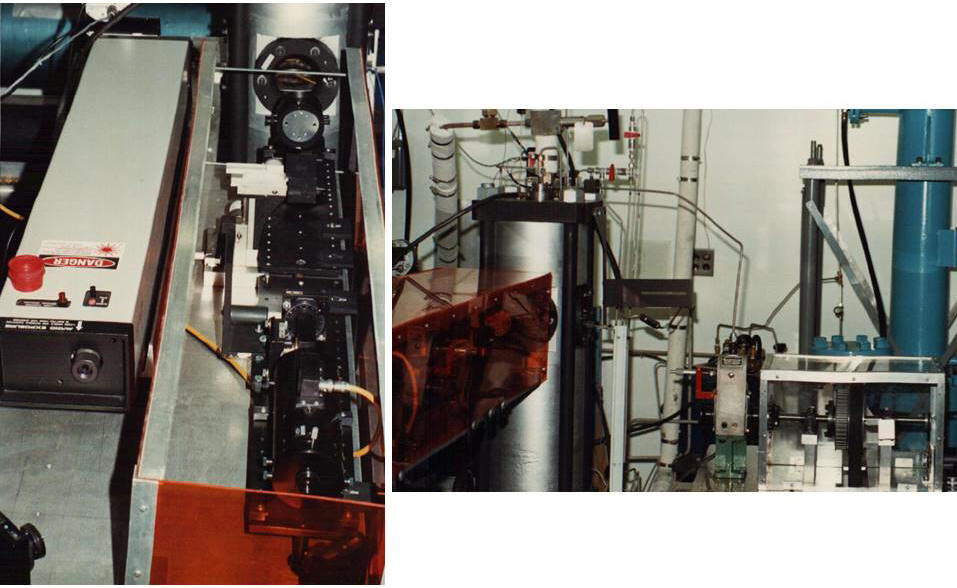

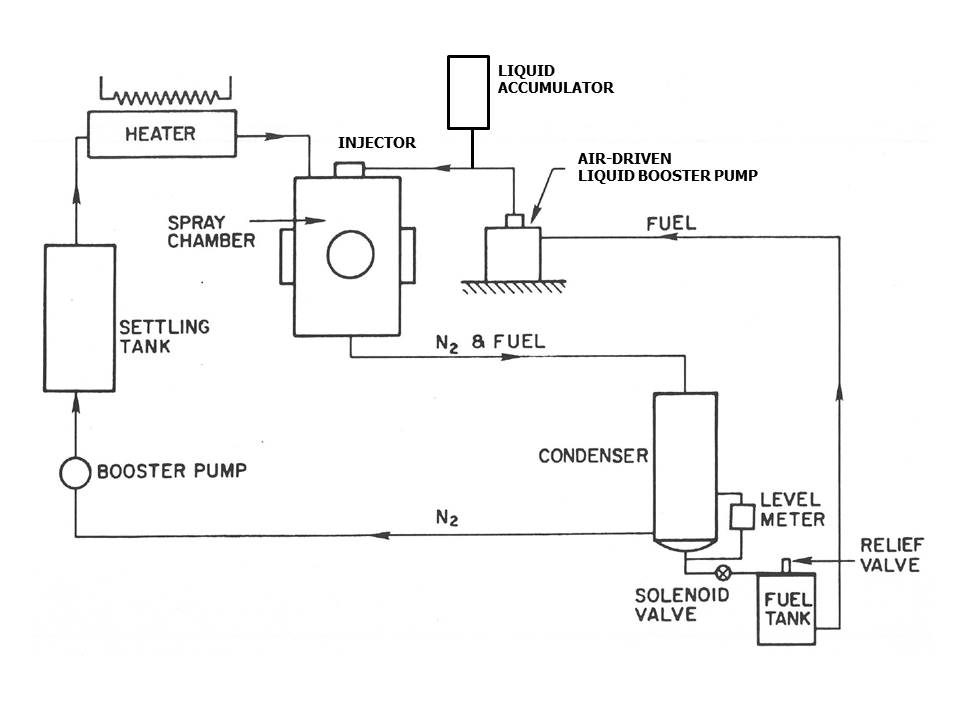

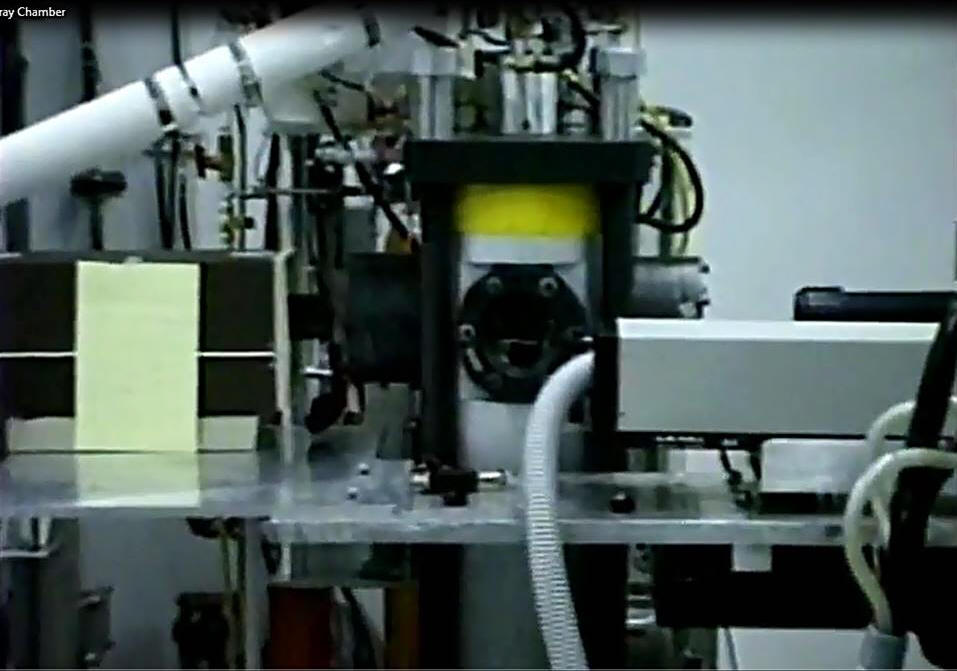

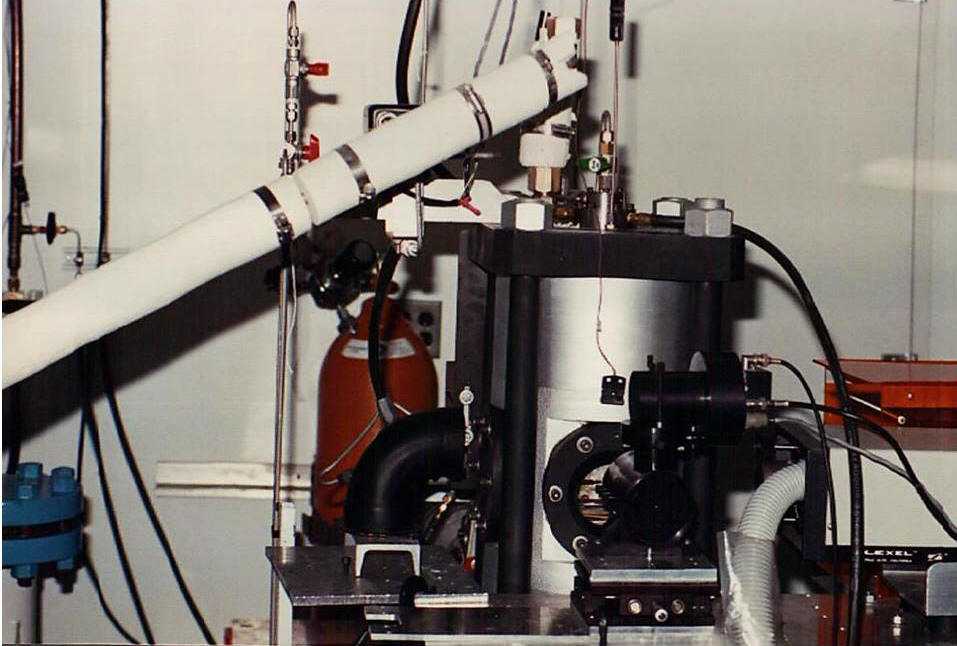

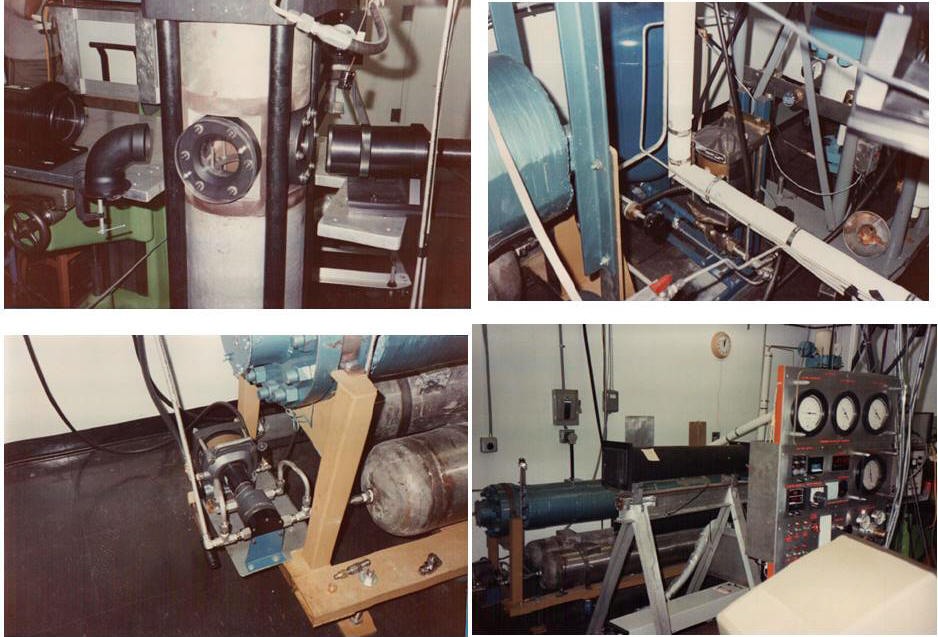

Images of the

high-pressure and temperature spray chamber for liquid

atomization and fuel injection research and development

are shown.

The pictures show a setup for laser optical diagnostics to

map spray droplet size and velocity fields. In

the movie clip, a setup for transient spray

characterization of a gasoline direct injection system by Ford

DFI-3 using a diffraction-based drop size distribution (by

Malvern) can be seen.

Results are published in the literature.

For example, see Laforgia, D, Chehroudi B. and Bracco, F. V.,

1989. Structure of Sprays from Fuel Injections - Part II, The

Ford DFI-3 Fuel Injector, Society of Automotive Engineers, 1988

Congress and Exposition, SAE Transaction Paper 890313, February

27- March 3.

Back to Top of

This Page

NOTE:

Contact Advanced Technology Consultants for consulting needs

and opportunities in this area.

Copyright 2017 -

Advanced Technology Consultants- All Rights

Reserved

|

%20&%20NOx%20%20reduction%20Diesel%20Chehroudi.jpg)