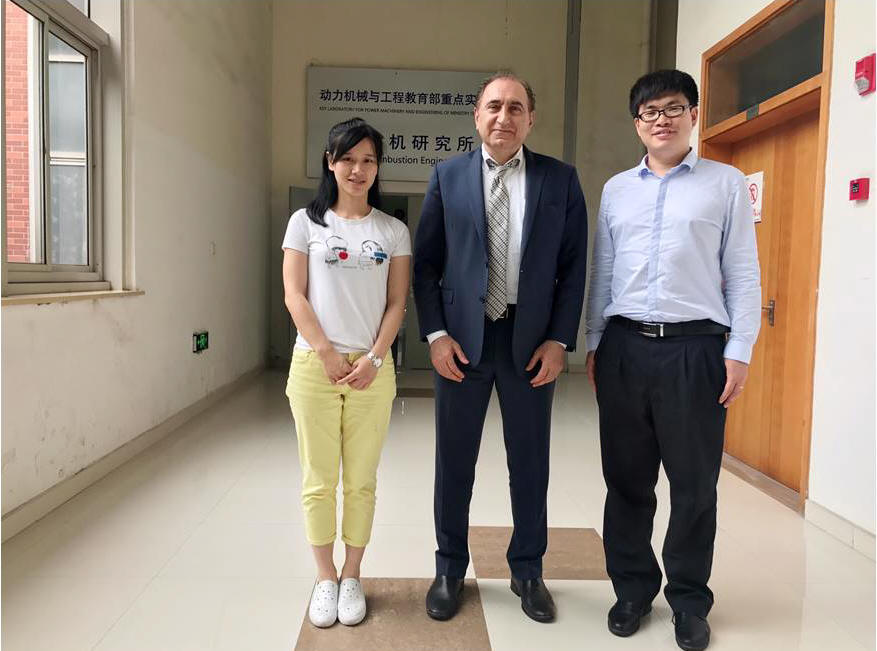

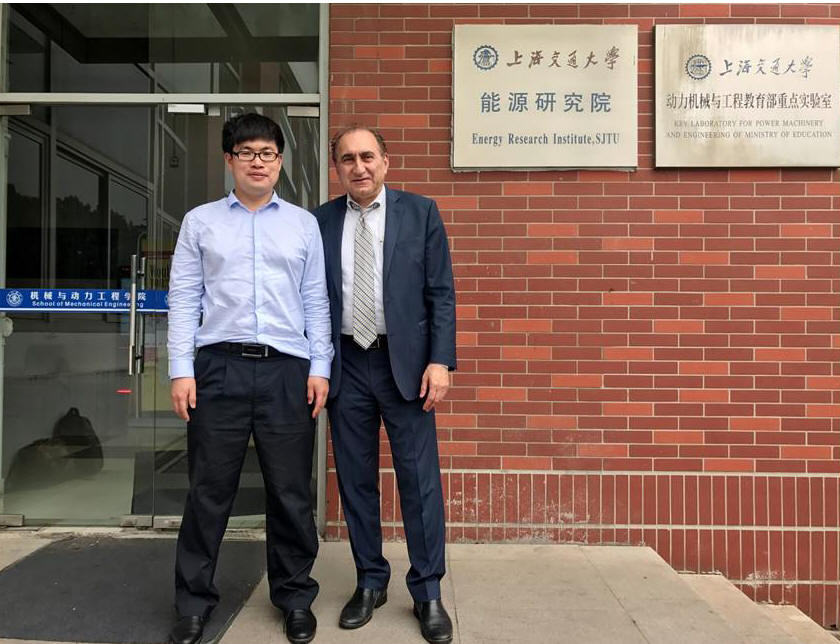

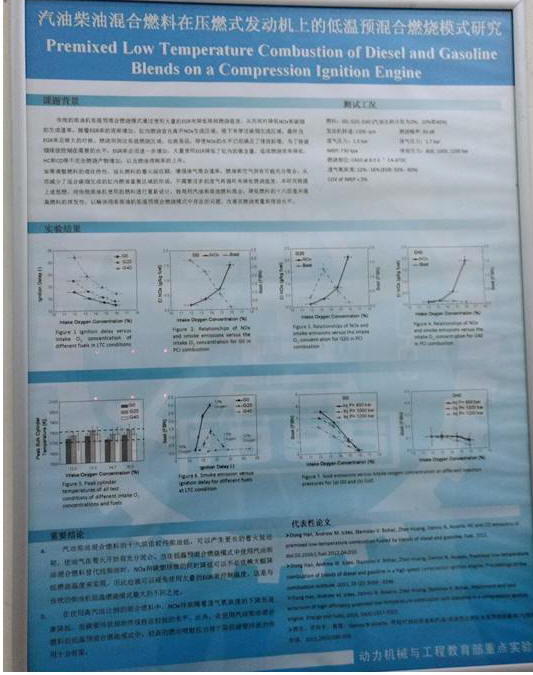

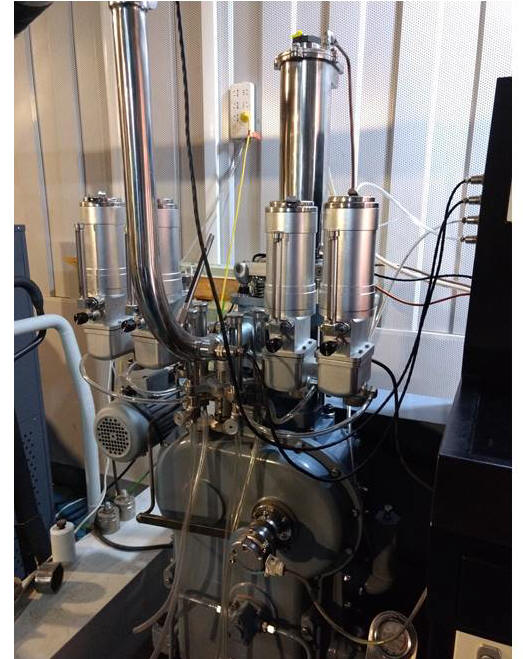

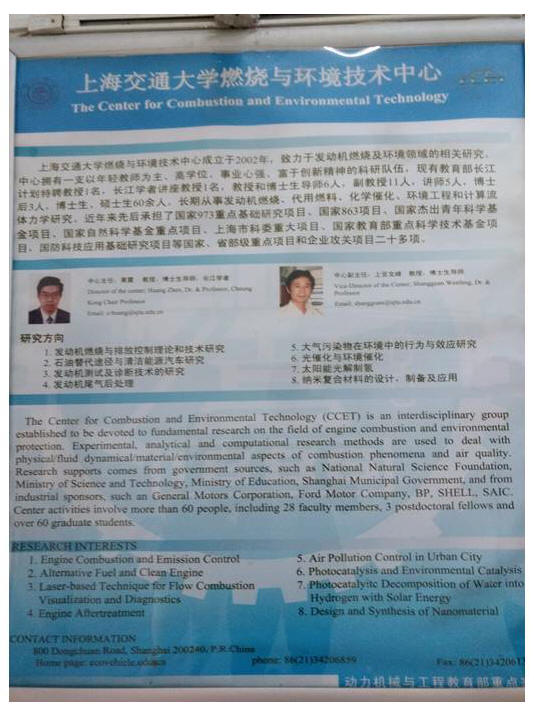

On May 31, 2018, Dr Chehroudi was

invited to visit Prof. Dong Han, Associate Professor and

Assistant Dean of the School of the Mechanical Engineering,

Institute of Internal Combustion Engine, at the

Shanghai Jiao Tong University (SJTU)

in Shanghai, China. The SJTU is ranked number 11

as "Best Global Universities for Engineering" by the

US News in 2018 with 37,288 students, 3,016 academic

staff, and 3,606/4,100/1,043 BA/MS/PhD degrees awarded each

year. Dr Han has received a MS degree from University of

Michigan at Ann Arbor, and a PhD at the Shangahi Jiao Tong

University. He has also spent two years at Princeton

University working with Prof. C. K. Law on a number of combustion

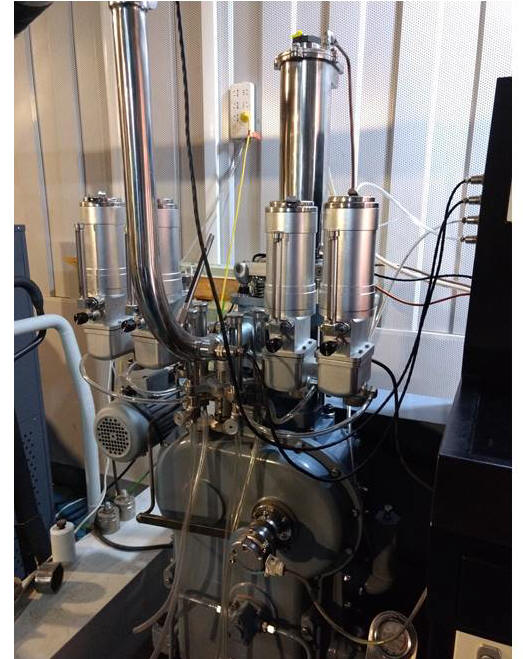

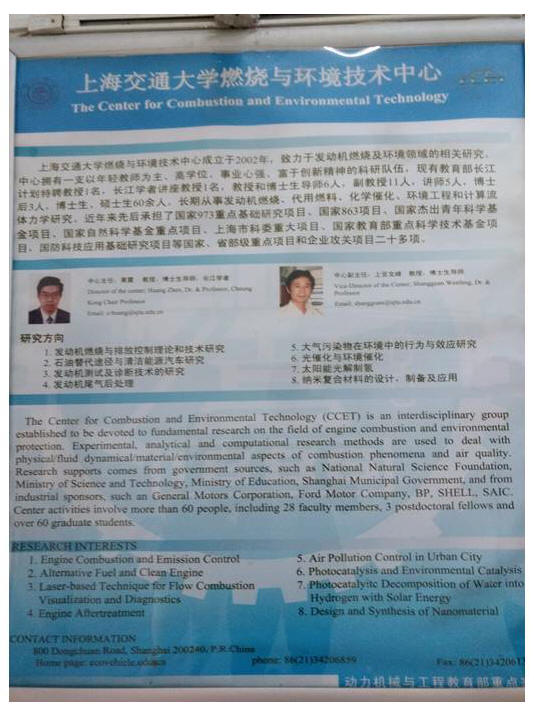

related projects. Dr Chehroudi was given a tour of the

department, graduate students offices and the combustion

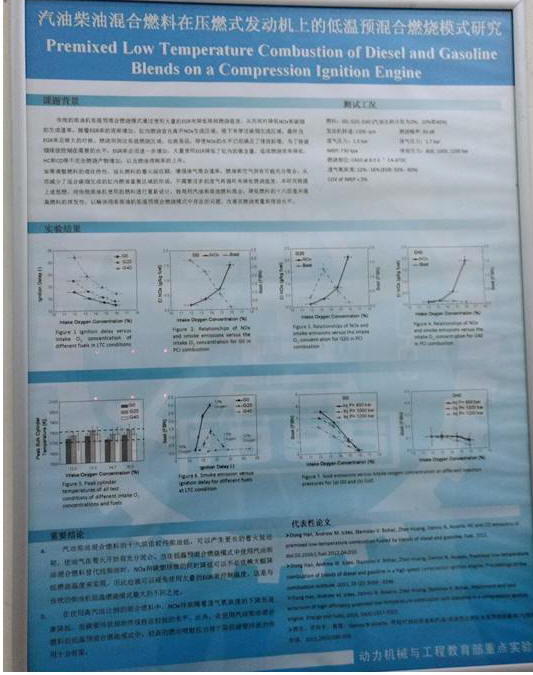

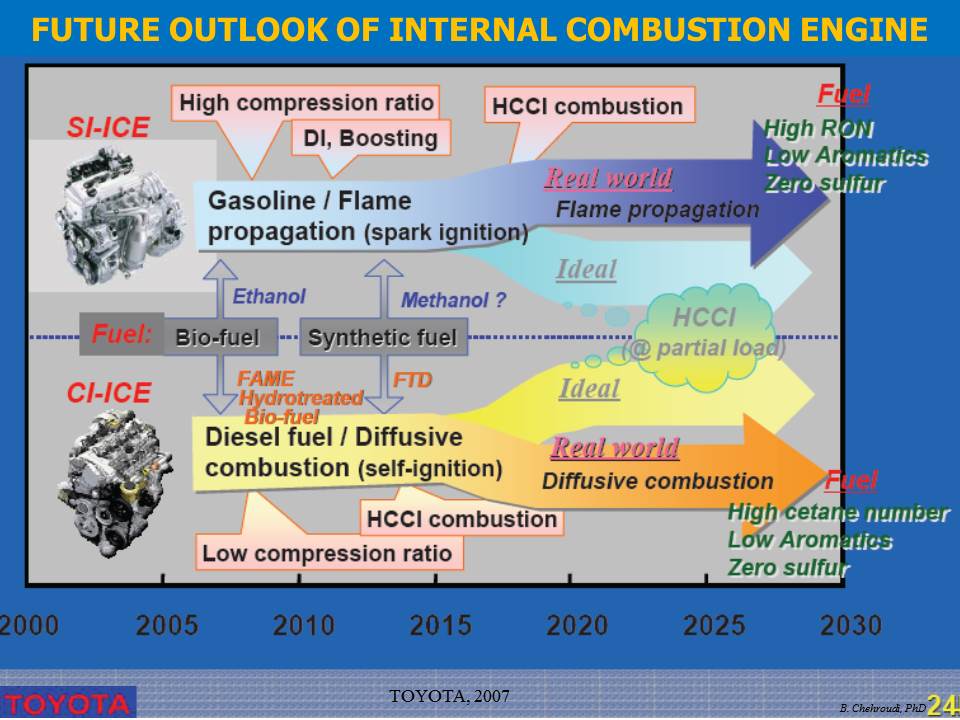

laboratories including the Internal Combustion Lab. A number

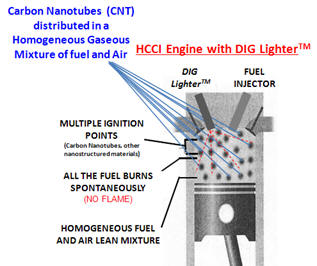

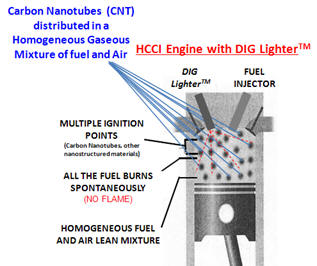

of research projects are going on in areas of HCCI engine and

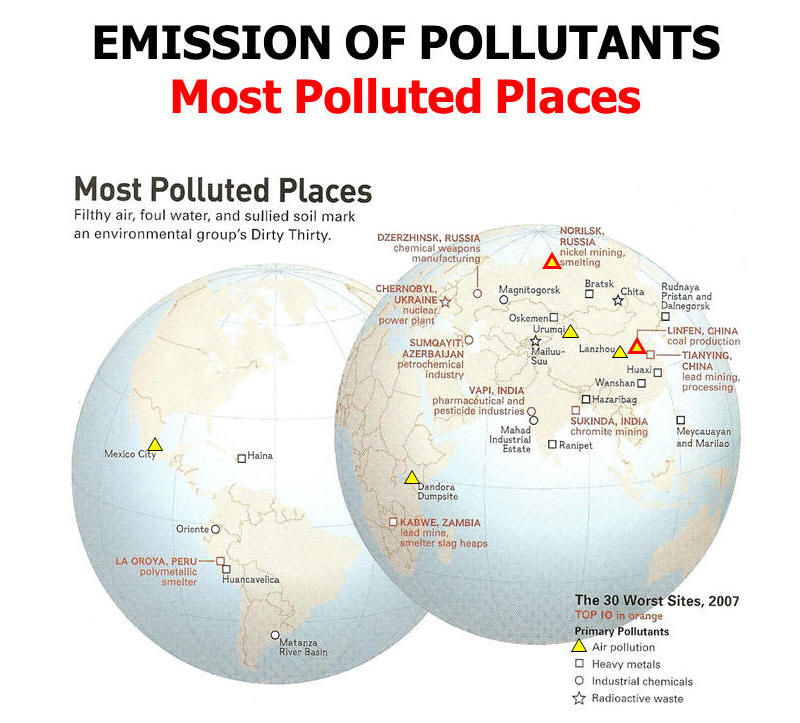

Low Temperature Combustion, fuel studies, and in general emission of

pollutants and performance improvements. Dr Han and Dr

Chehroudi has a number of conversations about their

experiences at Princeton University and a different topics

including future collaborations in research and education.

____________________________________

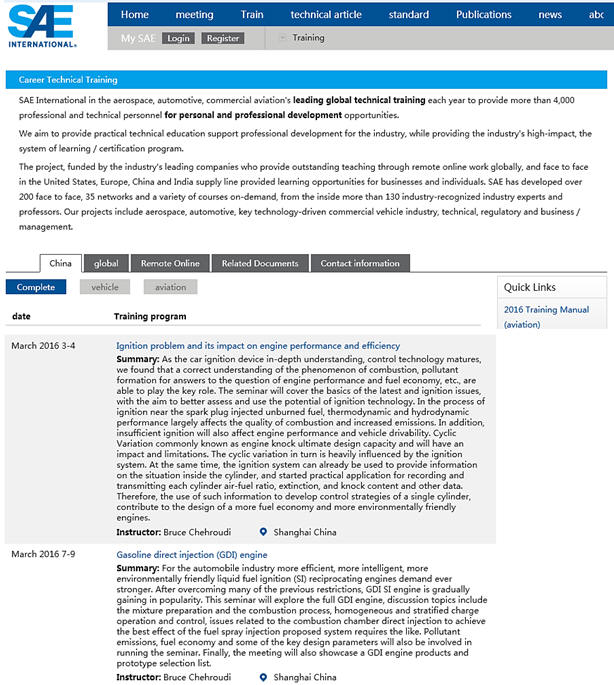

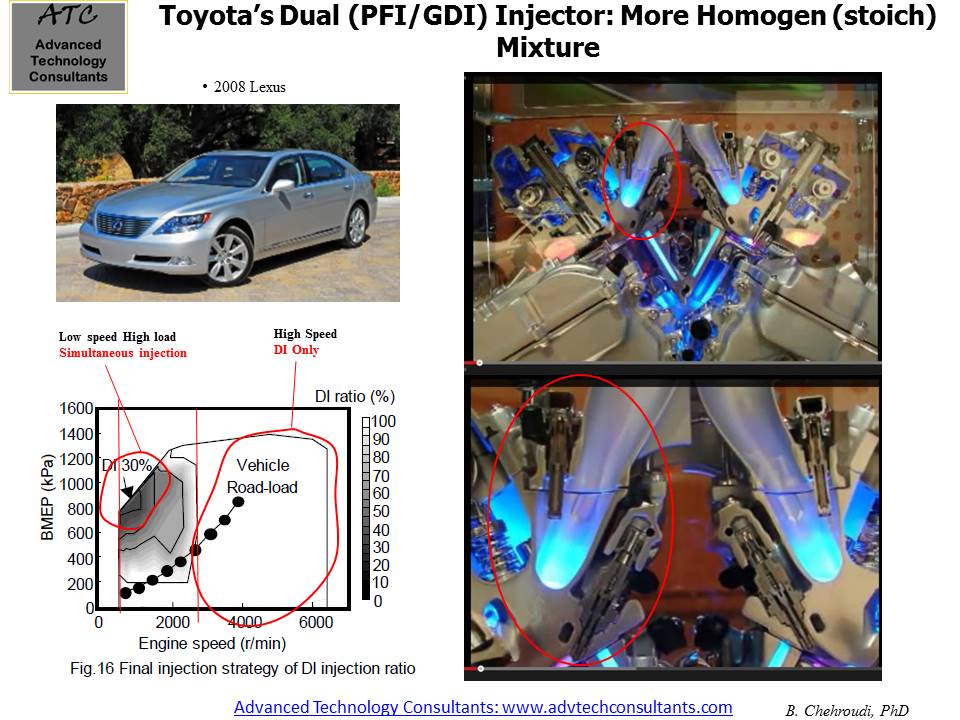

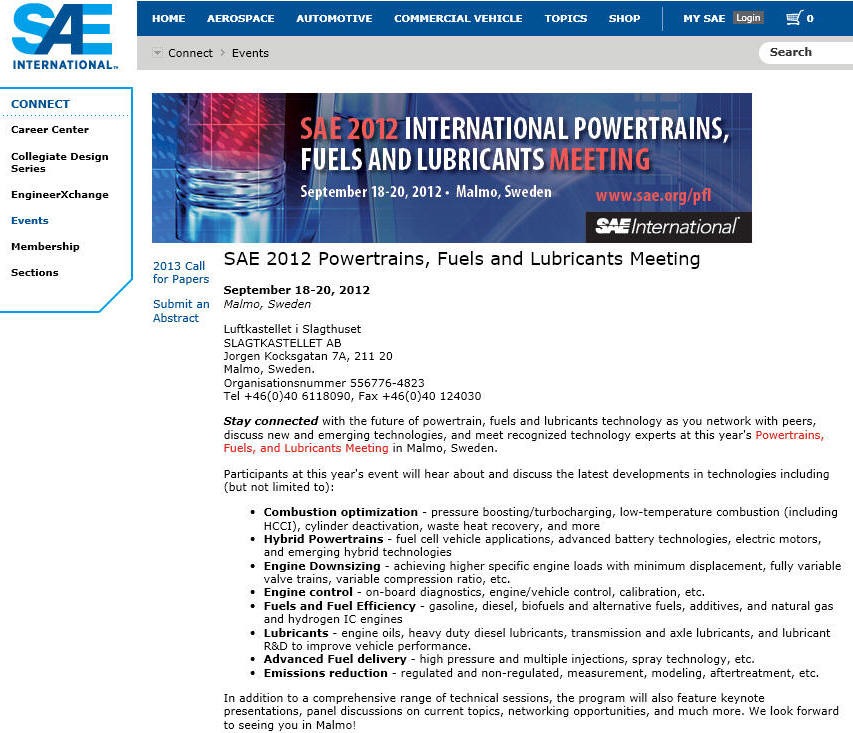

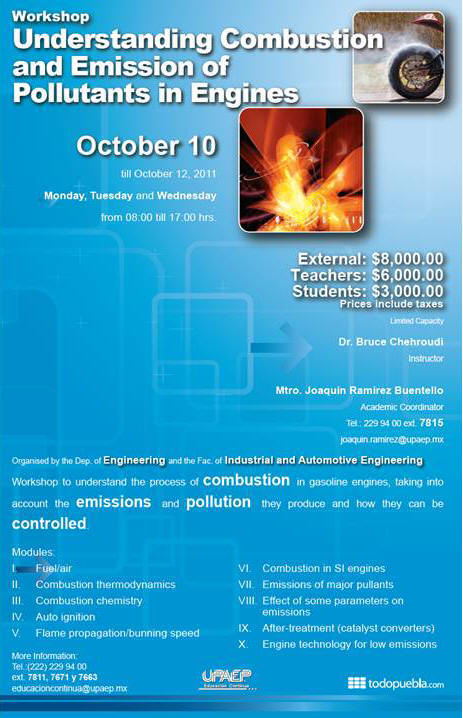

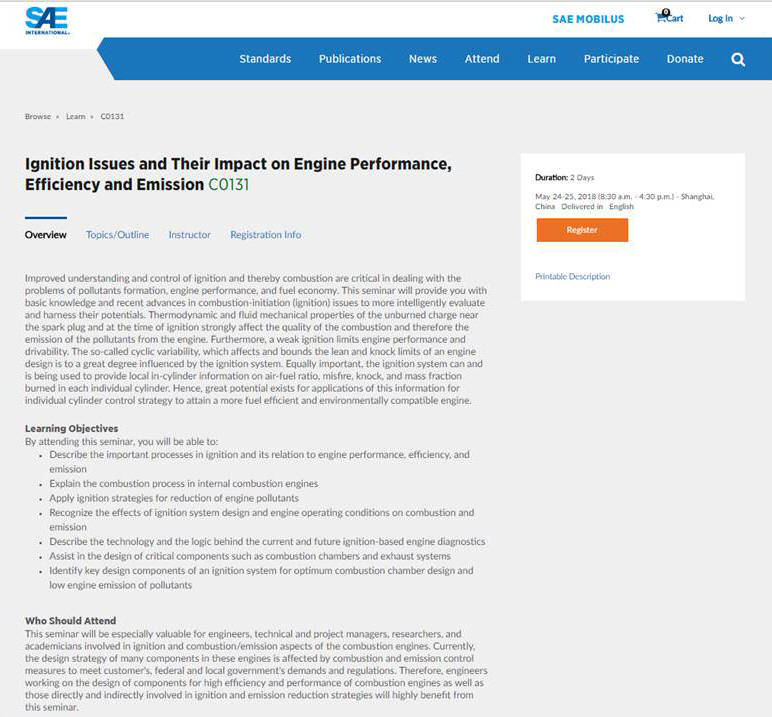

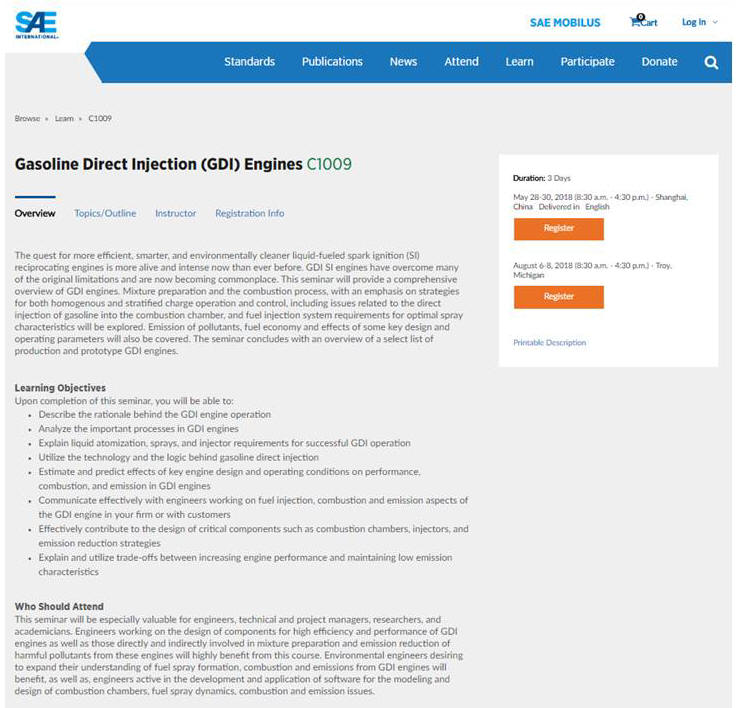

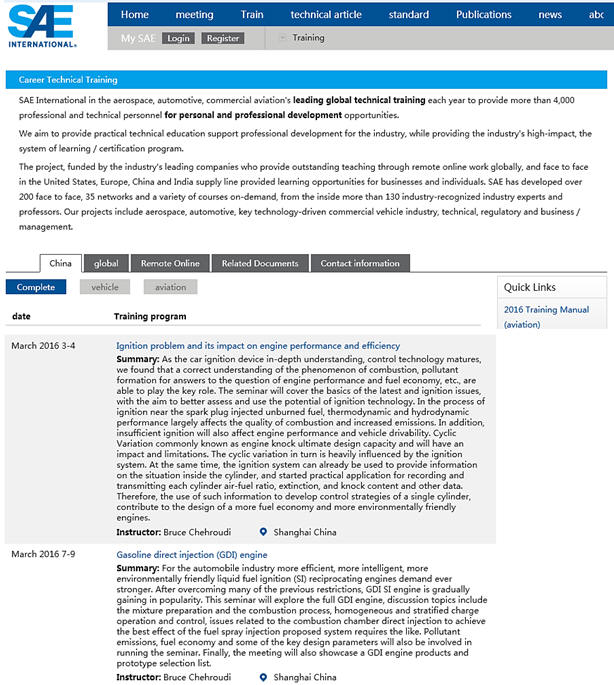

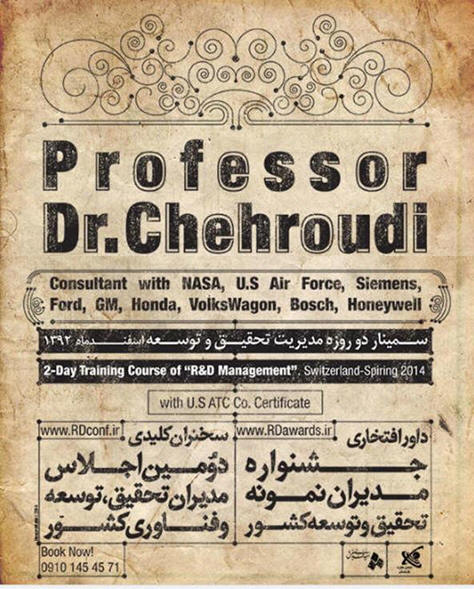

Dr Chehroudi is an invited speaker

by the Society of Automotive Engineers in Shanghai, China

to present lectures on

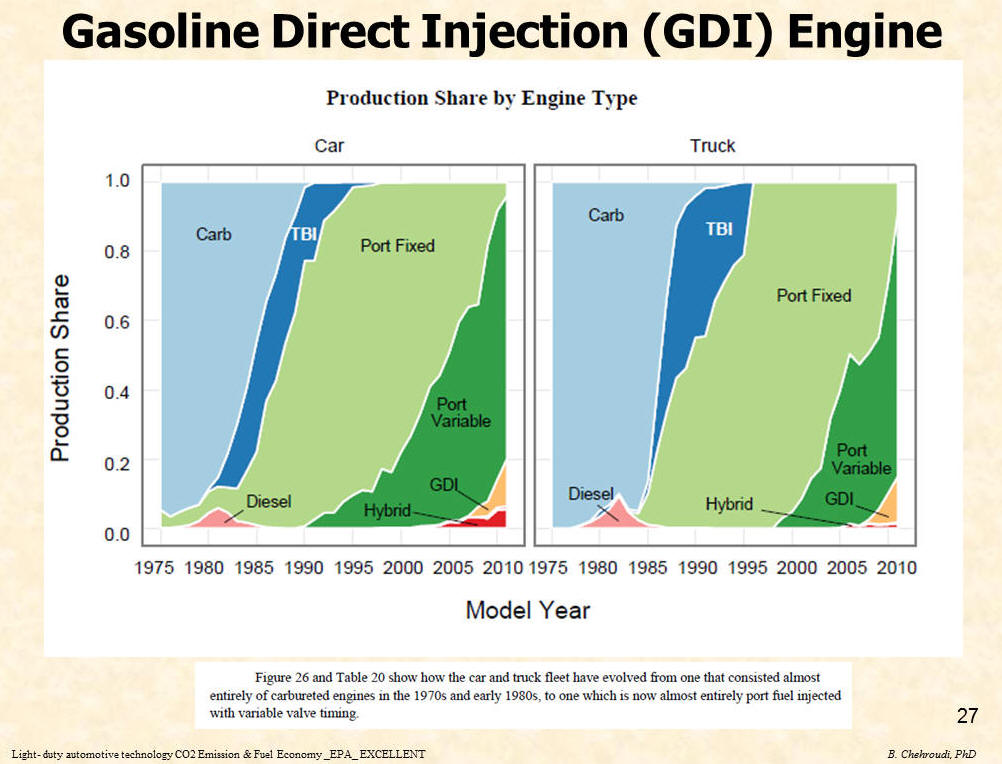

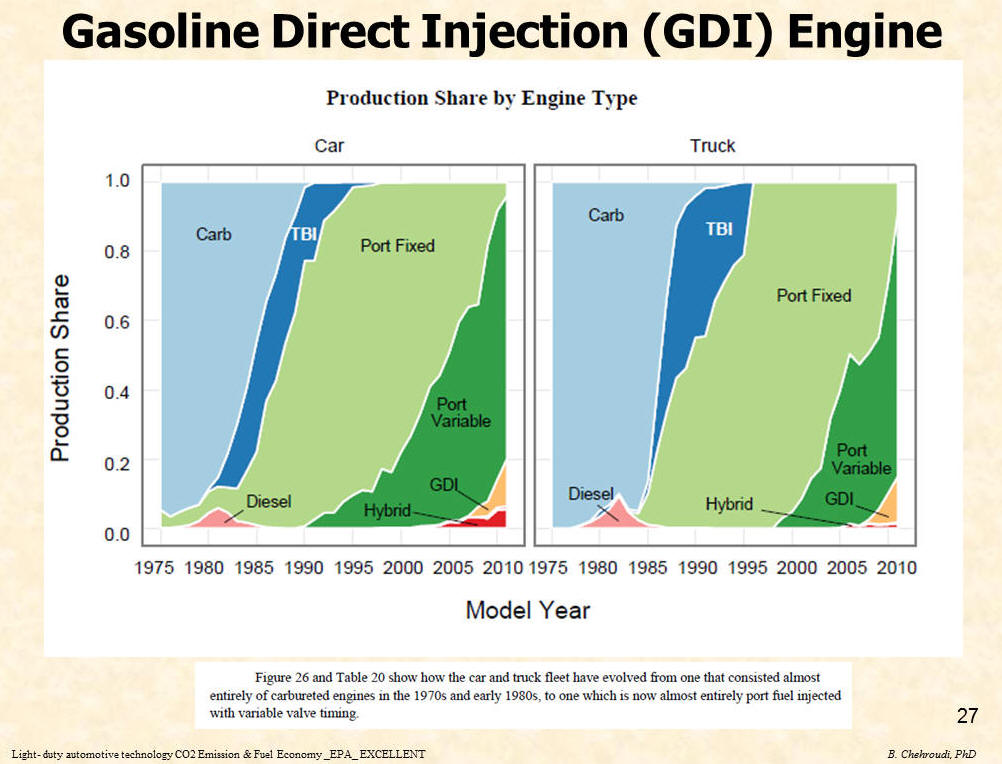

Gasoline

Direct Injection (May 28-30, 2018) and

Ignition Issues and Their Impact on Engine Performance, Efficiency

and Emission (May 24-25, 2018).

Attendees are from corporations,

government, and universities. There will be several meetings with

top executives and university leaders to discuss areas of mutual

interest and collaborations.

About IGENG News:

https://www.reuters.com/finance/stocks/companyProfile/FENG.N

____________________________________

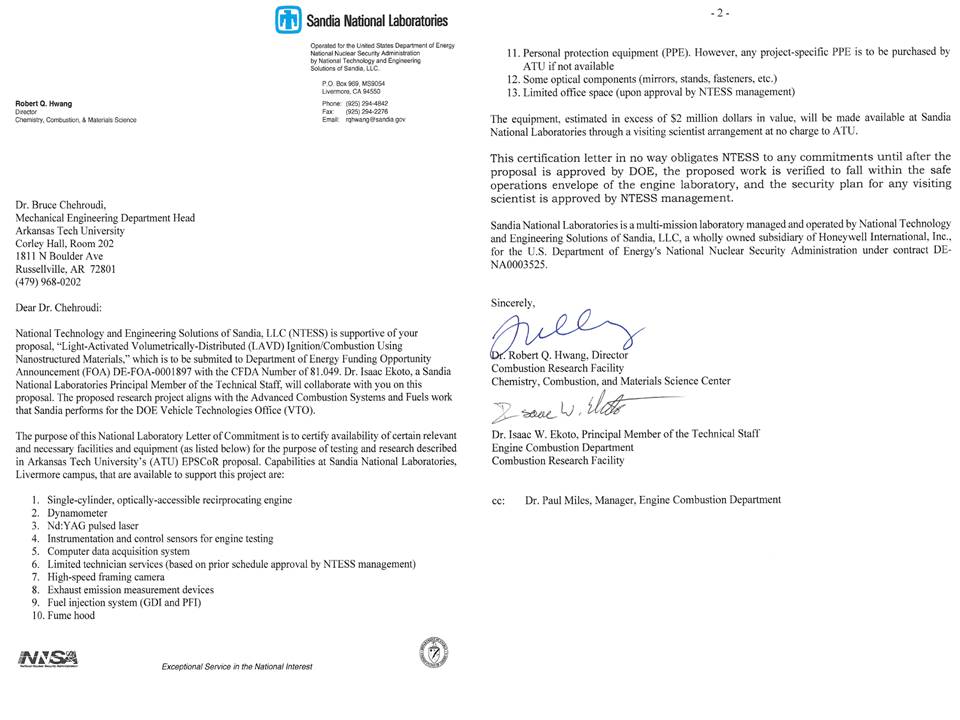

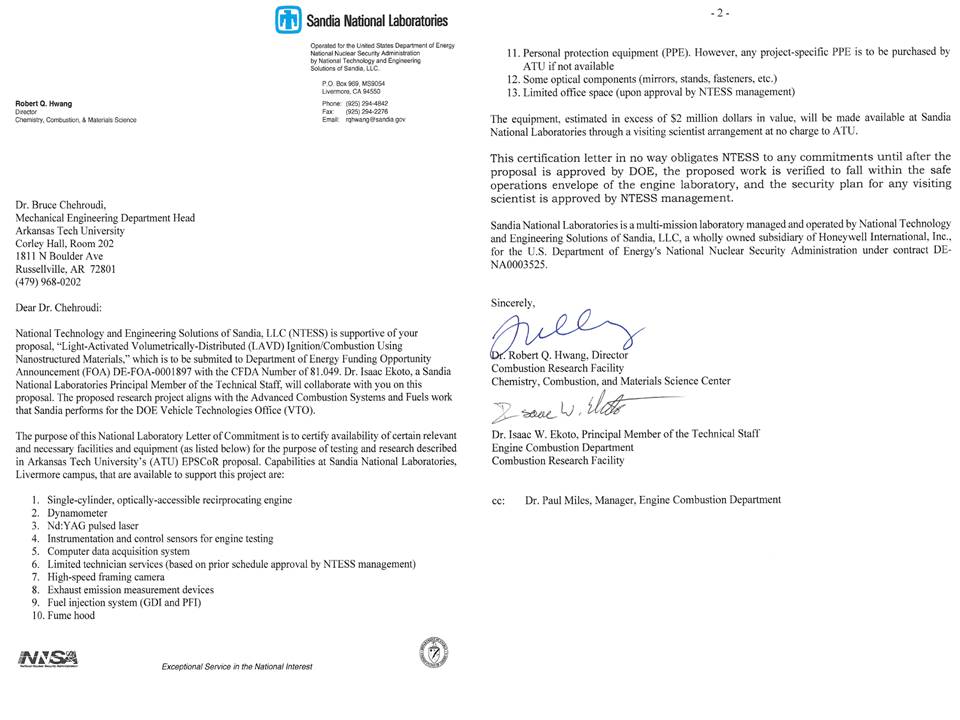

On May 16, 2018, Dr Chehroudi has submitted a ~$600,000 proposal to the Department of

Energy to further develop his two ground-breaking patents in the

hot area of nanotechnology. These patents were filed thirteen years ago with

numerous applications from automotive to medical industries. They

are a synergy between nanotechnology, chemical reaction, and optics.

He further developed them during the years working at Air Force

Research Laboratory (AFRL) and later through SBIR funds. For the

last month, virtually all weekends Dr Chehroudi was occupied

preparing this 3-year $600,000 proposal with over $2 million

equipment support and commitment from SANDIA Combustion Research

Facility (CRF). SANDIA-CRF is the top engine combustion research

laboratory in the world. Many well-known and respected

scientists/researchers in the world have some activity with CRF at a

time in their careers. The Letter-of-Commitment is only written if

the project is judged to be innovative, ground-breaking, has the

potential to become a disruptive technology, and aligned with what

CRF is currently researching. To help junior faculty members, Dr.

Chehroudi put the name of one of his junior faculty members (Dr

Ehsan Hosseini) as a Principal Investigator on this proposal for

him, as a young professor, to grow, and be

more successful.

nanotechnology. These patents were filed thirteen years ago with

numerous applications from automotive to medical industries. They

are a synergy between nanotechnology, chemical reaction, and optics.

He further developed them during the years working at Air Force

Research Laboratory (AFRL) and later through SBIR funds. For the

last month, virtually all weekends Dr Chehroudi was occupied

preparing this 3-year $600,000 proposal with over $2 million

equipment support and commitment from SANDIA Combustion Research

Facility (CRF). SANDIA-CRF is the top engine combustion research

laboratory in the world. Many well-known and respected

scientists/researchers in the world have some activity with CRF at a

time in their careers. The Letter-of-Commitment is only written if

the project is judged to be innovative, ground-breaking, has the

potential to become a disruptive technology, and aligned with what

CRF is currently researching. To help junior faculty members, Dr.

Chehroudi put the name of one of his junior faculty members (Dr

Ehsan Hosseini) as a Principal Investigator on this proposal for

him, as a young professor, to grow, and be

more successful.

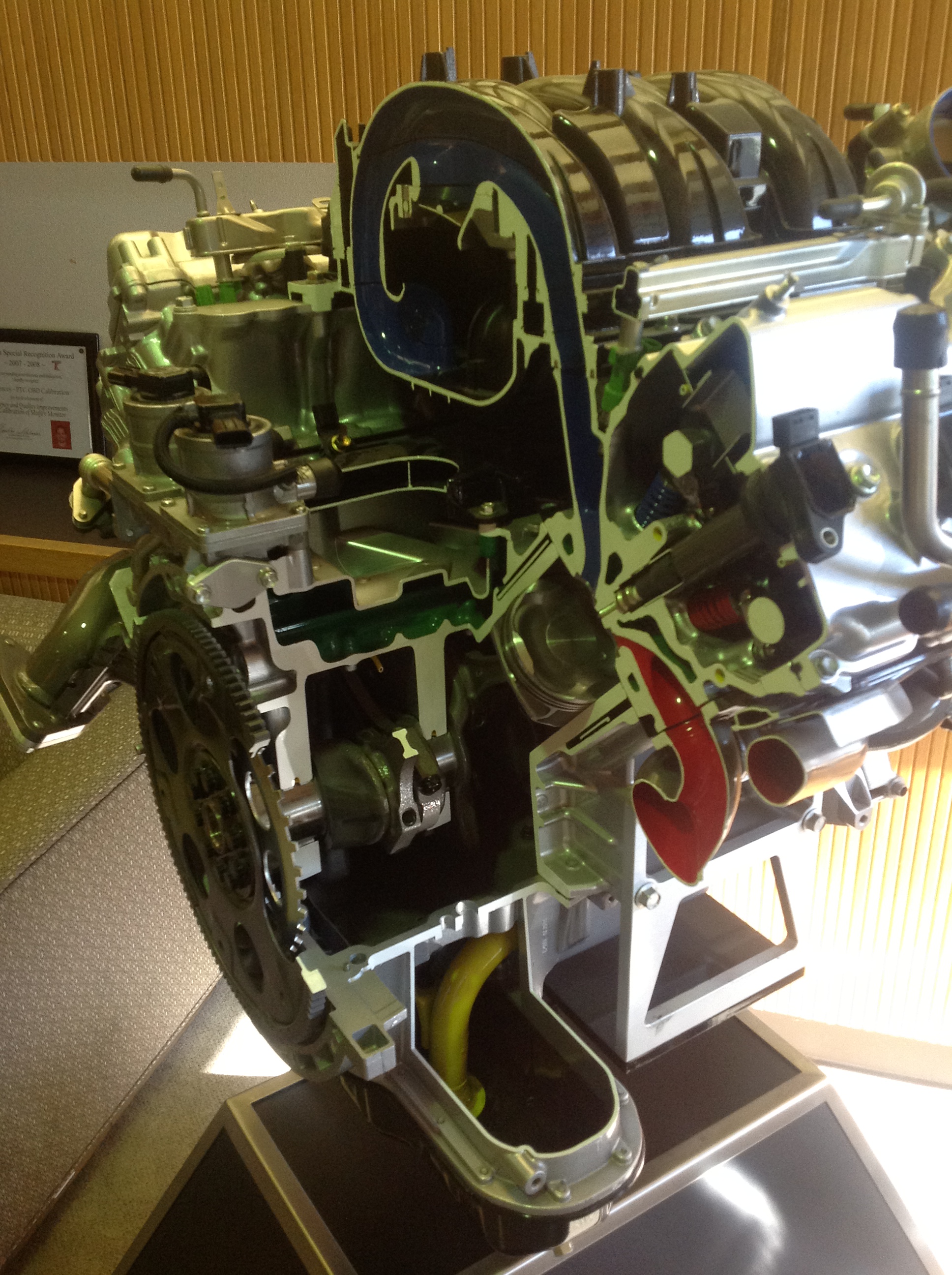

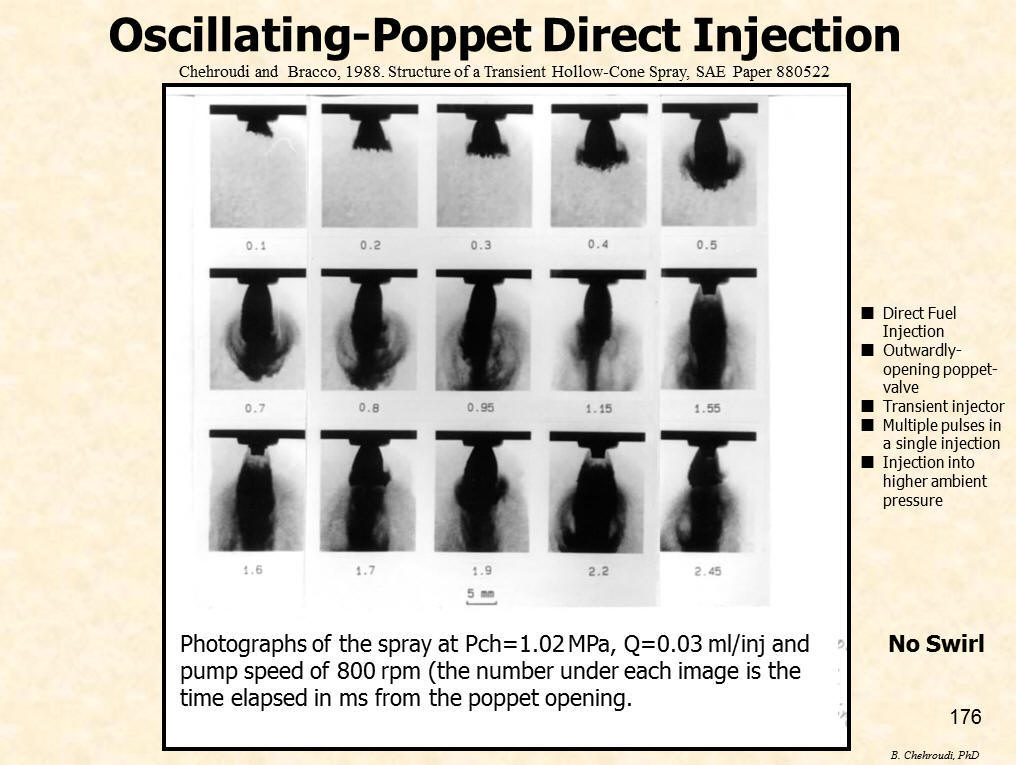

In early 90s, Dr Chehroudi has worked

with SANDIA CRF for over five years on Direct Injection Stratified

Charge (DISC) engine when he was at Princeton

University and through a consortium consisting of SANDIA_CRF,

Department of Energy, Los Alamos Laboratory, General Motors Research

Laboratory, and Princeton University.

For a sample of Dr Chehroudi's work

on Nanotechnology see the following links:

1.

Supercritical Fluids: Nanotechnology and Select Emerging

Applications

2.

Graphene and Combustion Applications

3.

Activation and control of Autoignition in HCCI Engine

4.

Potential

Application of Photo-thermal Volumetric Ignition of Carbon Nanotubes

in Internal Combustion Engines.

Project Summary

Light-Activated Volumetrically-Distributed (LAVD)

Ignition/Combustion Using Nanostructured Materials

Statement of the problem or situation

that is being addressed:

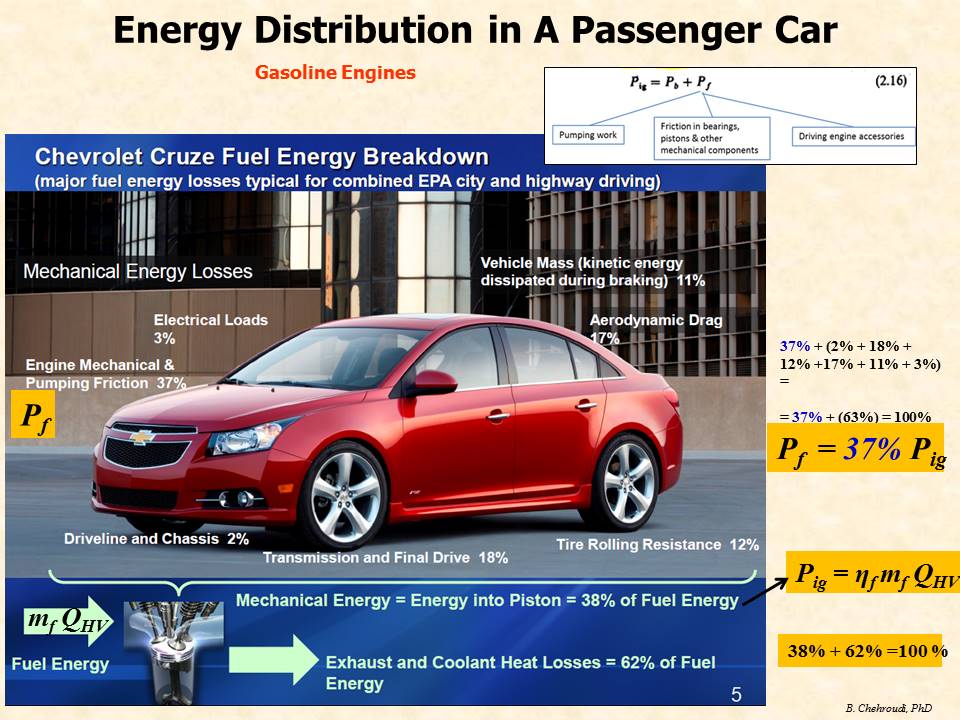

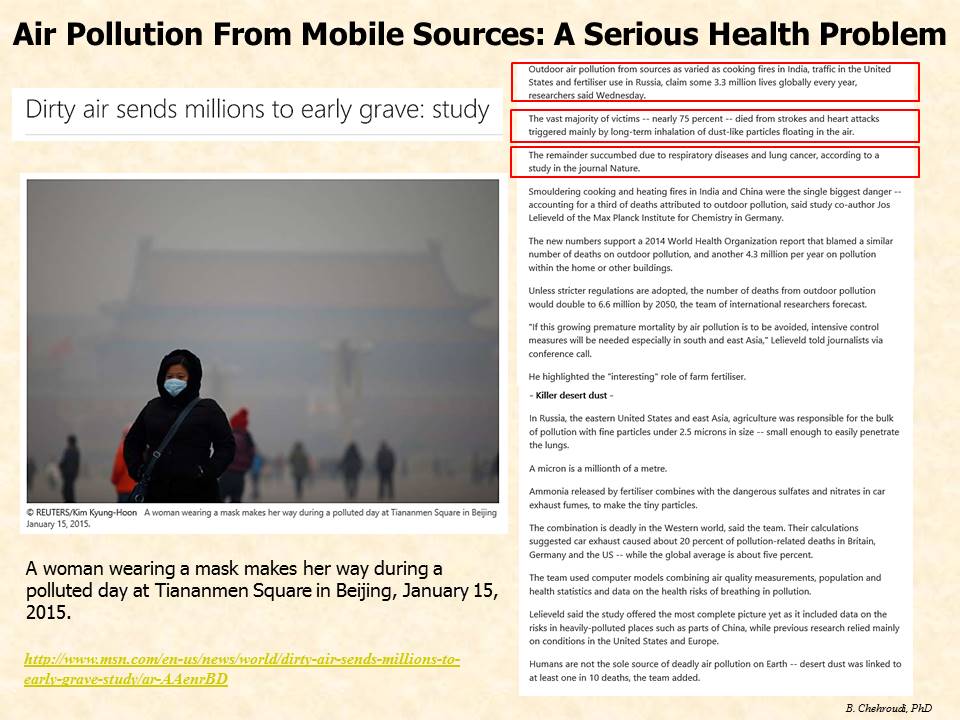

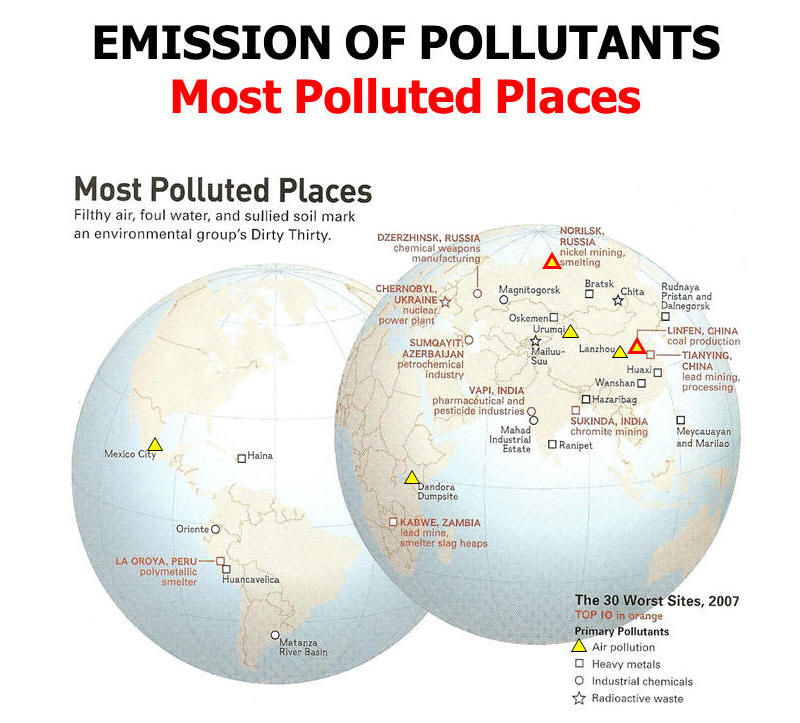

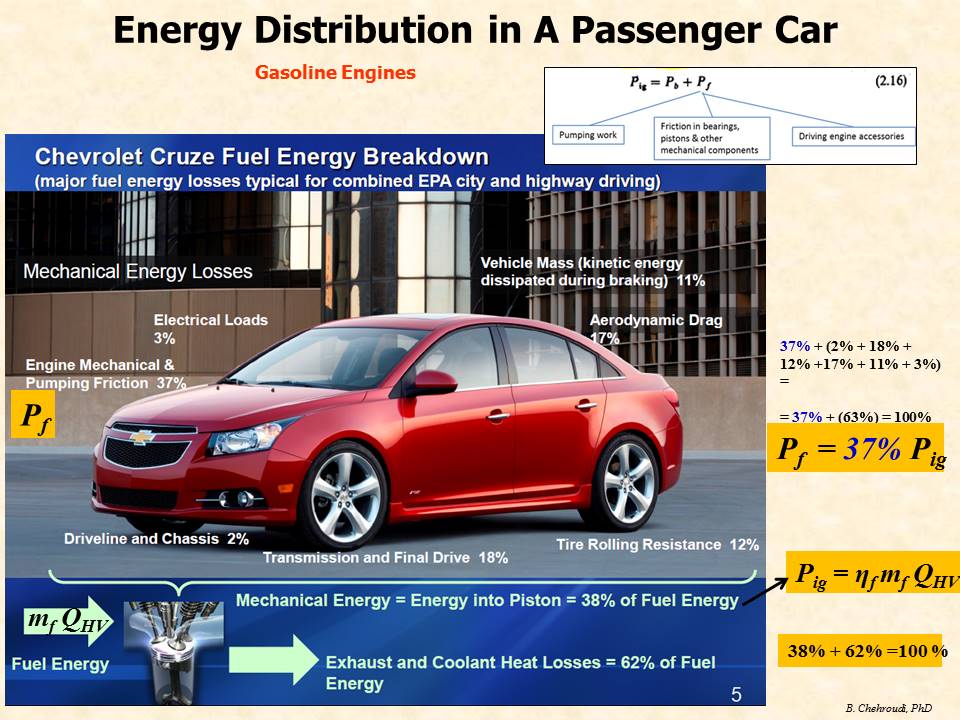

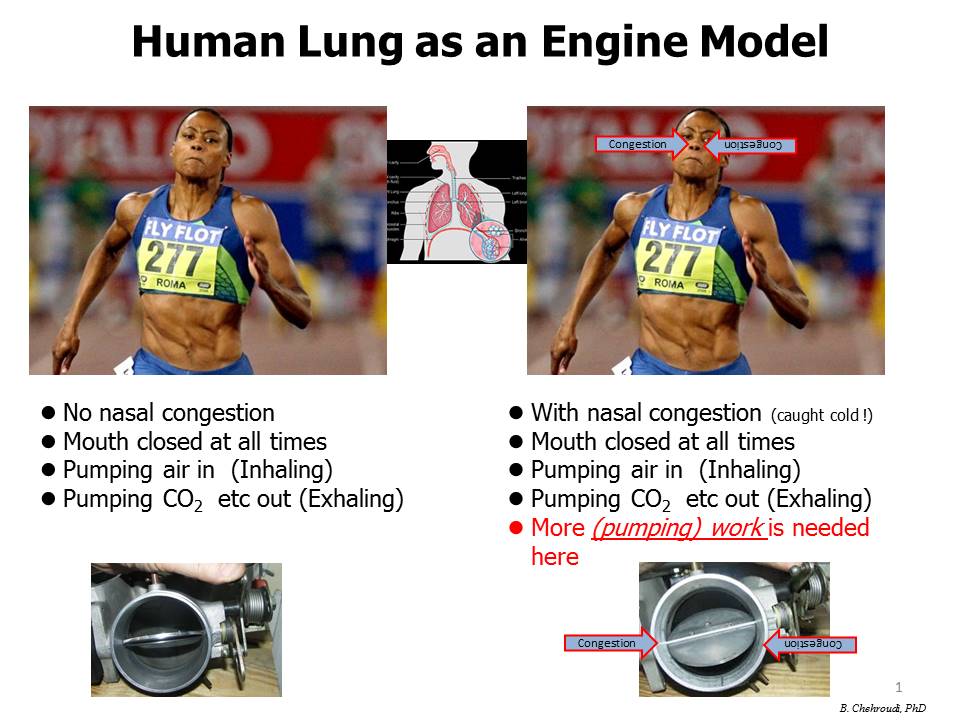

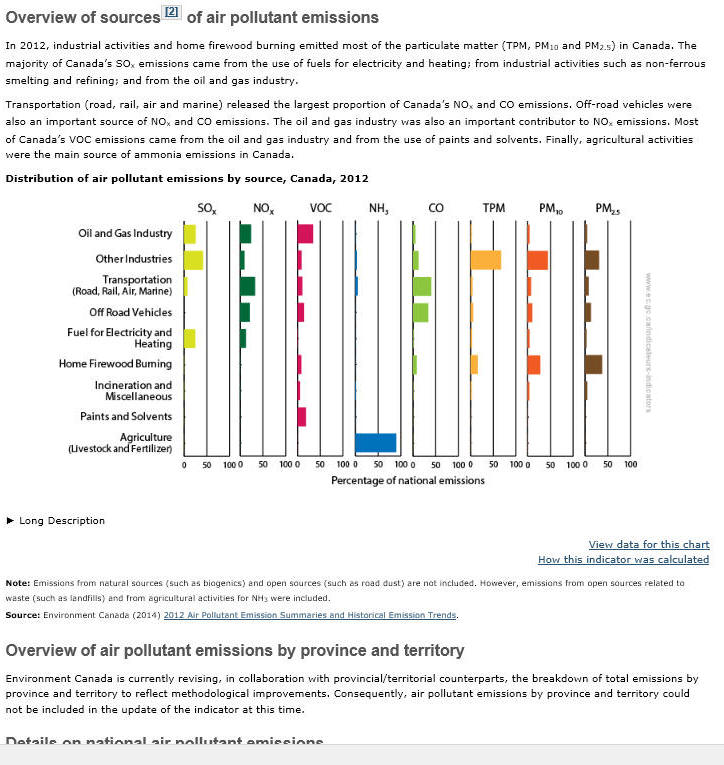

To simultaneously minimize the fuel consumption and the emission of

regulated pollutants from reciprocating automotive internal

combustion engines, the intensive R&D efforts in US on in-cylinder

combustion improvements have focused on the low-temperature gasoline

combustion (LTGC) or homogeneously-charges compression-ignition (HCCI)

engines, which are based on in-cylinder volumetric auto-ignition and

combustion of the fuel/air mixture. Research has shown promising

potentials of these engines for contributions towards the stringent

fuel economy regulations on the fleet-averaged fuel consumption

targets to be met both in US and in Europe. However, a

technologically and economically viable start-of- combustion control

(or controlled auto-ignition) has been the main barrier for such

advanced combustion engines. This proposal suggests an innovative,

nanotechnology-based very-low-input-energy optical approach to

address this important problem. Essentially, this is a synergy

between light, chemical reaction, and nanotechnology.

Statement of how this problem or

situation is being addressed:

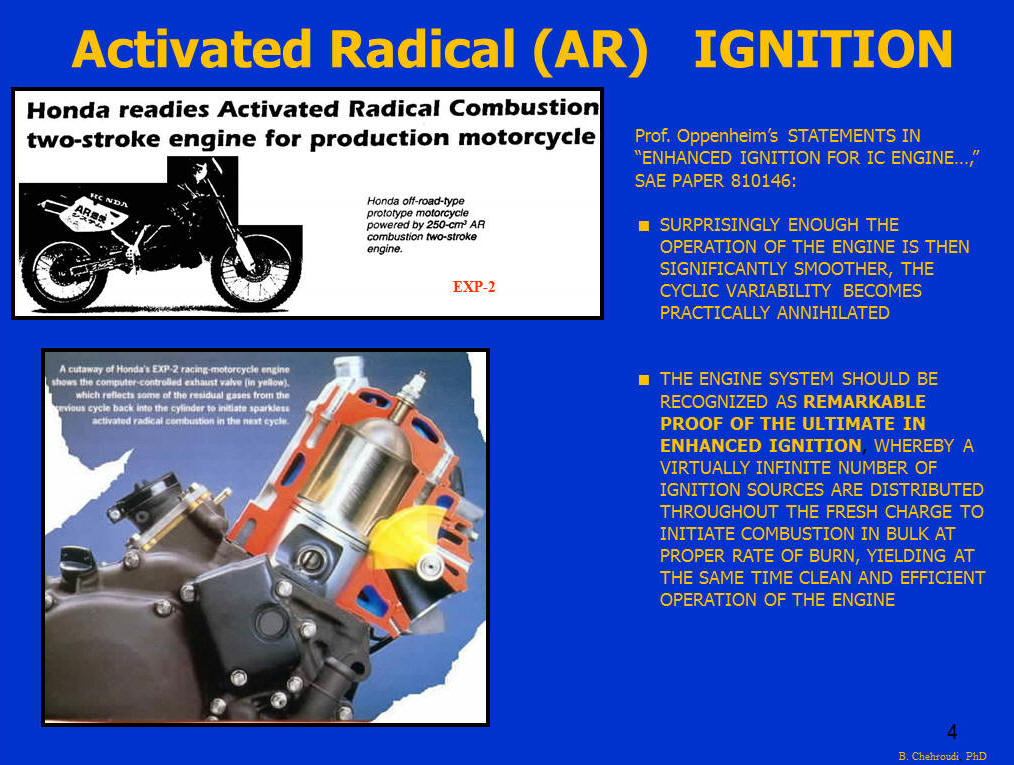

The

problem of precise control of the volumetric start-of-combustion in

each engine cycle (i.e., controlled auto-ignition) is addressed

through a serendipitously-found synergy between nanotechnology,

light energy, and chemical reaction. Specifically, a

sufficiently-large number of suitably-selected nanotechnology-based

ignition agents (IA) are mixed, as an additive, to the gasoline fuel

which are then fluidized upon full vaporization of in-cylinder

liquid fuel droplets to act as volumetrically-distributed ignition

sources. Upon exposure to a simple pulsed light source (such as an

ordinary low-energy camera flash), these in-cylinder

volumetrically-distributed nanostructured IAs are shown to ignite

(i.e., controlled auto-ignition) and lead to a volumetric combustion

of the fuel-air mixture. This innovative control of the start and

subsequent evolution of the volumetric combustion, addresses an

important technological barrier for the LTGC / HCCI engines.

Project

Objectives: While the

feasibility of the light-activated volumetrically-distributed (LAVD)

ignition under a lean gaseous fuel/air mixture in a constant-volume

combustion chamber has already been demonstrated, the main

objective of this proposed research is to demonstrate feasibility

and performance of the LAVD ignition method in a single-cylinder

4-stroke reciprocating internal combustion (IC) research engine at

Sandia Combustion Research Facility. Initial optical diagnostics

such as laser-induced fluorescence (LIF) and heat release analysis

should provide fundamental understanding on ignition and combustion

process.

Commercial applications and other

benefits:

This innovative ignition method removes

an important technological barrier towards development and

implementation of the environmentally cleanest, and simultaneously,

most efficient reciprocating internal combustion engine using fossil

fuels. The high efficiency of this engine addresses the economic

aspect of the public life and the positive environmental impacts

contribute towards the public health.

"Authority must be accompanied by

prestige and prestige comes only from distance."

By Charles De Gaulle [Le Fil de lepee,

1934]

____________________________________

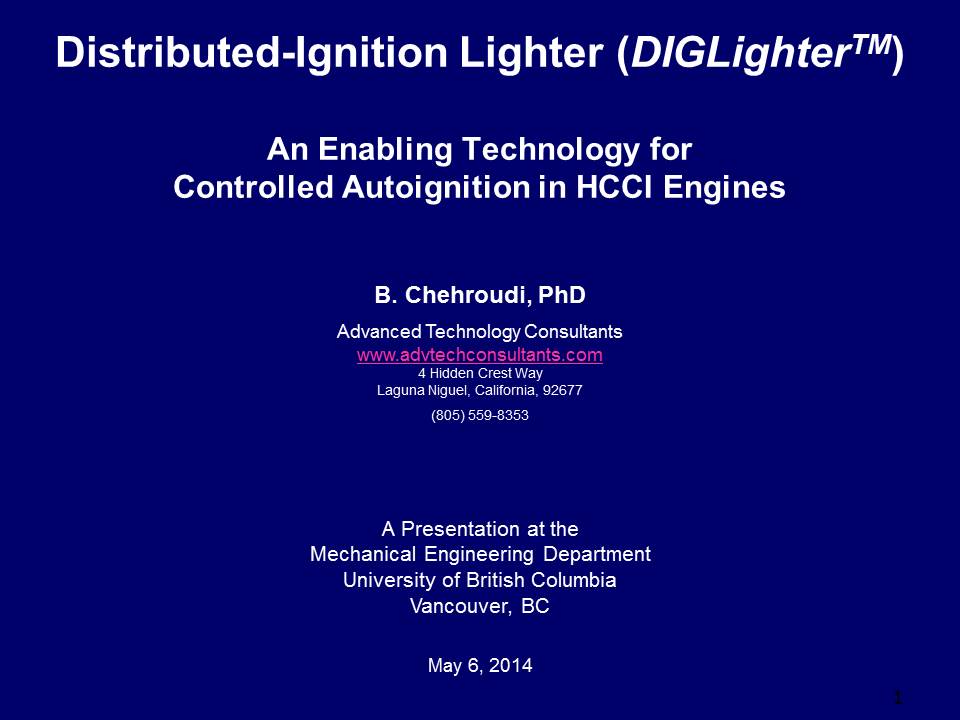

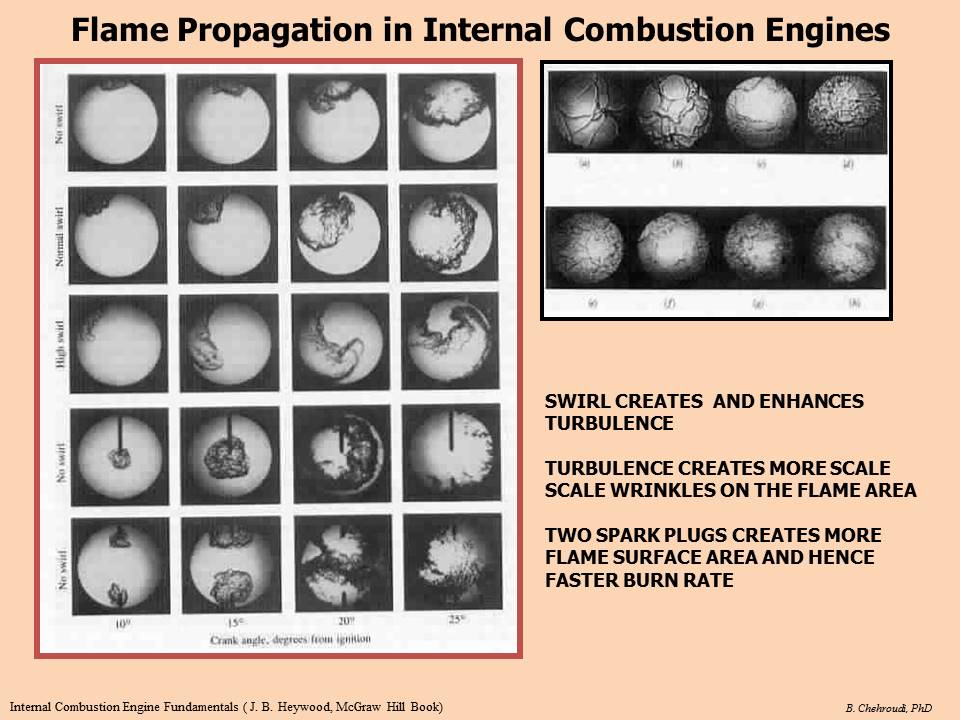

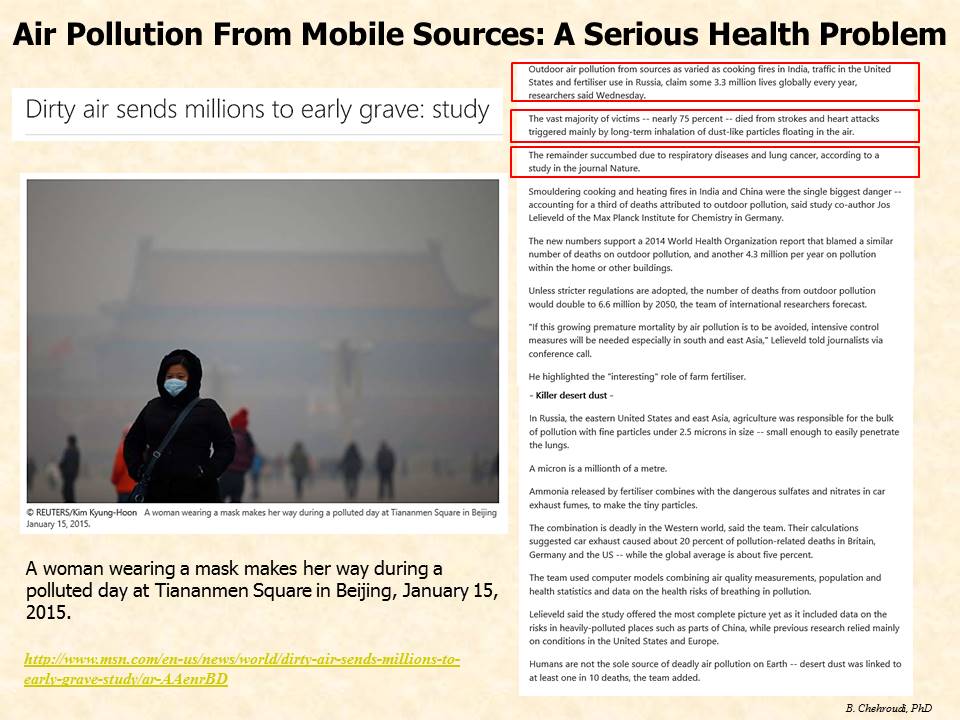

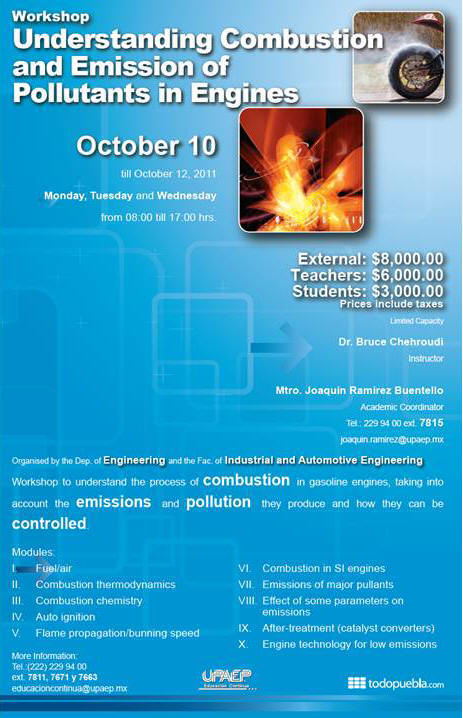

On May 14-16, 2018, Dr Chehroudi was

an invited speaker in Detroit, Michigan, by the society of

Automotive Engineers and presented series of lectures to

engineers, designers, researchers, R&D managers on combustion and

emission of pollutants from engines. Topics such as

low-temperature combustion, homogeneous-charged spark

ignition, HCCI, SpCCI, auto-ignition, knock, alternative

fuels, and key factors that affect fuel efficiency and

emission of regulated pollutants were amongst the topics discussed. managers on combustion and

emission of pollutants from engines. Topics such as

low-temperature combustion, homogeneous-charged spark

ignition, HCCI, SpCCI, auto-ignition, knock, alternative

fuels, and key factors that affect fuel efficiency and

emission of regulated pollutants were amongst the topics discussed.

Dr Chehroudi also also presented his patented

and ground-breaking work on Light-Activated

Volumetrically-Distributed ignition using nanostructured materials

for controlling autoignition in HCCI engines.

Attendees were from the following

organization:

PACCAR Inc

Intertek Carnot Emission Services

NGK Spark Plugs Inc

Kohler Co

Consumers Union of US Inc

(Consumer Report)

Toyota Motor Corp

Honda R&D America

____________________________________

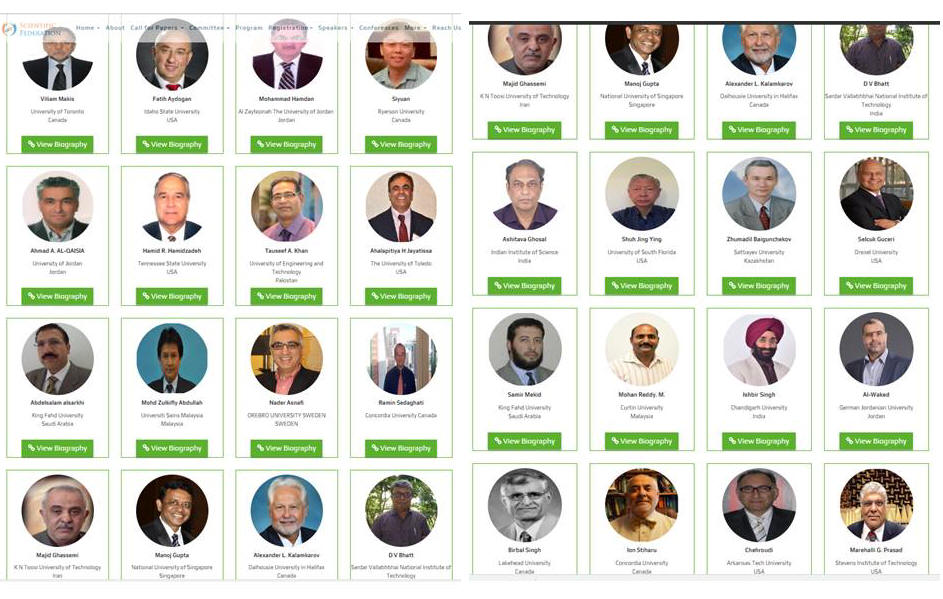

Dr Chehroudi is a member of the

Organizing Committee for the 2nd World Congress on

Mechanical and Mechatronics

Engineering to be held in Dubai, UAE, from April 15 to

17, 2019.

This conference is now an established

event, attracting global participant’s intent on sharing, exchanging

and exploring new avenues of Mechanical and Mechatronics Engineering

and related research and latest developments.

The event will have 5-6 world level

(Highly cited class) plenary speakers, established Keynote speakers,

active Invited speakers and fresh contributed speakers. In addition,

variety of poster presentations along with workshops and special

sessions would be interested in audience.to promote quality research

and real-world impact in an atmosphere of true international

cooperation between scientists

and engineers by bringing together again the world class

researchers, International Communities and Industrial heads to

discuss the latest developments and innovations

in the fields of Mechanical and Mechatronics Engineering.

____________________________________

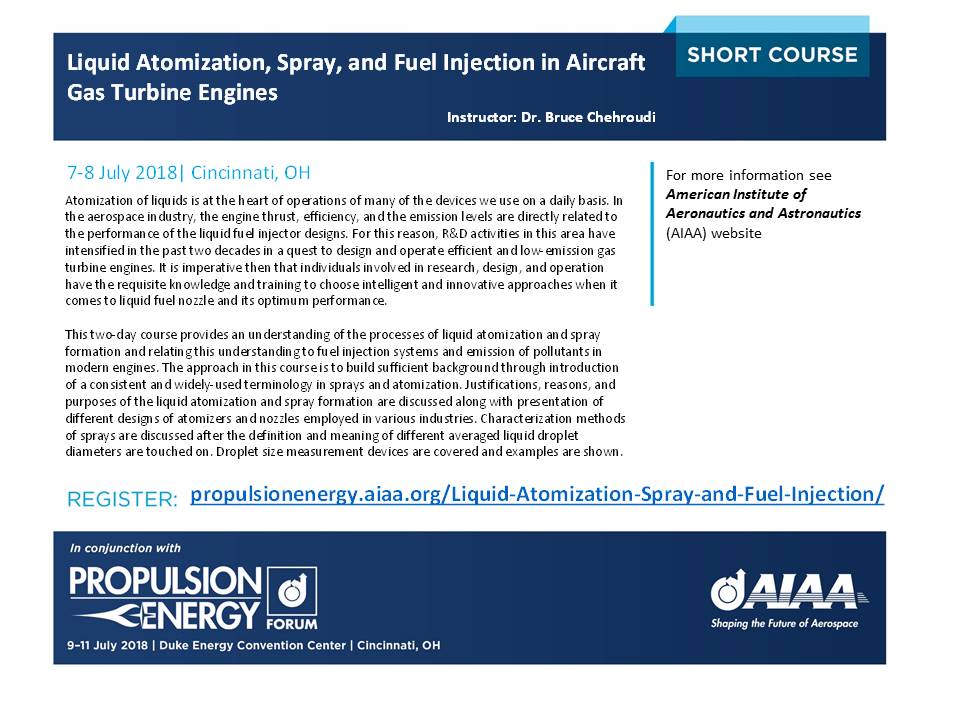

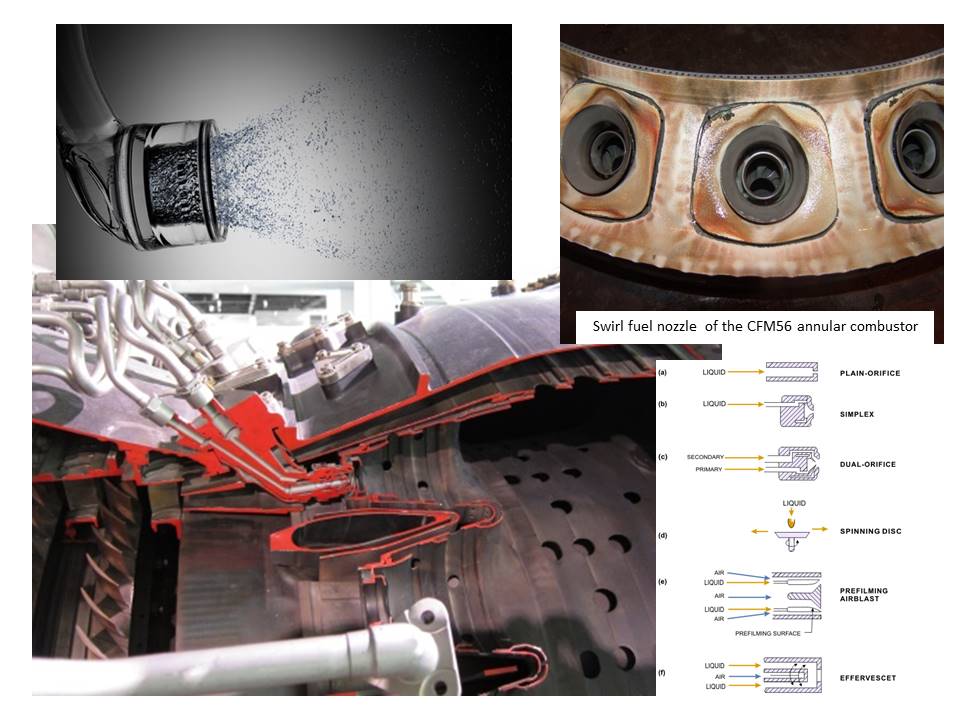

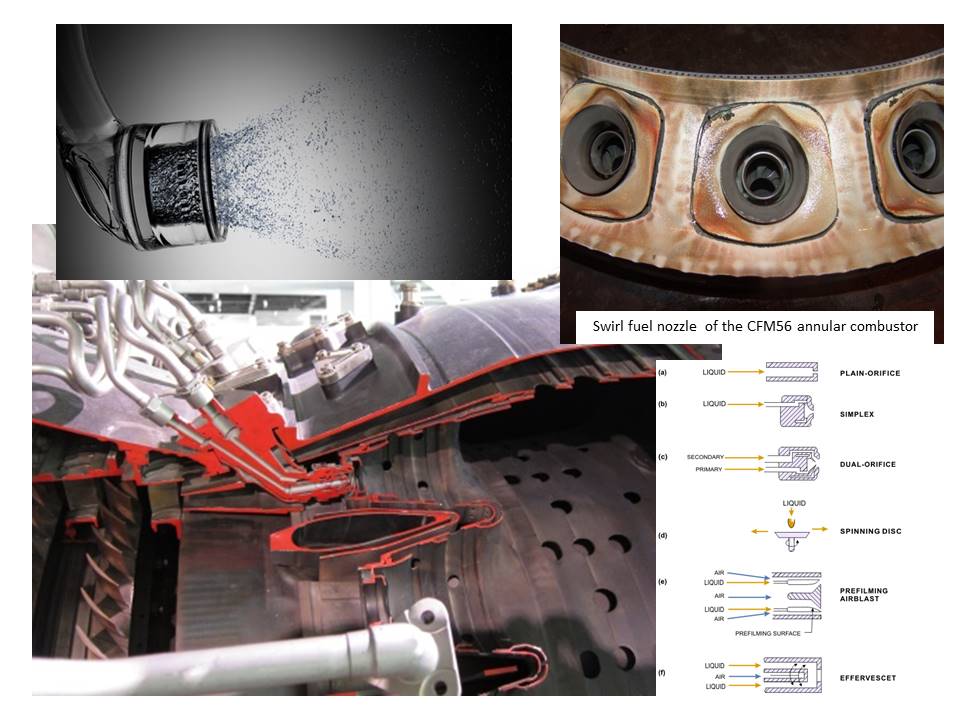

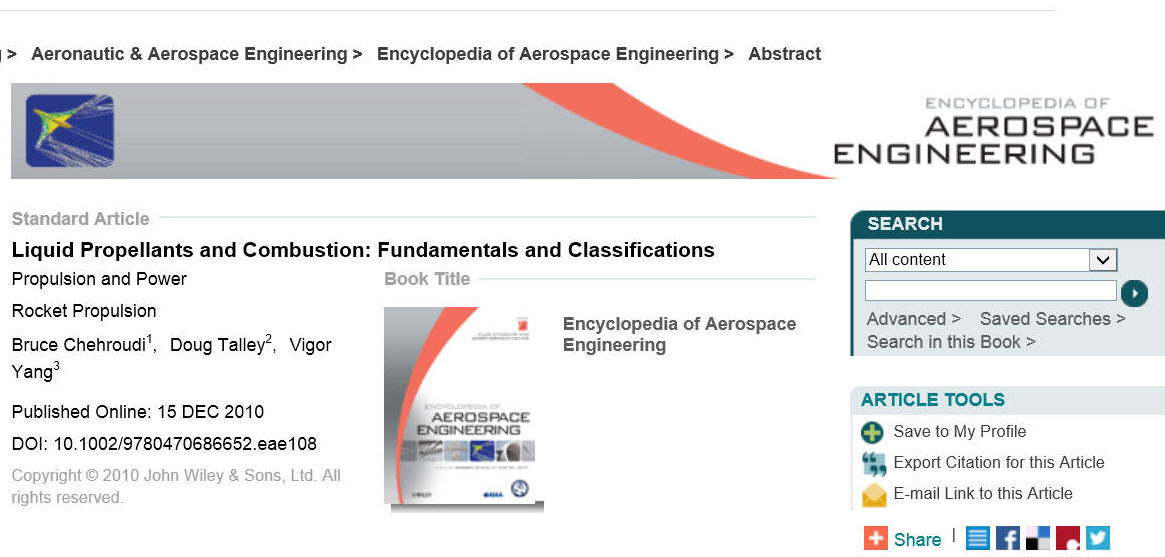

Dr. Chehroudi will be an

Invited Speaker to deliver a short seminar on Liquid

Atomization, Sprays, and Fuel Injection in Aircraft Gas Turbine

Engines. The seminar is sponsored by

the American Institute of Aeronautics and

Astronautics (AIAA) and will be held in Cincinnati, Ohio, July 7-8,

2018. Register at:

http:propulsionenergy.aiaa.org/Liquid-Atomization-Spray-and-Fuel-Injection/

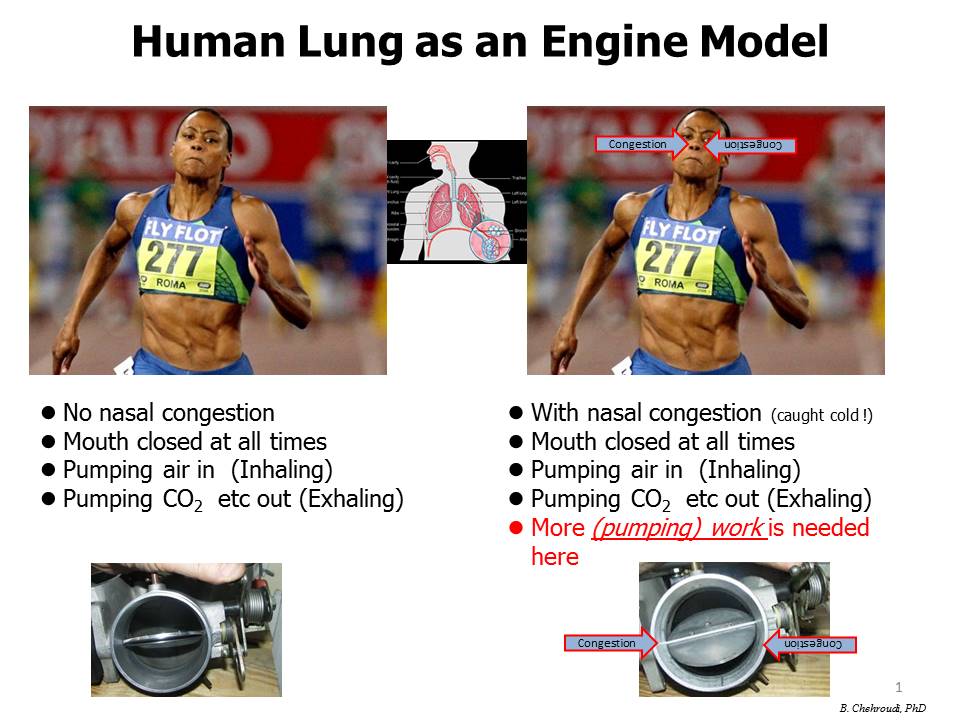

Atomization of liquids is at the heart of

operations of many of the devices we use on a daily basis. In the

aerospace industry, the engine thrust, efficiency, and the emission

levels are directly related to the performance of the liquid fuel

injector designs. For this reason, R&D activities in this area have

intensified in the past two decades in a quest to design and operate

efficient and low-emission gas turbine engines. It is imperative

then that individuals involved in research, design, and operation

have the requisite knowledge and training to choose intelligent and

innovative approaches when it comes to liquid fuel nozzle and its

optimum performance.

This two-day course provides an

understanding of the processes of liquid atomization and spray

formation and relating this understanding to fuel injection systems

and emission of pollutants in modern engines. The approach in this

course is to build sufficient background through introduction of a

consistent and widely-used terminology in sprays and atomization.

Justifications, reasons, and purposes of the liquid atomization and

spray formation are discussed along with presentation of different

designs of atomizers and nozzles employed in various industries.

Characterization methods of sprays are discussed after the

definition and meaning of different averaged liquid droplet

diameters are touched on. Droplet size measurement devices are

covered and examples are shown

Learning Objectives

-

Understand and be familiarized with

important terminology commonly used in atomization and sprays

-

Gain a general physical understanding of the important processes

in atomization and spray formation

-

Possess adequate background and foundation to educate yourself

beyond the depth and topics covered

-

Be able to intelligently judge, adapt, and transfer

technological advances from one discipline to the other

-

Understand effects of fuel nozzle design and operating

conditions on engine performance, combustion, and emission of

pollutants

-

Be able to communicate intelligently with engineers working on

fuel nozzle and fuel system design aspects in your company

-

Grasp the technology and the logic behind different injector

designs

-

Gain sufficient knowledge to intelligently contribute to humans'

efforts in minimizing emission of pollutants and maximizing

efficient usage of Earth's energy resources

-

Anticipate future trends and technology developments in fuel

nozzles

-

Learn and appreciate the role the fuel nozzle plays in

combustion and emission and how it is used to provide guidance

in design of low-emission combustion systems

-

Effectively contribute to the design of the critical engine

components affected by the fuel nozzle performance

Who Should Attend

Engineers working on the design of

components for high efficiency and performance of combustion

engines, particularly those directly and indirectly involved in

reducing emission of harmful pollutants from combustion engines,

will highly benefit from this course. Additionally, this course

provides adequate background for engineers and managers in contact

with those directly involved in the fuel nozzle systems. Therefore,

this experience prepares the attendees for a more efficient and

intelligent communication in an interdisciplinary technological

environment. The course is also of interest to academicians wishing

exposure to the field and those engineers active in development and

applications of software, modeling in-cylinder injection combustion

and emission processes.

Outline

Day 1

-

Description of the atomization

process

-

Disintegration of the liquid jets

-

Disintegration of liquid sheets

-

Drop breakup in air flow, turbulent flow, and viscous flow

-

Types of atomizers and their design features

-

Spray drop size distribution and measurements

-

Drop and spray evaporation

Day 2

-

Fuel spray in the combustor confines

-

Spray flame in gas turbine combustors

-

Spray flame stabilization

-

Effects of fuel nozzle design and operating parameters on spray

characteristics and combustor performance

-

Effects of fuel nozzle design and operating parameters on

emission of pollutants

-

Matching of fuel spray with the combustor

-

Fuel nozzles for lean direct injection

-

Advanced concepts

____________________________________

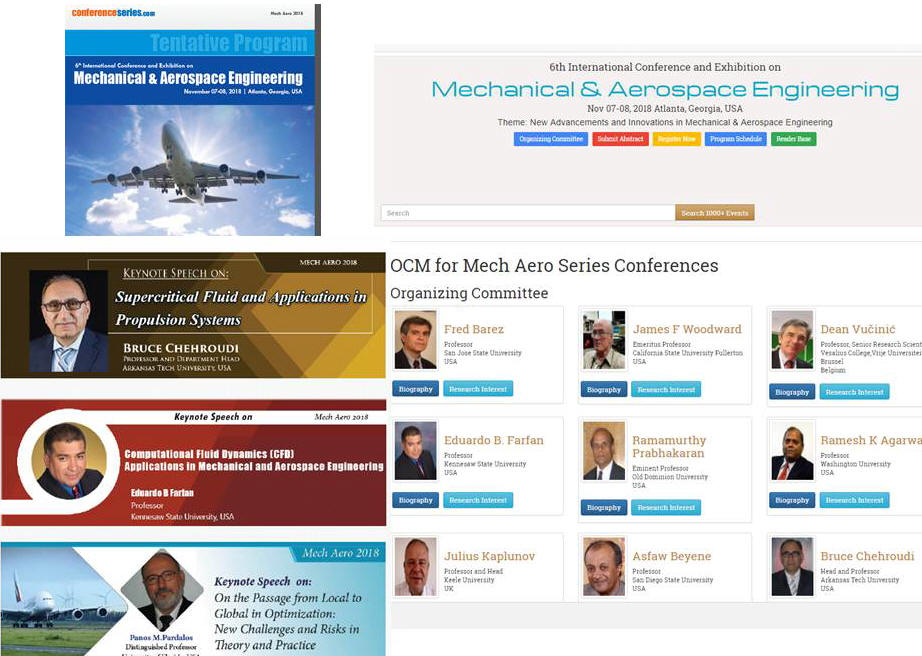

Dr. Chehroudi will be a

member of the Organizing Committee and a

Keynote Speaker at the Mech Aero 2018 Conference in

Atlanta, Georgia (Nov 7-8, 2018). Dr Chehroudi will be giving a

presentation titled "Supercritical Fluid and Applications in

Propulsion Systems".

The theme in this conference will be

New Advanced & Innovations in Mechanical and Aerospace Engineering

Click for

Tentative schedule

____________________________________

Dr. B. Chehroudi is a

member of the Organizing Committee of the 2018

Asia Conference on Mechanical Engineering and Aerospace Engineering

(MEAE2018). The conference will be held during the June

23-25, 2018 at China University of Geosciences (Wuhan) in Wuhan,

China. The MEAE 2018 will be an internationally renowned forum

for researchers, practitioners, and educators to present and discuss

the most innovations, trends, experiences, and challenges in the

fields of Mechanical Engineering and Aerospace Engineering. It will

bring together experts from academia and industry to exchange the

latest research results and trends, and their practical applications

in the aforementioned areas of Mechanical Engineering and Aerospace

Engineering. This will be accomplished through the following three

modes of communications: Keynote presentations, Parallel sessions,

and poster sessions.

Advisory Committees

Prof. Ji Wu, National Space Science Center

,Chinese Academy of Sciences, China

General Conference Chair

Prof. Huafeng Ding, China University of Geosciences, China

Conference Committee Chair

Prof. Dan Zhang, York University, Canada

Program Chairs

Prof. Chiharu ISHII, Hosei University, Japan

Assoc. Prof. Tzong-Hann Shieh, Feng Chia University, Taiwan

Technical Committees

Assoc. Prof. Rosli Bin Ahmad, Universiti Tun

Hussein Onn Malaysia, Malaysia

D. Ramasamy, Faculty of Mechanical Engineering, Universiti Malaysia

Pahang, 26600 Pekan, Pahang, Malaysia

Assoc. Prof. Chong Wen Tong, University of Malaya, Malaysia

Assoc. Prof. Ahmad Yusairi Bani Hashim, Universiti Teknikal Malaysia

Melaka, Malaysia

Dr. Mainul Islam, University of Southern Queensland, Australia

Prof. Md Alamgir Hossain, Department of Mechanical Engineering,

Military Institute of Science and Technology, Bangladesh

Lecturer Baojian Yang,Wuyi

University,China

Prof. Fred Barez, San Jose State University, USA

Prof. Bruce Chehroudi, Arkansas Tech University USA

Dr. Javaid Butt, Anglia Ruskin University, UK

Prof. Sümer Şahin, Near East University, Turkey

Assoc.Prof. Mehdi Hojjati, Concordia

University, Canada

Assoc.Prof. Sunny Joseph Kalayathankal, K. E. College, Mannanam,

Kottayam, India

Prof. Ramamurthy Prabhakaran,Old

Dominion University USA

____________________________________

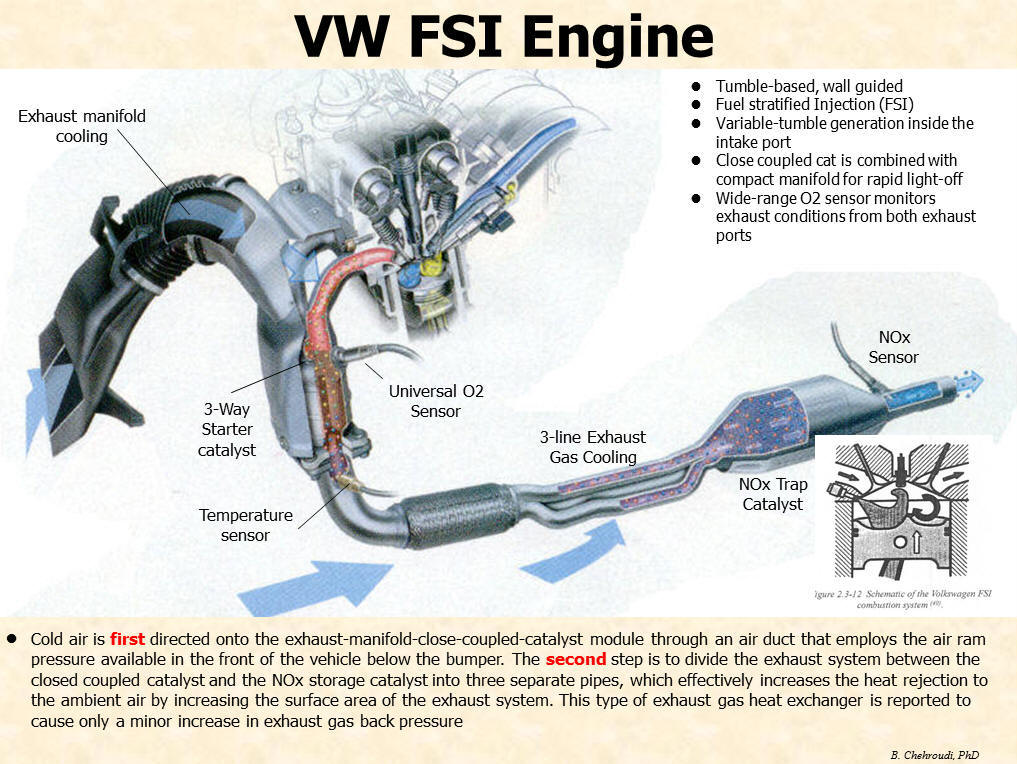

On Monday, Dcember 18-20, 2017, Dr. Chehroudi has delivered a 3-day seminar on

Combustion and

Emission of Pollutants from Automotive Engines at the Society

of Automotive Engineers facility in Troy, Michigan. Thorough

and in-depth understanding of the thermodynamics, gas dynamics, and

combustion chemistry is at the heart of the intelligent approach towards

control of the engine combustion and emission of pollutants. To this

end, Dr. Chehroudi's seminar covers key aspects of the combustion of

the fuel air mixtures for best fuel economy at the lowest emission of

the harmful/regulated pollutants. dynamics, and

combustion chemistry is at the heart of the intelligent approach towards

control of the engine combustion and emission of pollutants. To this

end, Dr. Chehroudi's seminar covers key aspects of the combustion of

the fuel air mixtures for best fuel economy at the lowest emission of

the harmful/regulated pollutants.

Representatives from the following

organizations attended the seminar:

_ Volkswagen

_ Toyota Technical Center USA, Inc.

_ Hundai

_ NGK

_ JohnDeere

____________________________________

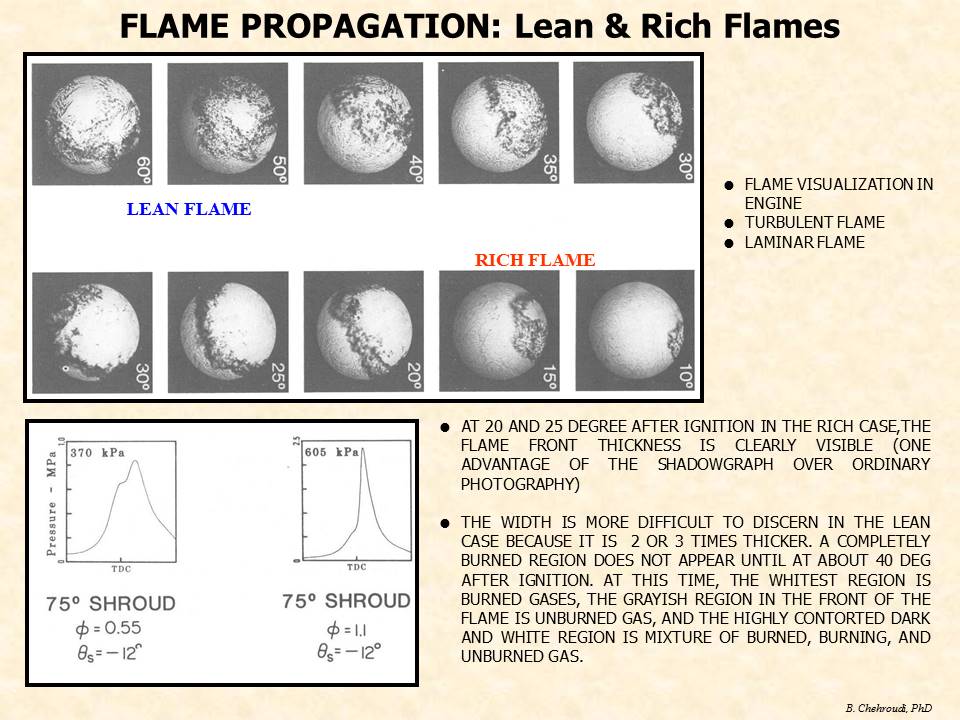

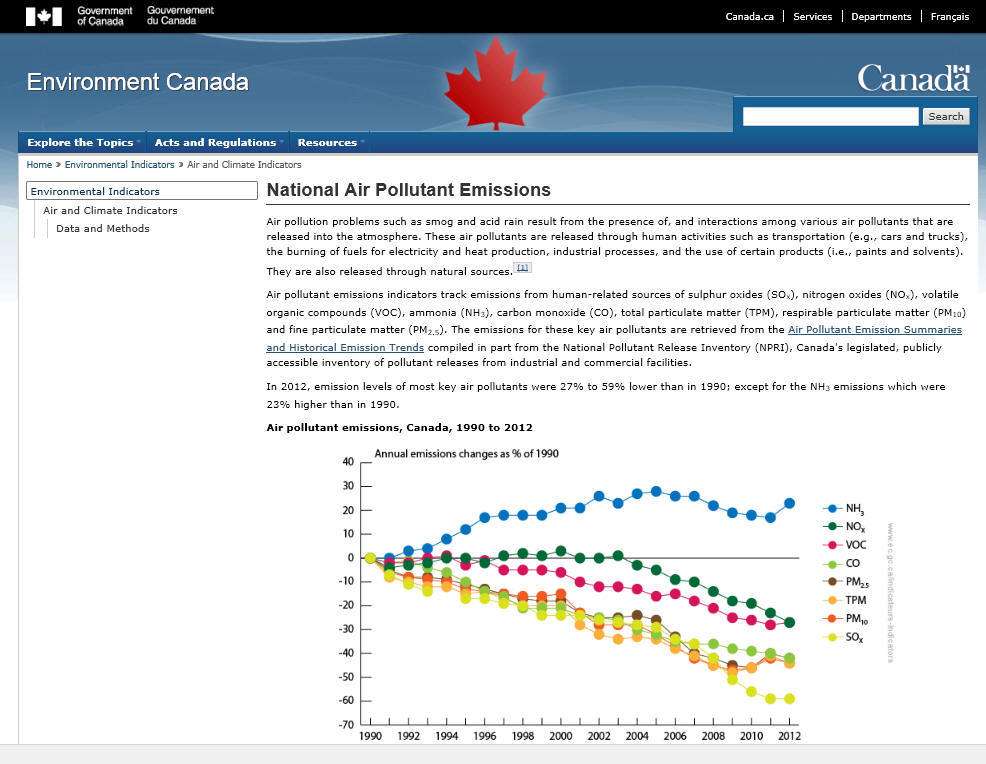

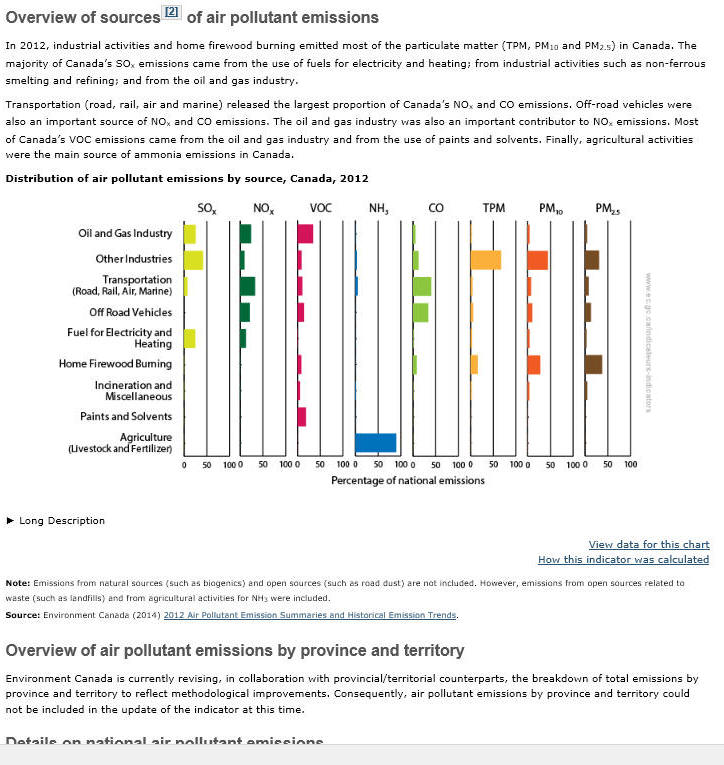

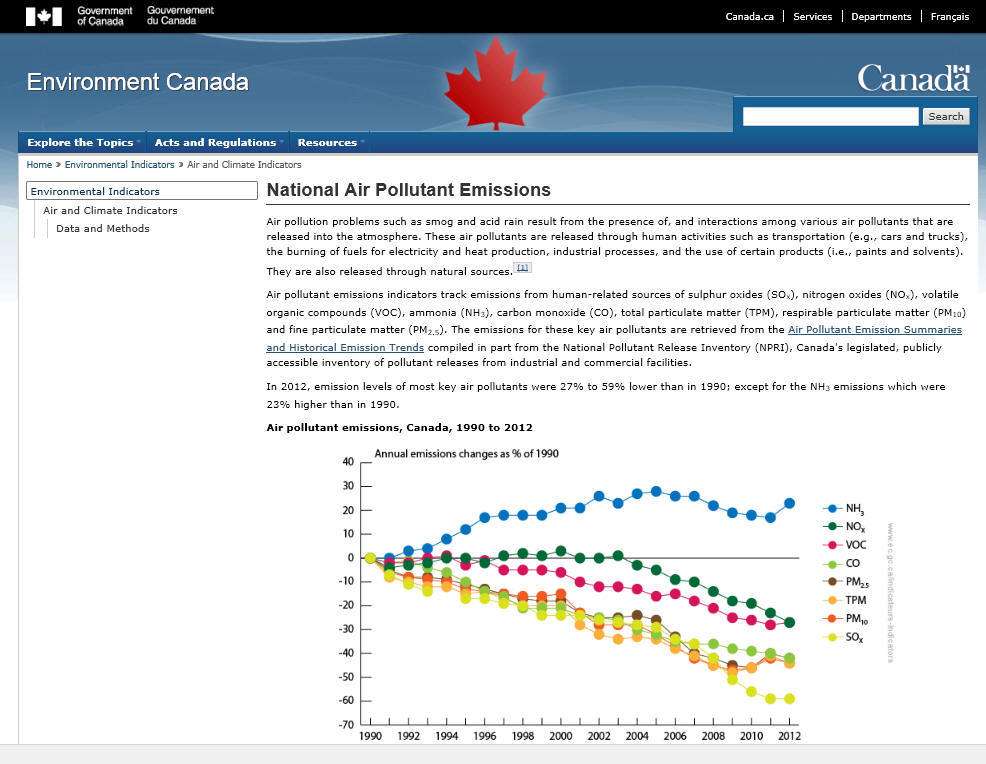

On Tuesday, November 22, 2017, Dr. Chehroudi was invited to

Environment Canada,

Quebec, to conduct a three-day

presentation. Dr. Chehroudi has presented his views on the

combustion in gasoline-fueled IC Engines and emission of pollutants combustion efficiency, emission of pollutants, and

performance of automotive engines. Below is a partial list of

topics discussed during the presentation. Presentation was followed

by a consulting session exploring areas of mutual interest and

future collaboration.

-Distillation curve for fuels and its

importance

-Distinction between "overall" A/F and cylinder-based, or local A/F

-Black-box operation of the "oxygen sensor" and its purposes

-Equivalence ratio and "lambda"

-Adiabatic flame temperature and its physical meaning/importance

-Heating value

-Combustion efficiency

-Equilibrium and chemical kinetics

-Concept of "mechanism" of overall reaction

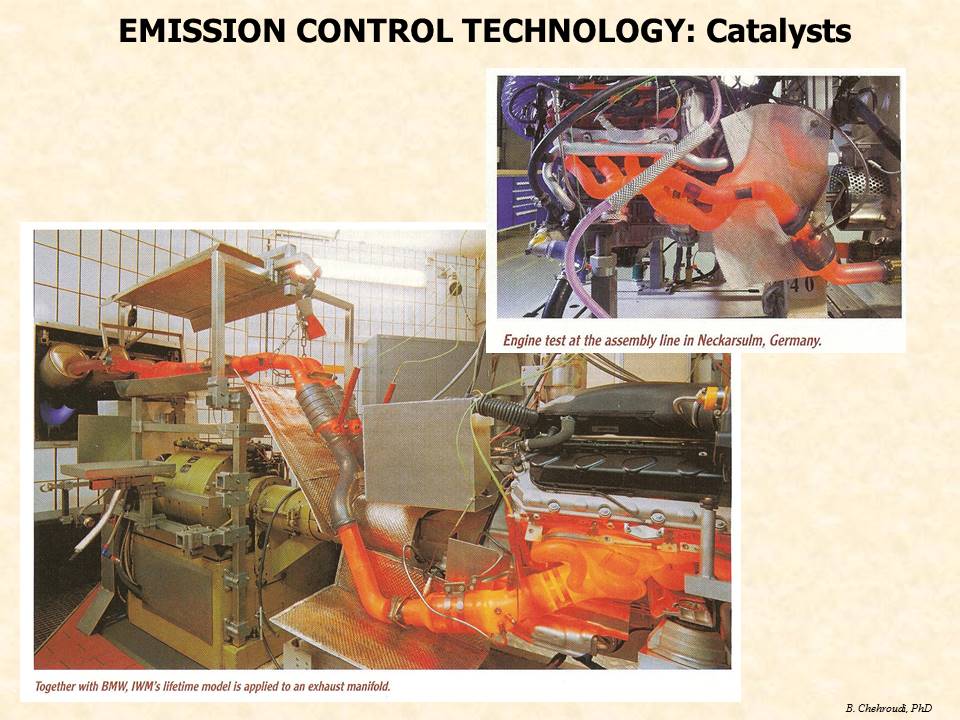

-The nature of (heterogeneous) catalytic reaction on surfaces

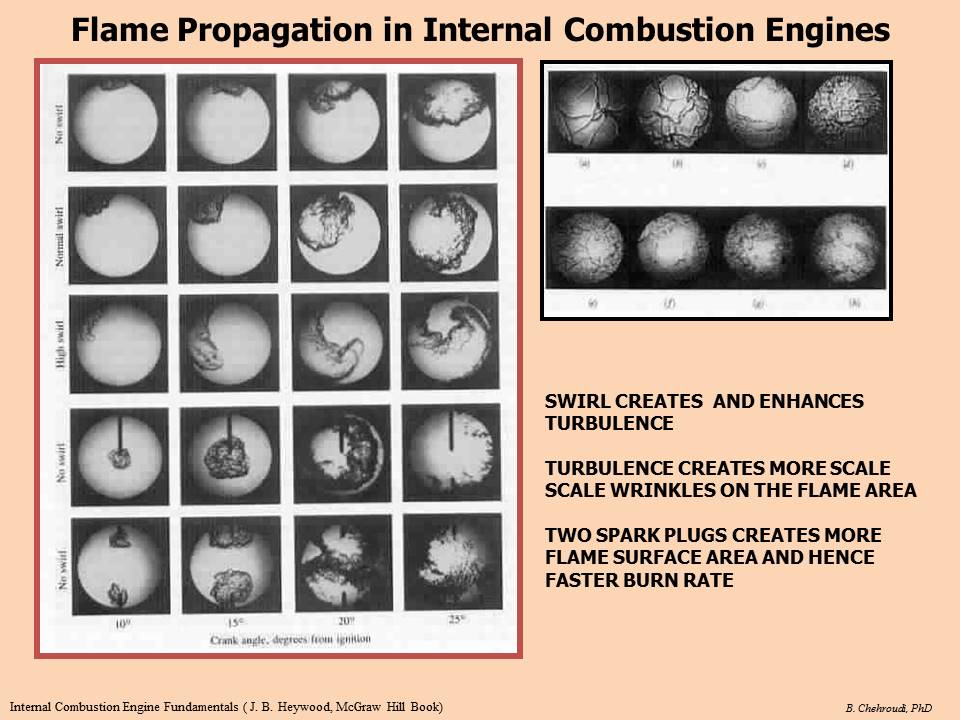

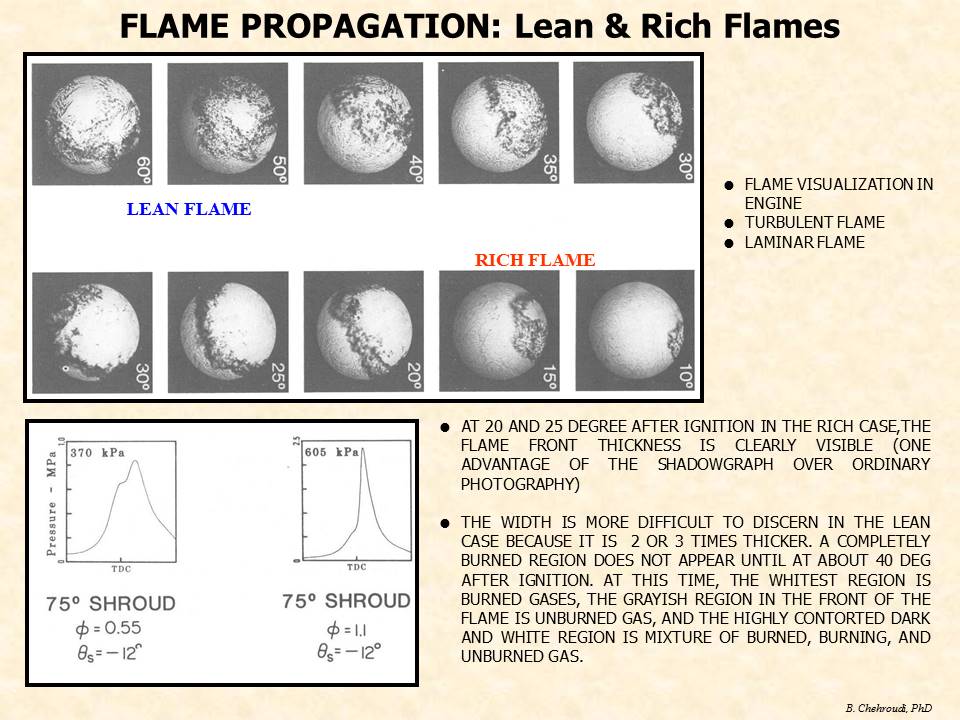

-Flame propagation

-Laminar burning speed

-Effects of turbulence on flame propagation

-Effects of residual burned gases (or EGR) on Flame propagation

-Impact of multiple spark plugs on flame propagation

-Cylinder pressure measurements and its behavior

-Effects of spark timing (advance/retard) on cylinder pressure

-Mass fraction burned curve & heat release analysis

-Autoignition and Knock in SI engines

-Physical meaning of "specific heat"

-Cyclic variability and how it is quantified

____________________________________

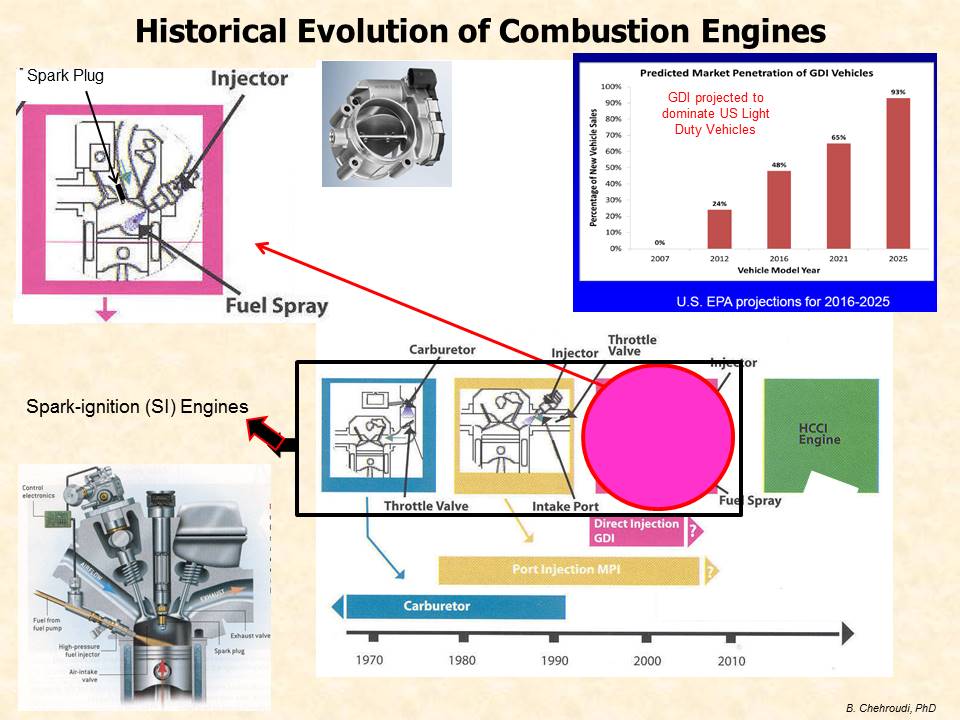

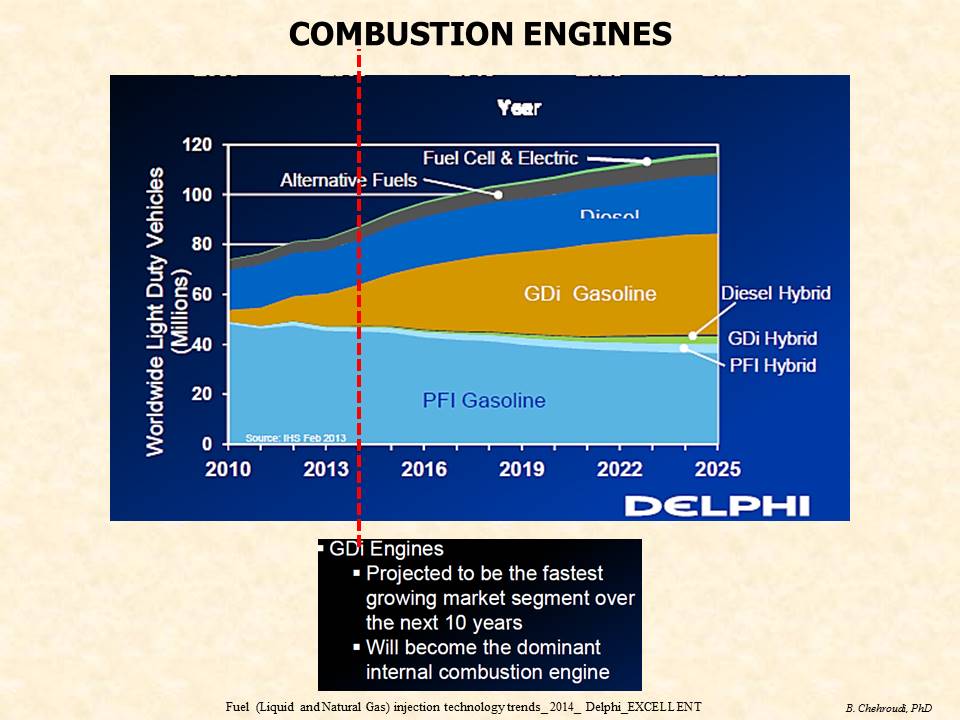

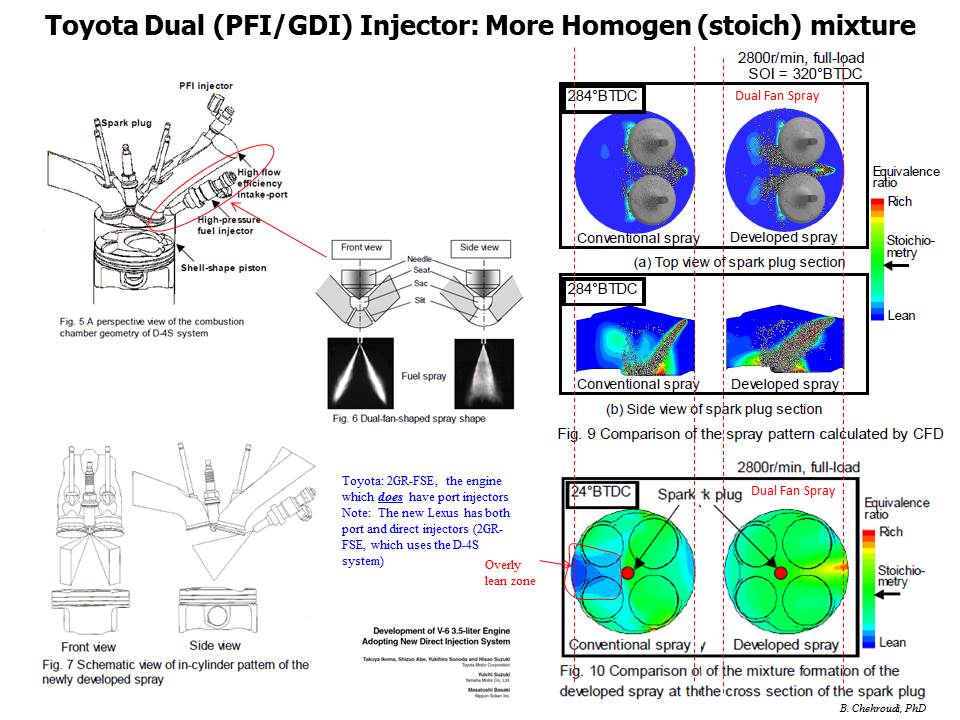

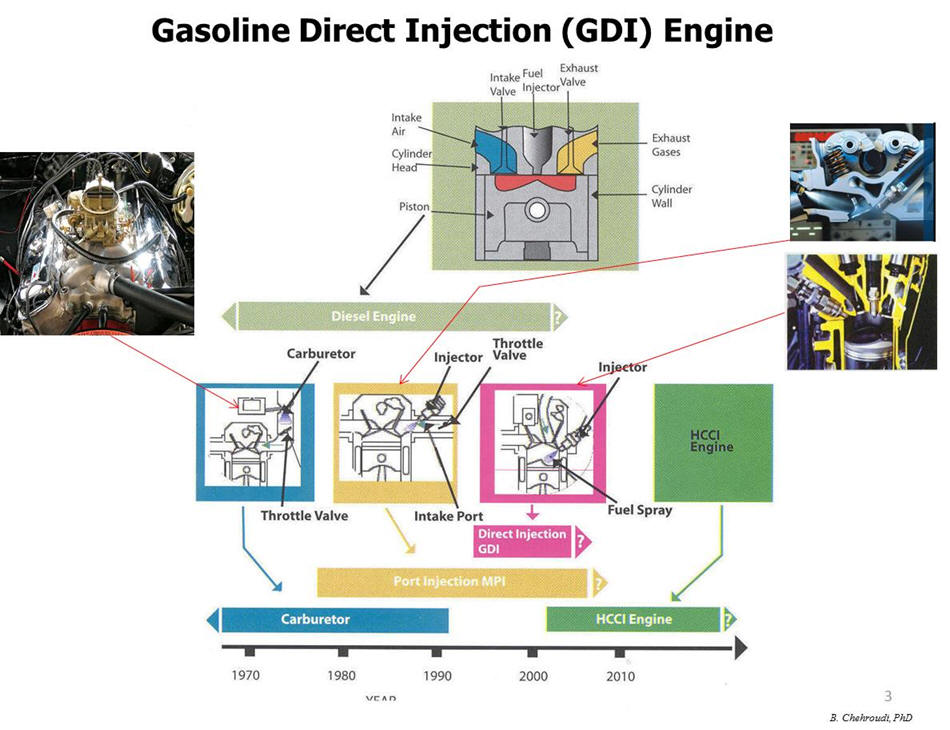

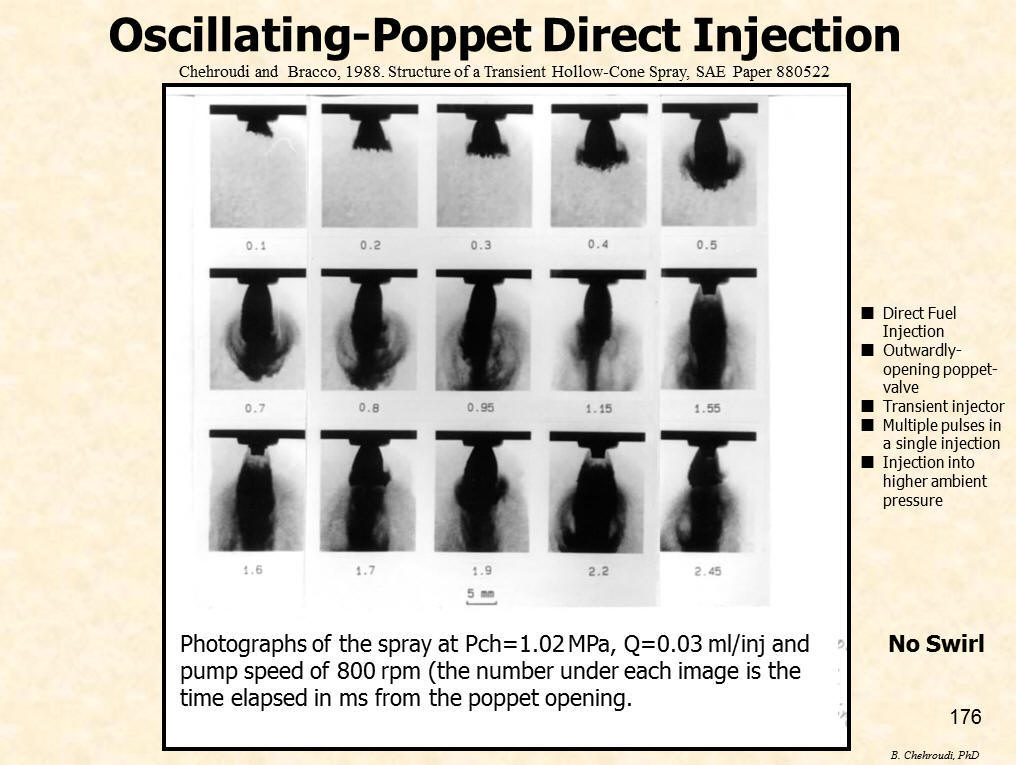

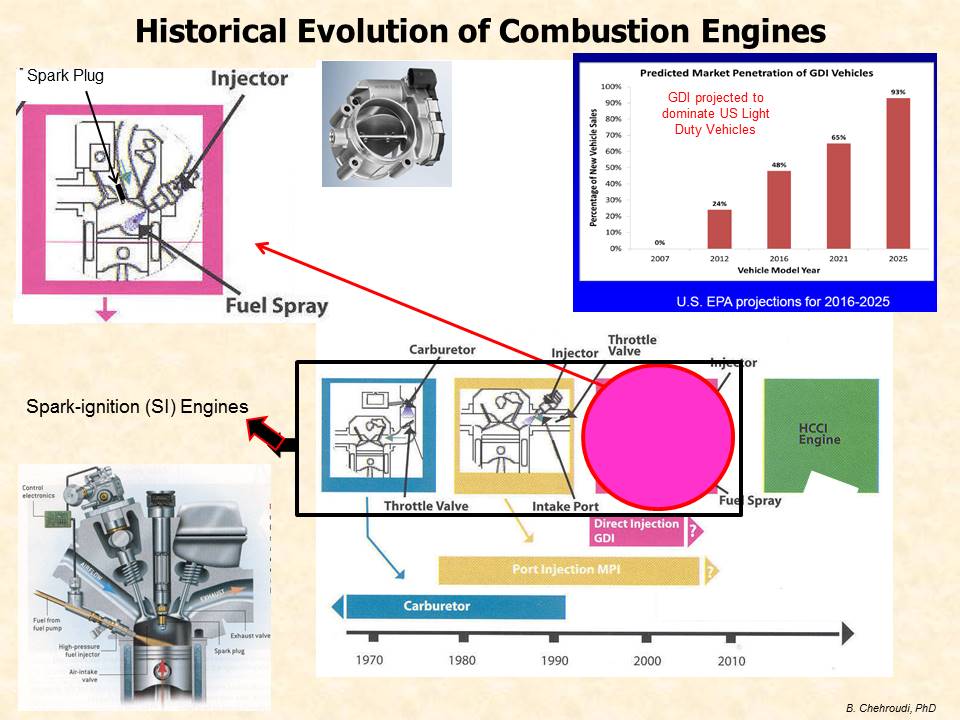

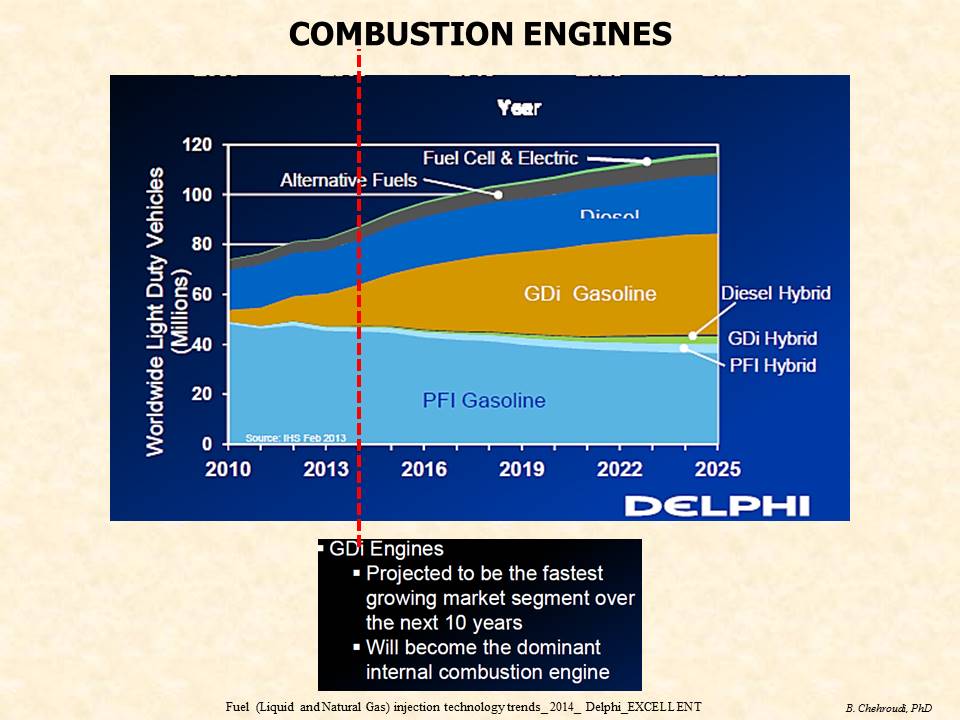

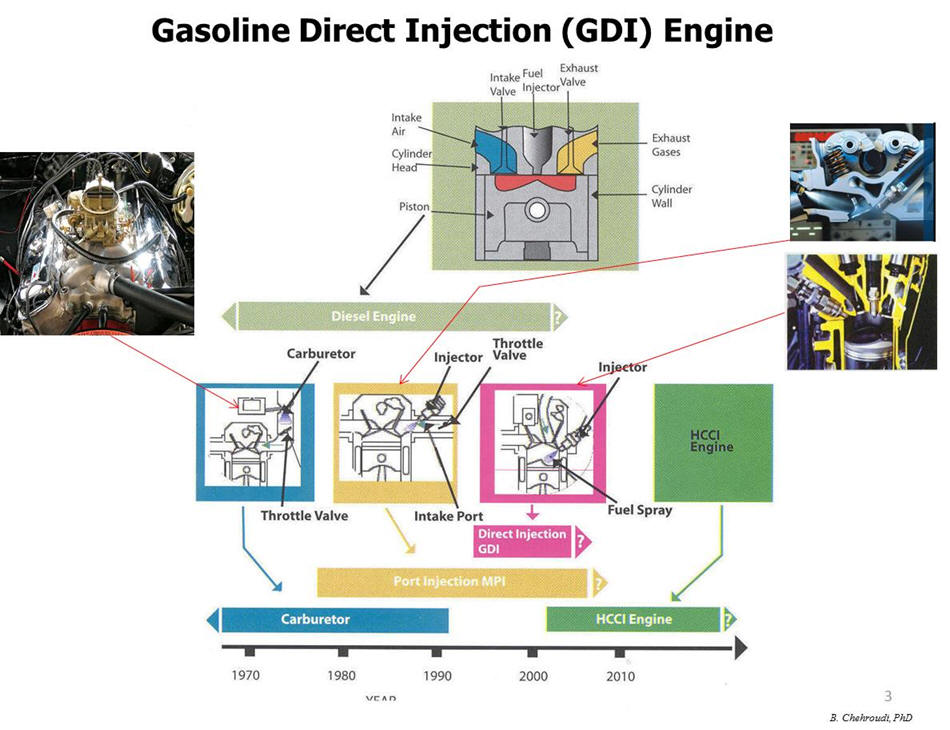

Dr Chehroudi was invited to

conduct a 3-day seminar on in-cylinder processes (liquid

atomization, vaporization, mixing, liquid spray-flow interactions,

chemically reactive flows, flame-turbulence interactions, pollutants

formations, etc) in Gasoline Direct Injection (GDI) engines that

affect efficiency, performance and tailpipe emission of pollutants.

The GDI engine is projected to be the fastest growing market in the

next 10 years and will become the dominant internal combustion

engine by 2025. EPA's 2025 projection of the fuel economy is at the

54.5 mpg level. Downsizing and turbocharging is one approach towards

this level of fuel economy along with host of other combustion

strategies such as stratified charge operation (Sept 11-13, 2017).

____________________________________

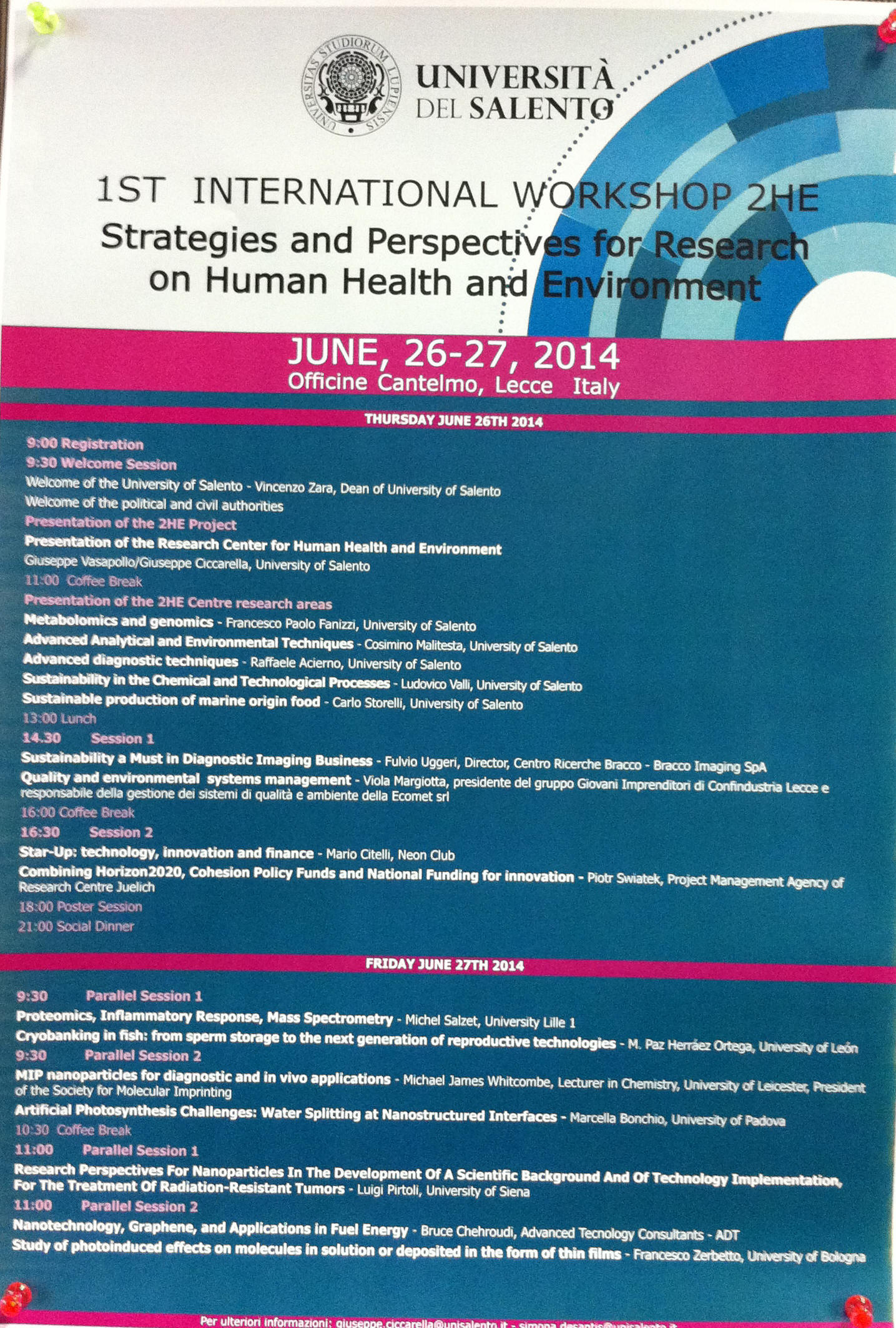

Dr. Chehroudi and his

collaborators (Professors A. P. Carlucci, A. Ficarella, D. Laforgia,

and researcher L. Strafella) from the University of Salento were

invited to contribute a chapter in a book titled "Carbon Nanotubes -

Recent Progress". The book is edited by M. M. Rahman and A. M.

Asiri (ISBN 978-953-51-5707-6). The chapter title is "Potential

Application of Photo-Thermal Volumetric Ignition of Carbon Nanotubes

in Internal Combustion Engines". It will be published in INTECH Open

Science / Open Minds (https://www.intechopen.com/ ). Other topics

covered in the book are Nanocomposites, Carbon, Chiral, Charcoal,

Carbon based sensors, Nanotubes, Conductors, Metallic tubes, Nano-structural

materials, Fibers, Carbon related material, Electrochemistry,

Catalysis, Mechanical property, Nanowires, Composites, Percolation,

Mediators, 3D materials, Modelling, Energy conversion, Splitting,

3rd generation, Solar cells, Supercapacitor, Fabrication, Nanocarbon,

Graphitic carbon, Core-shell study, Nanotechnology, Electronic

properly, Conductivity, Nanobuds, Peapod, Silicon (Aug 27, 2017).

_______________________________________________

Dr. Chehroudi has been

collaborating with professors and researchers at the

Department of

Innovation Engineering, University of Salento, Italy, which

led to a recent acceptance of a publication in the Journal of Fuels

(Elsevier) in a special Volume for Dual-Fuel and Fuel Additives

(coming soon). The work is quite unique, further demonstrating original and pioneering work by Dr

Chehroudi in applications of nano-structured materials for ignition

and combustion of fuels to achieve light-activated Volumetric

ignition of fuel-air mixtures, especially under lean conditions.

Collaborators were Prof. Antonio Ficarella,

Prof. Antonio Paolo Carlucci,

Prof. Domenico Laforgia (former President of the University of

Salento), and the PhD Student Dr. Luciano Strafella who did an

excellent job in such a difficult research work.

http://www.sciencedirect.com/science/article/pii/S0016236117309079#!

(July 12, 2017)

unique, further demonstrating original and pioneering work by Dr

Chehroudi in applications of nano-structured materials for ignition

and combustion of fuels to achieve light-activated Volumetric

ignition of fuel-air mixtures, especially under lean conditions.

Collaborators were Prof. Antonio Ficarella,

Prof. Antonio Paolo Carlucci,

Prof. Domenico Laforgia (former President of the University of

Salento), and the PhD Student Dr. Luciano Strafella who did an

excellent job in such a difficult research work.

http://www.sciencedirect.com/science/article/pii/S0016236117309079#!

(July 12, 2017)

Multi-Walled Carbon Nanotubes (MWCNTs)

Bonded with Ferrocene Particles as Ignition Agents for Air-Fuel

Mixtures

Abstract:

The potentials and characteristics of

a new ignition system for air-fuel mixtures are discussed. This

ignition method (referred to as photo-thermal ignition) is based on

light exposure of Multi-Walled Carbon Nanotubes (MWCNTs), bonded

with other nano-Structured Materials (nSMs), (collectively referred

here as “nanoignition agent”), using a low-consumption camera flash.

Here, ferrocene, an organometallic compound, was used as the nSMs.

Results from, and benefits of, this new ignition method are compared

with a conventional spark-plug-initiated ignition used in automotive

engines.

The main objective of this research

is to demonstrate ignition feasibility of mixtures of both gaseous

and liquid fuels with air under high pressures using the

photo-thermal ignition (PTI) phenomenon. Specifically, the ignition

and subsequent combustion characteristics of gaseous air-fuel

mixtures at different air-fuel ratios were investigated by means of

light exposures of nano-ignition agents (nIAs) after they are mixed

with air-fuel mixtures.

Analysis of the acquired data showed

that for the range of air-fuel ratios tested, the photo-thermal

ignition with a flash lamp resulted in a higher peak chamber

pressure when compared to those obtained with a conventional spark

ignition system. Heat release rate analysis showed that shorter

ignition delays and total combustion durations for the Photo-thermal

ignition are achieved. Comparative percent reduction of these values

for photo-ignition ranges from 20% to 50% for LPG and methane,

whereas values up to 70% were observed for the hydrogen. The

positive impact of the photo-thermal ignition appears to be

primarily at the ignition delay period of the combustion. With

liquid fuels, photo-thermal ignition was capable to ignite mixtures

as lean as a relative air-fuel ratio of 2.7 while the spark ignition

was incapable to initiate combustion. Additionally, tests with the

liquid gasoline injection highlighted that the combustion process

with a higher “residence mixing time” exhibited higher peak

pressures and shorter ignition delay times.

High-speed camera images were used to

capture images of the light emission during the combustion process

in visible range, allowing investigation of the ignition processes.

In particular, the results showed that the photo-thermal ignition

process of the air-fuel mixtures with nano-ignition agents led to a

spatially-distributed ignition followed by a faster consumption of

the air-fuel mixture with no evidence of any discernible flame front

formation or propagation.

_______________________________________________

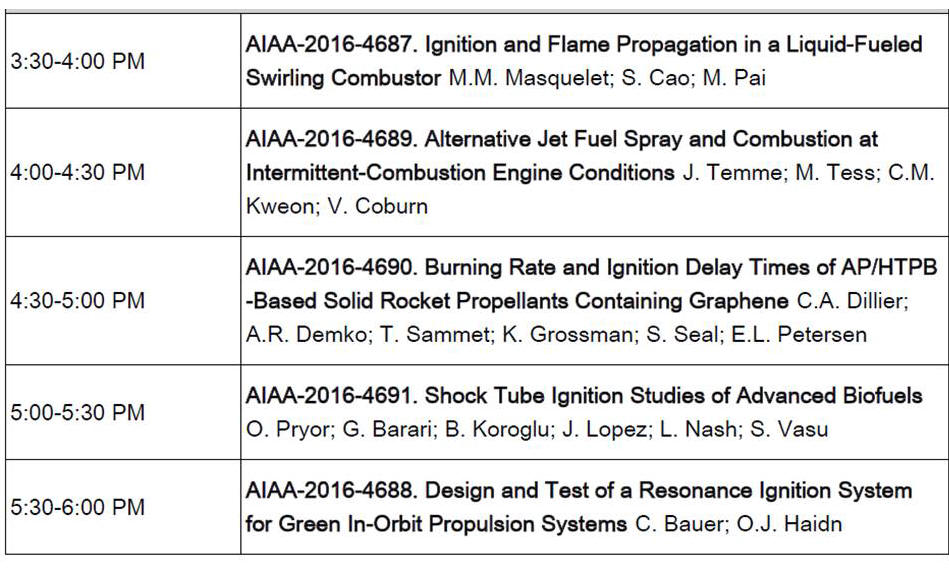

On July 10, 2017,

Dr.

Chehroudi attended the

AIAA Propulsion & Energy Forum held in Atlanta, Georgia. He was

also a Session Chair for the "Combustion Instability I" in which the

following five technical papers were presented. Session Chairs are

responsible of review of the original extended abstract submitted

and based on that invite for full paper submission.

Numerical Simulation of

Thermoacoustic Combustion Instabilities in the Volvo Combustor (E.

Gonzalez, Combustion Science & Engineering Inc.)

Quantitative Comparisons Between LES

Predictions and Experimental Measurements of Sound Pressure Spectra

in a Confined Swirl Combustor (M. Merk, Technical University of

Munich, Munic, Germany; R. Gourdron, M. Gatti, C. Mirat,

CentraleSupelec, Paris, France; W. Polifke, Technical University of

Munich, Munich, Germany; T. Schuller, CentraleSupelec, Paris,

France)

Development of a Novel Approximate

Solution to teh Acoustic Wave Equation with ean Gradient and its

Application to Predicting Combustion Instabilities in a Dump

Combustor (V. Rani, S. Rani, University of Alabama, Hunsville, AL)

Large-Eddy Simulation of

Single-Element Gas-Centered Swirl-Coaxial Injectors for Combustion

Instability Prediction (C. Umphrey, Sierra Lobo, Inc., Edwards AFB,

CA; M. Harvazinski, S. Schumaker, V. Sankaran, Air Force Research

Laboratory, Edwards AFB, CA)

Time-resolved Single-Element

Gas-centered Swirl-Coaxial Injector Simulations for Combustion

Stability Prediction (C. Lietz, Sierra Lobo, Inc., Edwards AFB, CA;

M. Harvazinski, S. Schumaker, V. Sankaran, Air Force Research

Laboratory, Edwards, AFB, CA)

On July 10, 2017, Dr Chehroudi as a

Senior members of the Propellant and Combustion Technical Committee,

attended the evening meeting with the rest of the members. Topics

such as management of technical sessions and papers, creation of new

technical sessions, Best Paper awards, Student Best Paper, Year-End

highlights of technical progress and advances, continuing education,

membership, etc.

_______________________________________________

On July 10, 2017, Dr Chehroudi as

a Senior members of the

Propellant

and Combustion Technical Committee, attended the evening meeting

with the rest of the members. Topics such as management of technical

sessions and papers, creation of new technical sessions, Best Paper

awards, Student Best Paper, Year-End highlights of technical

progress and advances, continuing education, membership, etc.

_______________________________________________

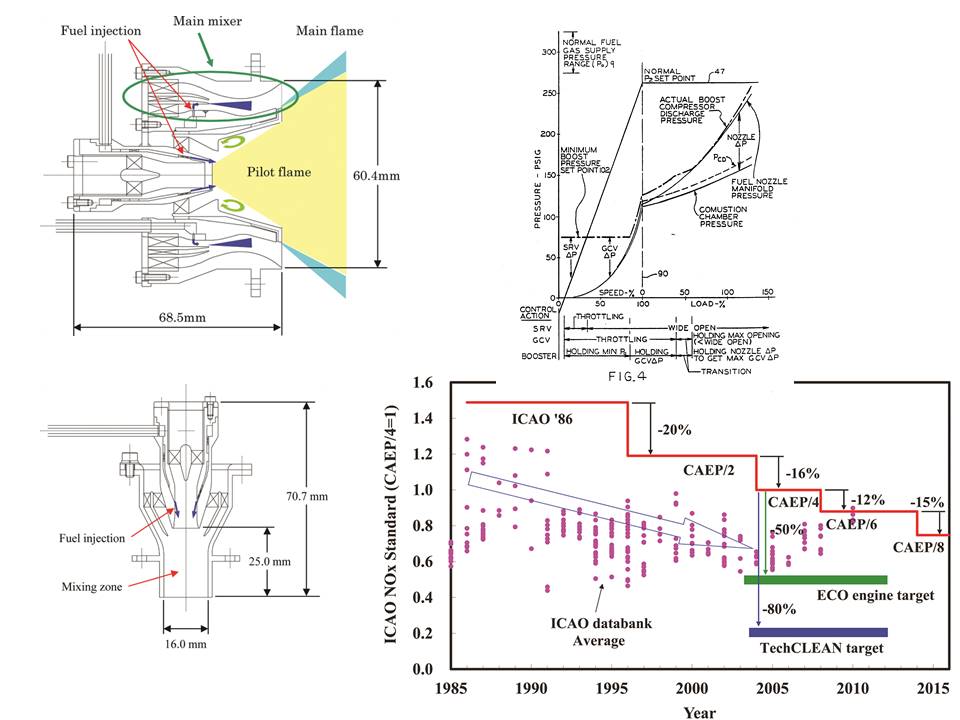

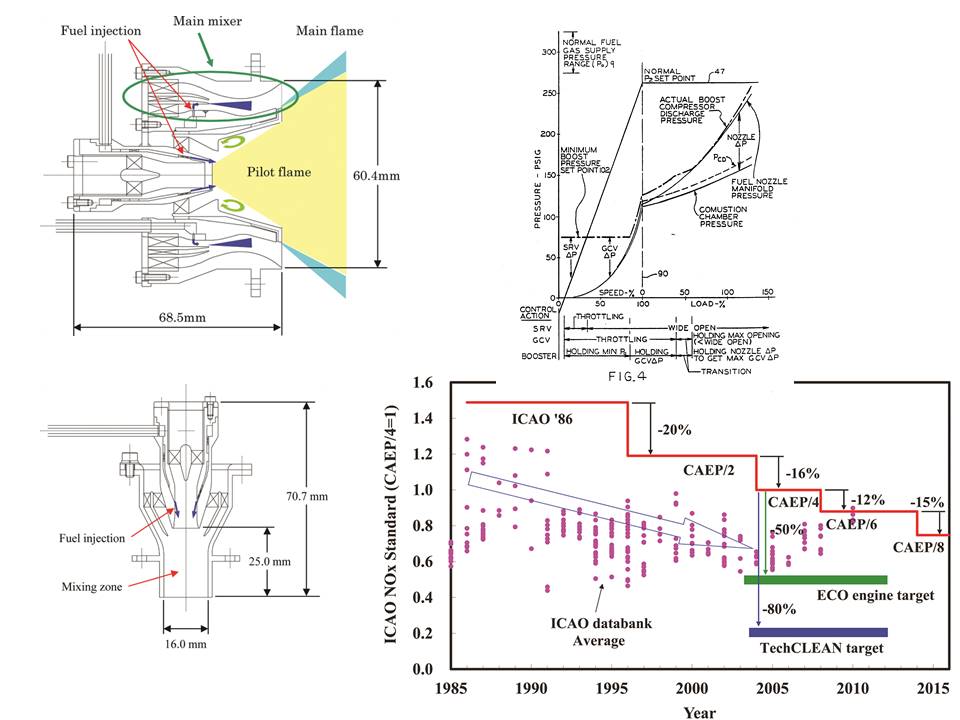

On May 22 to 24, 2017, Dr.

Chehroudi is invited by the American Society of Mechanical Engineers

(ASME) to conduct a seminar on

Combustion and Emission of Pollutants from Gas Turbine Engines.

Attendees are design engineers,

combustion engineers, technical managers, research

scientists/engineers, and specialists in the field.

Controlling the emission of

pollutants from gas turbine engines, whether they come from

aircraft, ground-based energy conversion or mechanical drives, is

one of the grand challenges of our time. Design strategies for many

gas turbine components, specifically combustors and fuel nozzles,

require a thorough understanding of the control of regulated

combustion pollutants released into the atmosphere.

This course presents a balanced look

at current and future low-emission design strategies for both

aircraft and ground-based gas turbine engines. It demonstrated that

the formation mechanisms for the regulated pollutants is critical

for efficient engineering design strategies and technology

development.

The course will over a wide range of

topics, including premixed or partially-premixed combustor designs,

staging in lean-premixed prevaporized (LPP) mixture and its

consequences on designs of the combustor, prevaporization,

combustion efficiency, lean stability, auto-ignition, flashback,

fuel nozzles, and lean direct injection (LDI).

Operability issues (such as part-load

emissions, stability and lean blowout, ignition, thermal

managements, pattern factor, combustor pressure losses, combustion

oscillations, and alternative fuels) will also be discussed.

Using case studies from manufacturers

and technology developers, the class discussion will emphasize the

system-level and practical issues that must be addressed in

developing different types of gas turbines that emit pollutants at

acceptable levels. The course will be especially valuable to those

who are new in the field as well as those who wish to increase their

understanding of gas turbine emission control strategies. For more

information please visit www.asme.org

.

_______________________________________________

On May 15 to 17, 2017, Dr.

Chehroudi is invited by the Society of Automotive Engineers (SAE),

to conduct a seminar on Combustion and Emission of Pollutants from

engines.

Attendees are design engineers,

combustion engineers, technical managers, research

scientists/engineers, and specialists in the field.

Combustion is a key element of many

of modem society’s critical technologies. Electric power production,

home heating, ground transportation, spacecraft and aircraft

propulsion, and materials processing all use combustion to convert

chemical energy to thermal energy or propulsive force. Although

combustion, which accounts for approximately 70 percent of the

world’s energy usage, is vital to our current way of life, it poses

great challenges to maintaining a healthy environment. Improved

understanding of combustion will help us deal better with the

problems of pollutants, atmospheric change and global warming,

unwanted fires and explosions, and the incineration of hazardous

wastes. Despite vigorous scientific examination for over a century,

researchers still lack full understanding of many fundamental

combustion processes. The list below shows key topics discussed with

reference to many applications in design and engineering of relevant

components. For more information, please visit www.sae.org.

_Hydrocarbon and alternative fuels

_Distillation curve for fuels and its importance

_Distinction between "overall" A/F and cylinder-based, or local A/F

_Black-box operation of the "oxygen sensor" and its purposes

_Equivalence ratio and "lambda" _Adiabatic flame temperature and its

physical meaning/importance

_Heating value

_Combustion efficiency

_Equilibrium and chemical kinetics

_Concept of "mechanism" of overall reaction

_The nature of (heterogeneous) catalytic reaction on surfaces

_Flame propagation

_Laminar burning speed

_Turbulent flames

_Effects of turbulence on flame propagation

_Effects of residual burned gases (or EGR) on Flame propagation

_Impact of multiple spark plugs on flame propagation

_Cylinder pressure measurements and its behavior

_Effects of spark timing (advance/retard) on cylinder pressure

_Mass fraction burned curve & heat release analysis _Autoignition

and Knock in SI engines

_Physical meaning of "specific heat"

_Cyclic variability and how it is quantified

_Mixture preparation

_Effects of design and operating conditions on combustion & emission

of pollutants

_Diagnostics

_Laser and optical diagnostics for engine research

_Case studies and discussions

_______________________________________________

Dr. Chehroudi acted as a member of

the PhD Committee for Dr. Luciano Strafella from Department of

Innovation Engineering, University of Salento, for

his work titled " A Novel Approach to Initiate Combustion:

Performance and Application Potential in Internal Combustion

Engines. Dr. Chehroudi was involved in the progress and direction of

the work and reviewed / commented on the dissertation. May 4, 2017.

_______________________________________________

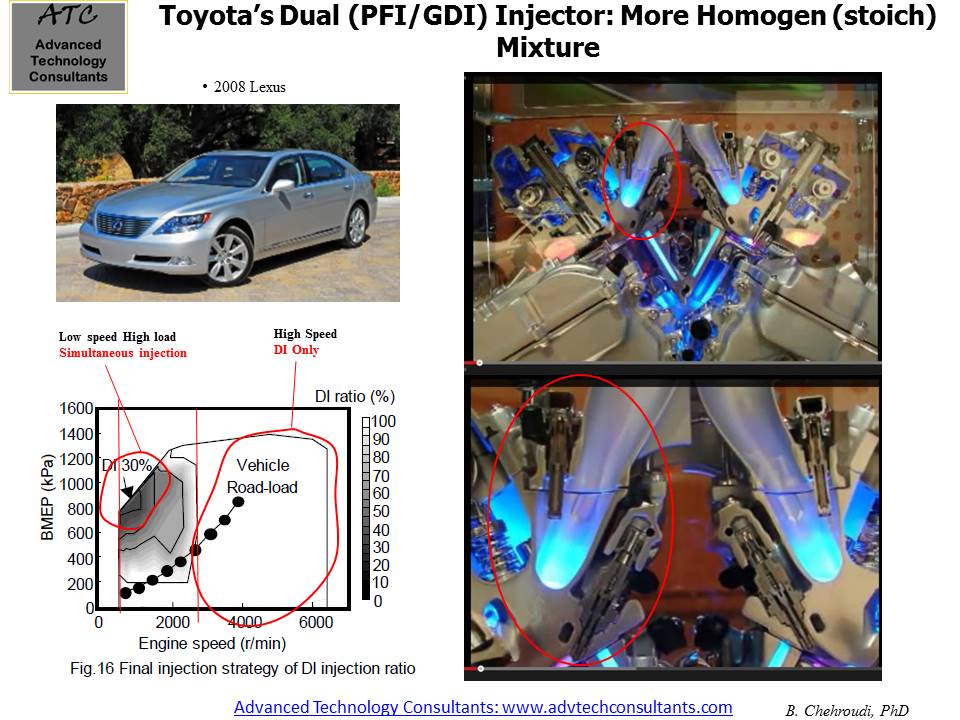

On March 20- 22, 2017, Dr.

Chehroudi was an invited speaker by the Society of Automotive

Engineers, to conduct a seminar on Gasoline Direct Injection (GDI)

in Troy, Michigan.

This is a highly updated version of

the seminar introduced in 2010 which, in view of recent market share

of GDI Engines, has become a very popular professional seminar to

attend amongst R&D/application engineers, researchers, technical

managers, regulators, and policy makers.

The objective of the seminar is to

present adequate information on combustion and emission of

pollutants for GDI engines in order to elevate attendee's background

knowledge for an intelligent application and comfortable

understanding of the existing body of knowledge in direct injection

spark ignition engines. Below is the table of content for this

seminar:

●Mixture Formation

●In-cylinder flow characteristics and GDI

combustion

●Fuel-air mixing process

●Spray-wall interactions

●Cold start and wall wetting issues

●Combustion Process and Control Strategies

●Engine Operating Modes and Fuel Injection Strategies

●Early-injection, late-injection, stoichiometric operation

●Operating mode transition

●Split Injection Strategy

●Two-stage, split, and post injection

●Combustion characteristics

●Homogeneous-charge and stratified-charge

combustion

●Effects of Engine Operating and Design Parameters on GDI Combustion

●Injection and ignition timings

●Spray cone angle

●EGR

●Knock resistance characteristics

●Air-assisted versus single-fluid GDI fuel system

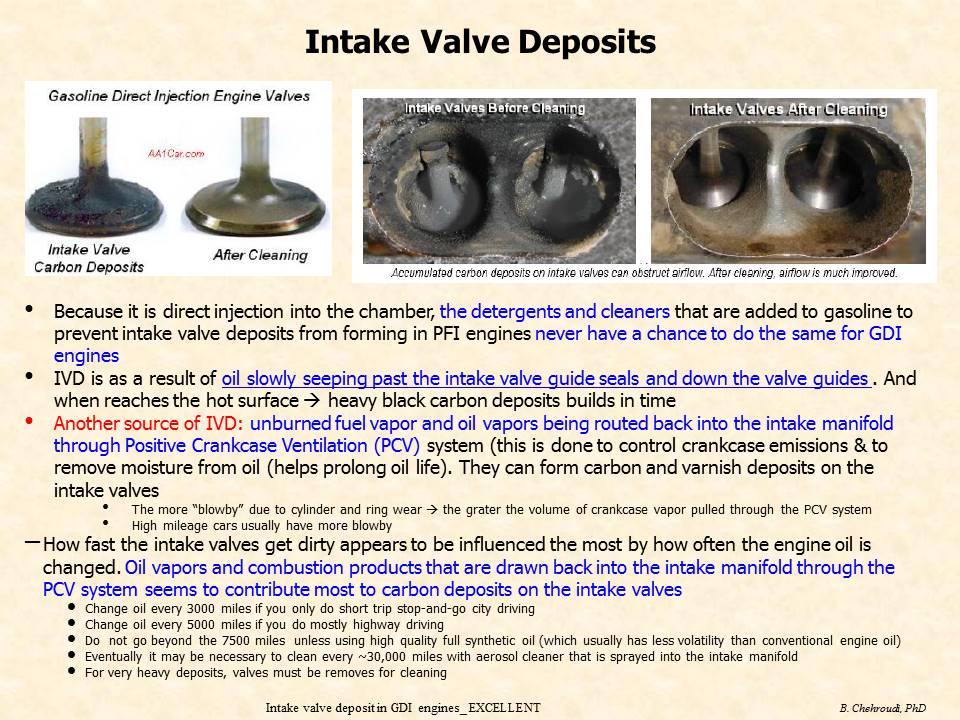

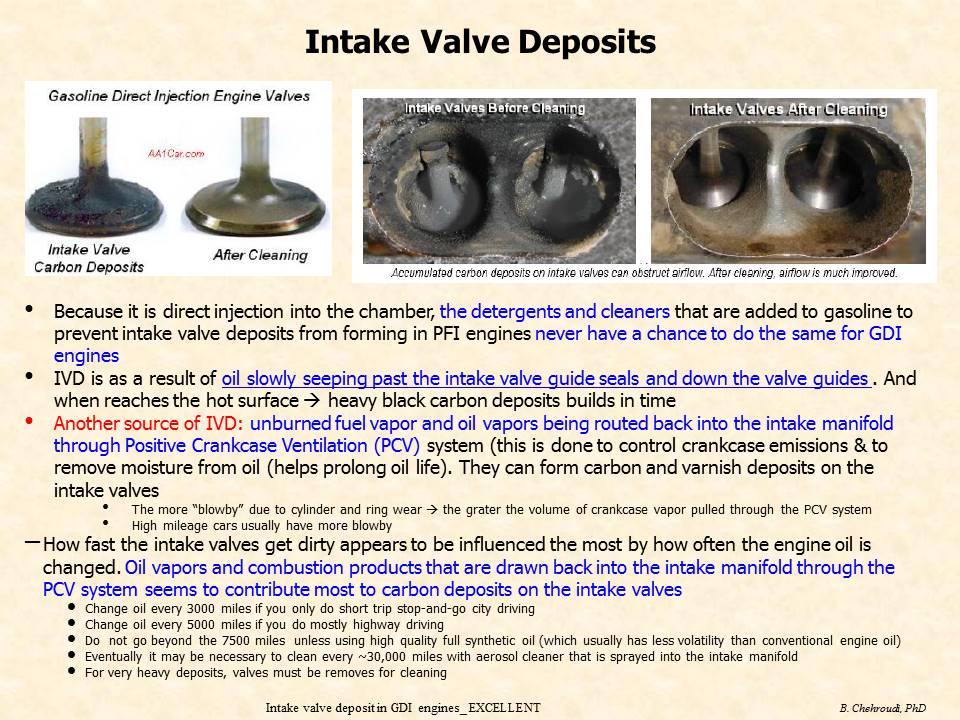

●Injector, Combustion Chamber, and Intake Valve Deposits

●Emissions of Pollutants - Reduction Approaches

●Hydrocarbon, NOx and particulate

●Fuel Economy

●Factors affecting improved fuel economy

●Fuel economy versus emissions compromise

●Select Gasoline Direct-Injection Engines

●Benefits of Turbocharging a GDI engine

_______________________________________________

On January 11, 2017, Dr. Chehroudi

chaired a technical session on Combustion Dynamics during the

Science and Technology Forum

and Exposition (SciTech 2017),

American Institute of Aeronautics and Astronautics (AIAA) ,

Grapevine, Texas, Jan 9-13, 2017.

Speakers from Air Force Research

Laboratory, Georgia Tech University, University of Cambridge,

Sapienza University of Rome, University of California at Los Angeles

(UCLA), and Purdue University presented their research.

_______________________________________________

Invited Speaker by the

American Institute of Aeronautics and Astronautics to conduct a

two-day seminar on Liquid Atomization, Sprays, and Fuel Injection in

Aircraft Gas Turbine Engines (January 7-8, 2017), AIAA Science

and Technology Forum and Exposition (SciTech 2017), Grapevine,

Texas, Jan 9-13, 2017.

Atomization of liquids is at the

heart of operations of many of the devices we use on a daily basis.

From our shower in the mo rning

(water atomization at the shower head), to liquid-fueled engines in

ground transportation (gasoline and diesel engines), to gas turbine

in airplanes/power stations and rocket engines. Other areas such as

electrostatic car-body spray painting, agricultural crop spraying,

ink jet printing, pharmaceutical nebulizers, spray drying,

and chemical liquid rockets, are just a few examples of the very

wide applications of the liquid spray production technology. rning

(water atomization at the shower head), to liquid-fueled engines in

ground transportation (gasoline and diesel engines), to gas turbine

in airplanes/power stations and rocket engines. Other areas such as

electrostatic car-body spray painting, agricultural crop spraying,

ink jet printing, pharmaceutical nebulizers, spray drying,

and chemical liquid rockets, are just a few examples of the very

wide applications of the liquid spray production technology.

In the aerospace industry, the engine

thrust, efficiency, and the emission levels are directly related to

the performance of the liquid fuel injector designs. For this

reason, R&D activities in this area have intensified in the past two

decades in a quest to

design and operate efficient and

low-emission gas turbine engines. It is imperative then individuals

involved in research, design, and operation have the requisite

knowledge and training to choose intelligent and innovative

approaches when it comes to liquid fuel nozzle and its optimum

performance.

This seminar is about understanding

the processes of liquid atomization and spray formation and relating

this understanding to fuel injection systems and emission of

pollutants in modern engines. The approach in this course is to

build sufficient background through introduction of a consistent and

widely-used terminology in sprays and atomization. Justifications,

reasons, and purposes of the liquid atomization and spray formation

are discussed along with presentation of different designs of

atomizers and nozzles employed in various industries.

Characterization methods of sprays are discussed after the

definition and meaning of different averaged liquid droplet

diameters are touched. Droplet size measurement devices are covered

and examples are shown. Armed with these critical background

information, the focus of the course is then heavily directed to gas

turbine fuel nozzle designs and their performance requirements for

optimum engine operation with lowest possible emission of harmful

pollutants.

_______________________________________________

Dr. Chehroudi is a member of the

Organizing Committee for the 5th International Conference and

Exhibition on Mechanical & Aerospace Engineering to be held in

Las Vegas, Nevada, USA, October

2-7, 2017. The conference theme is New Advancements and Innovations

in Mechanical & Aerospace Engineering.

_______________________________________________

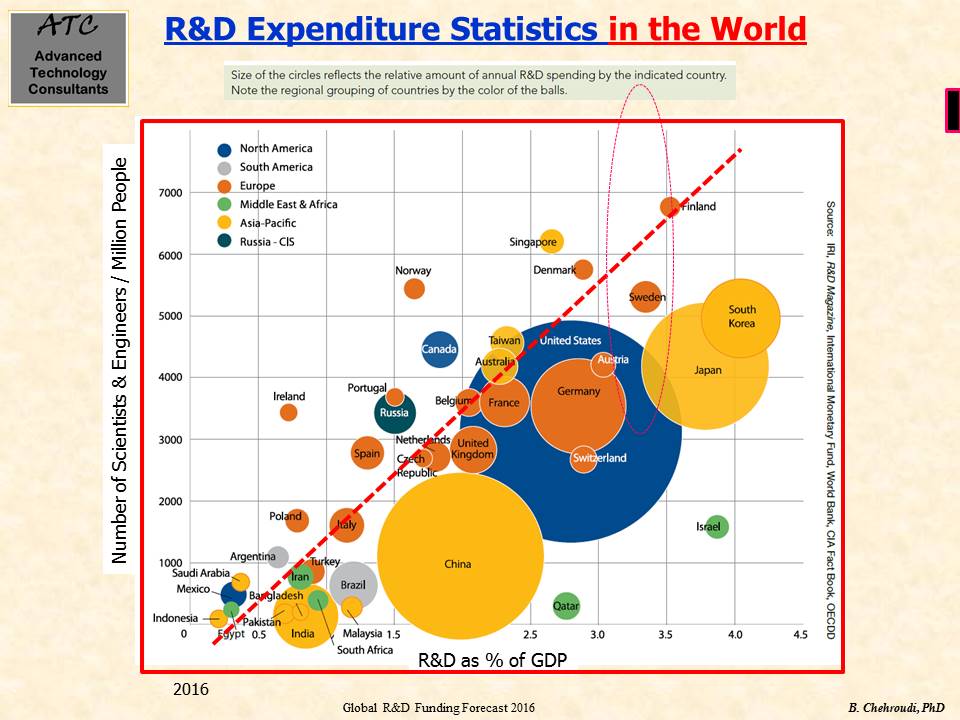

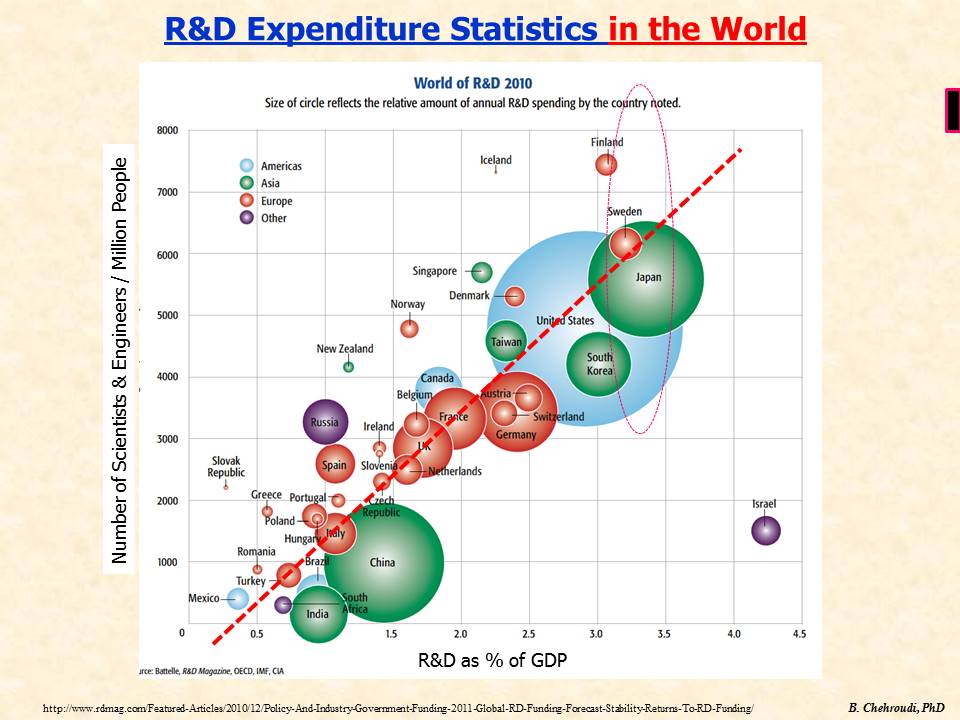

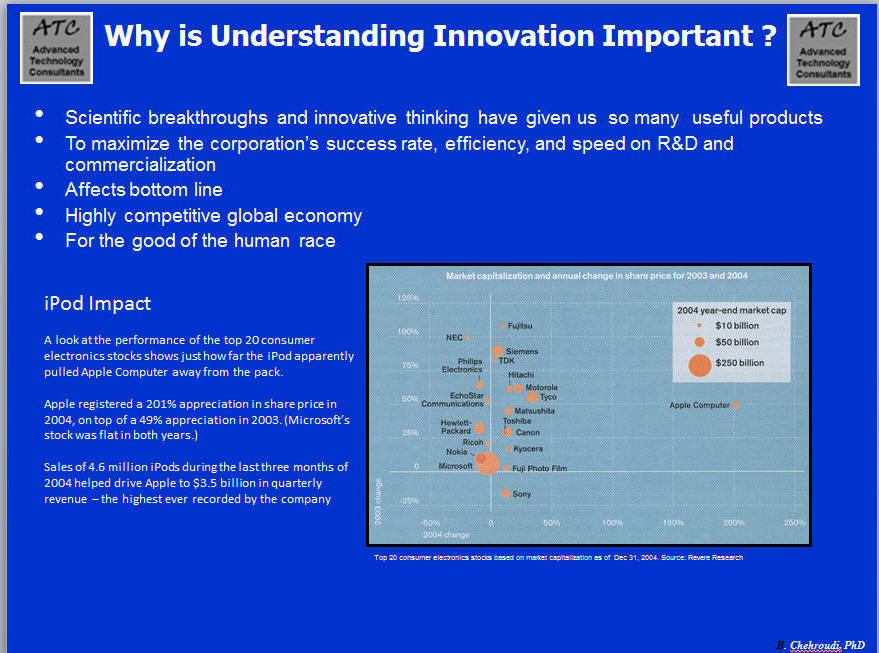

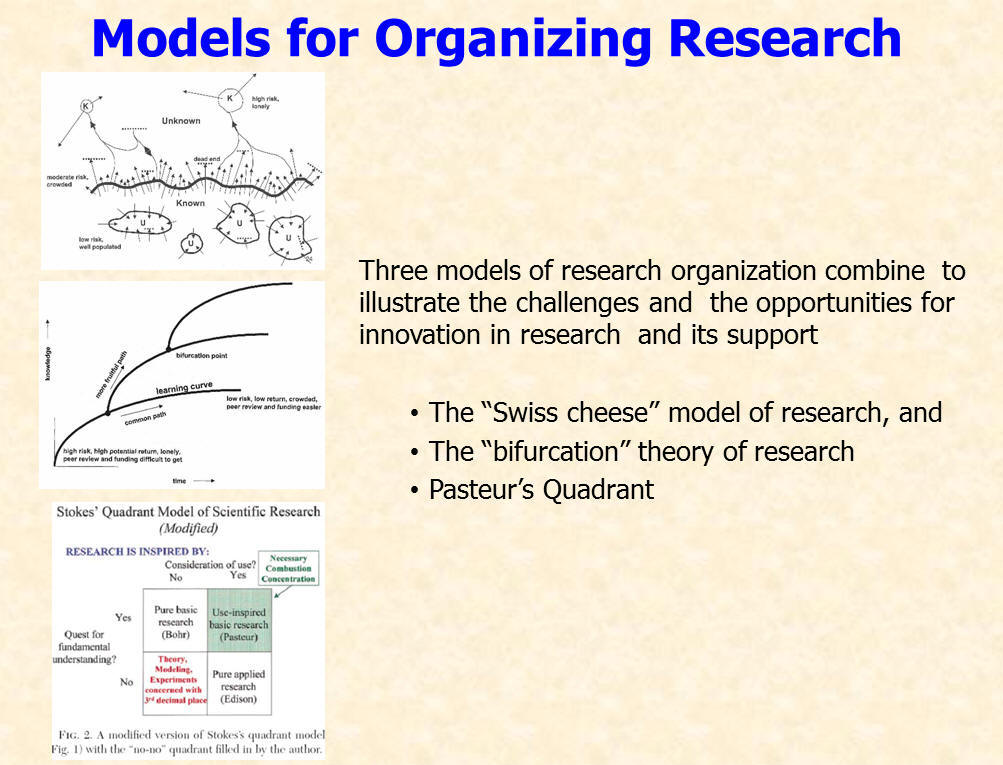

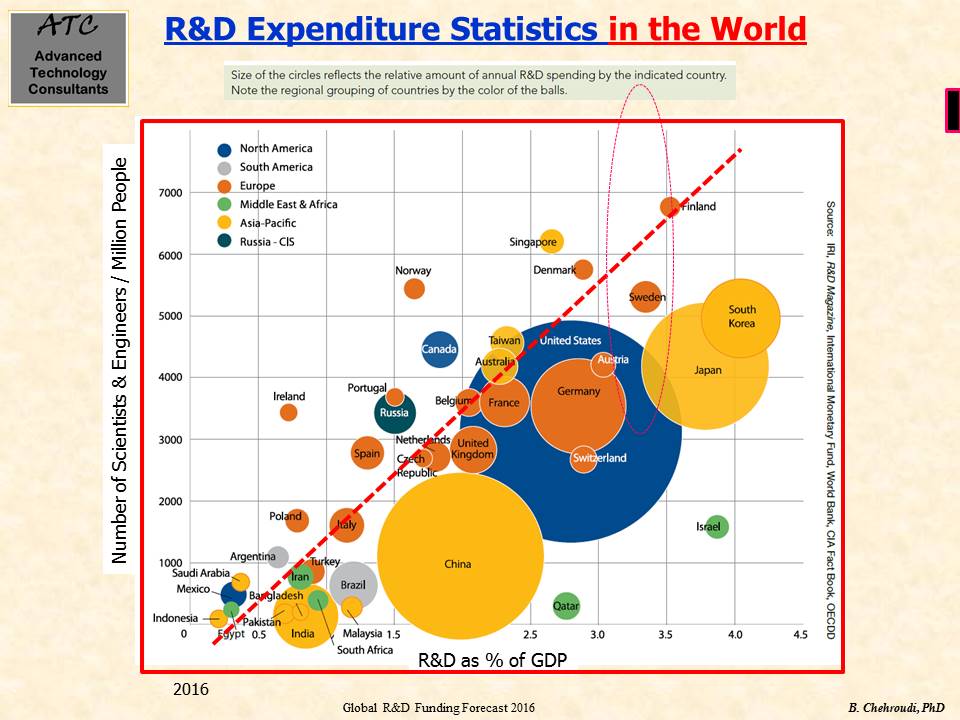

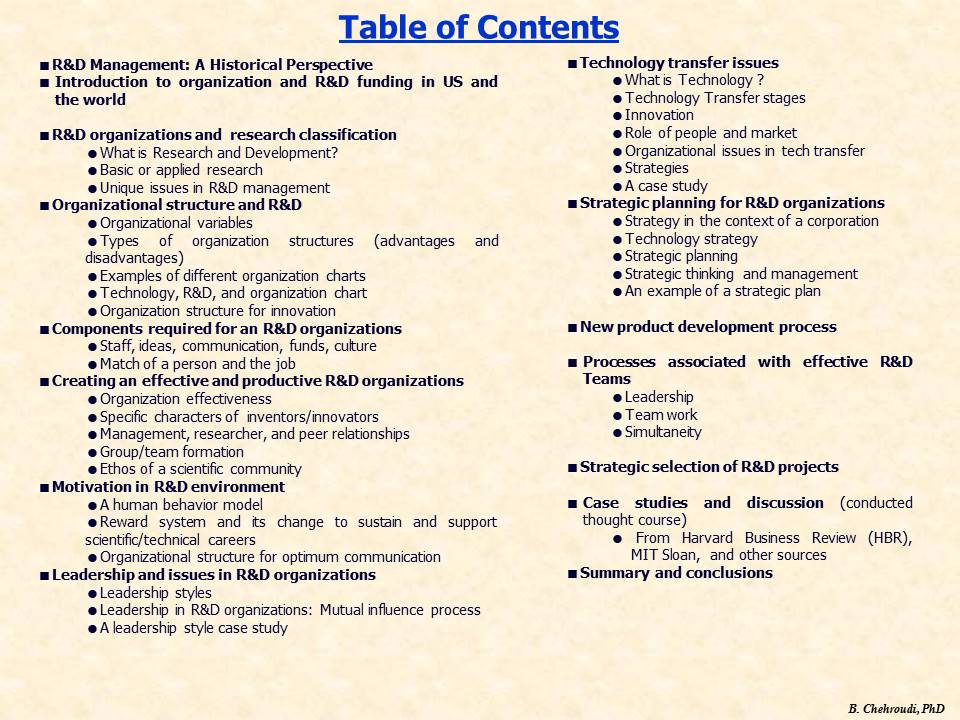

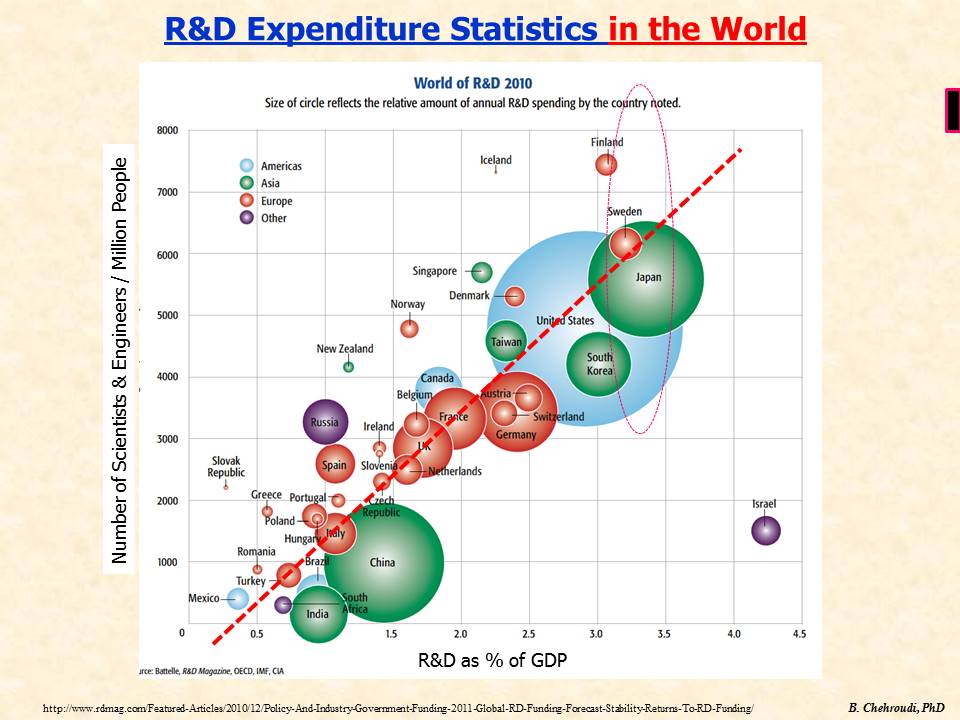

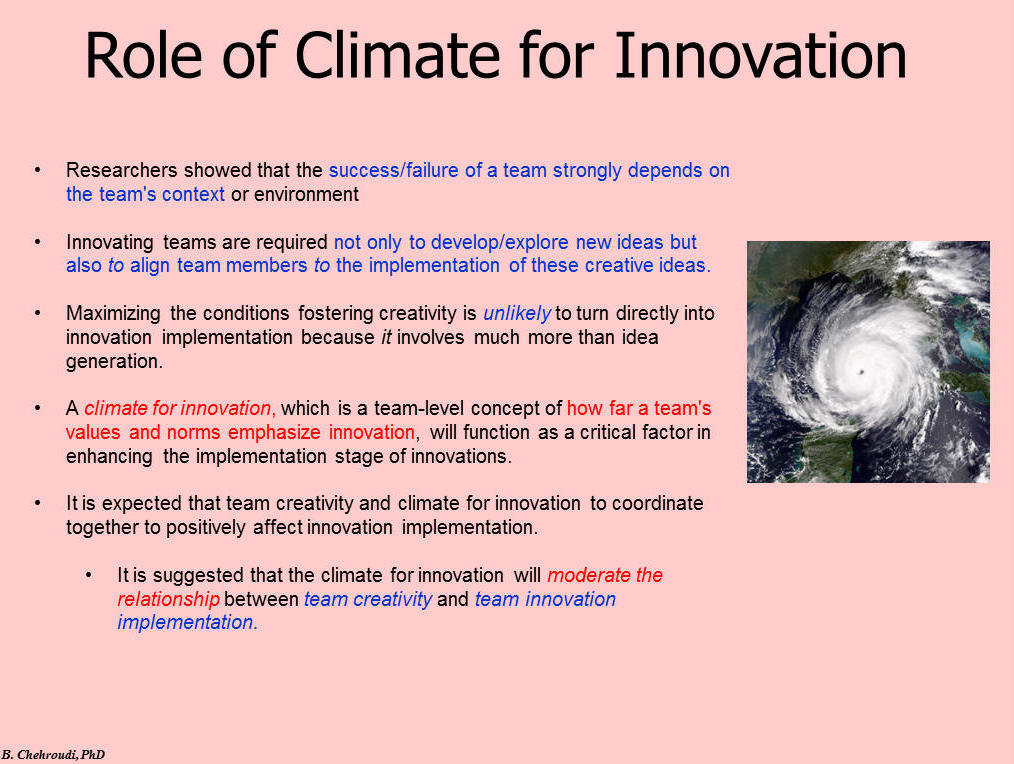

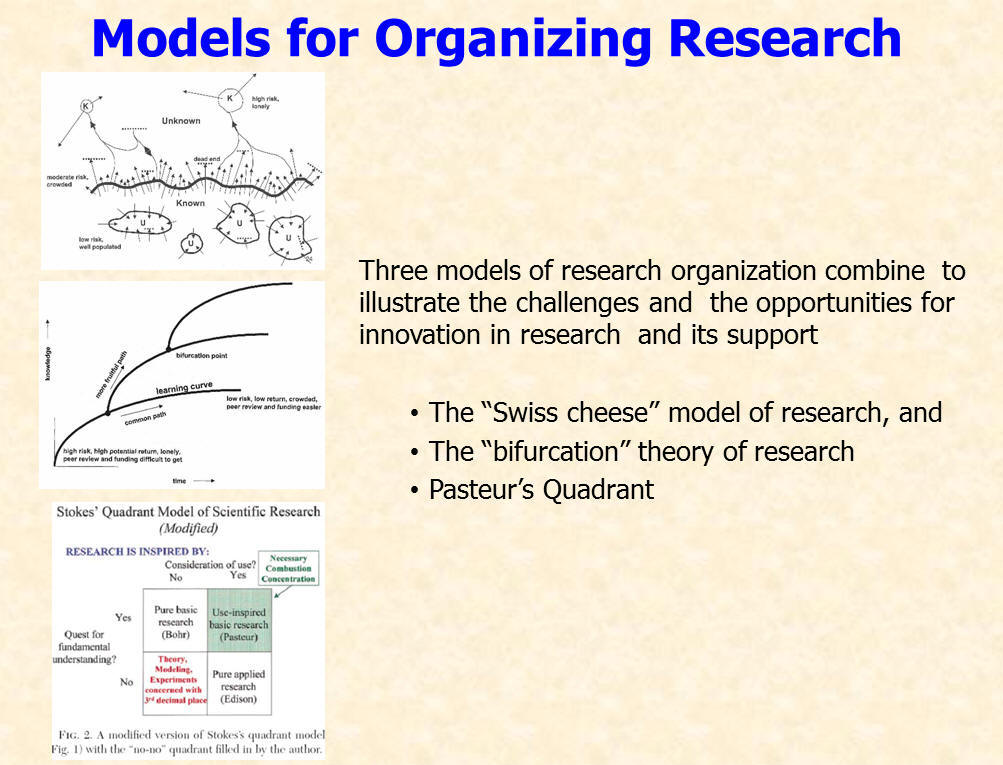

On November 14-16, 2016, Dr. Chehroudi

will be an invited speaker by the American Society of

Mechanical Engineers (ASME) to deliver a 3-day seminar on

Effective Management of Research and Development in San Diego,

California.

In today's technology-driven global economy, innovation is at the

core of the survival-of-the-fittest organization. The innovation

process begins with the identification of market needs or technology

opportunity and then goes through stages, such as adopting or

adapting existing technology that satisfies the identified need or

opportunity, inventing when needed, and finally transferring this

technology by commercialization or other instrumental means.

Effective and efficient R&D management can have profound and

determining consequences, considering the key role it plays in the

economic health of a nation and the world as a whole, the

profitability of a business enterprise, the effectiveness of a

technology-based governmental agency, and the enormous investment

nations make in R&D activities. Today, the complexity of the

technology creates complex organizations in which many disciplines

have to be coordinated. It is the manager's primary responsibility

to bring components together so they can operate smoothly and

harmoniously, each making an optimal contribution to the R&D

organization.

_______________________________________________

On August 8 to 10, 2016, Dr. Chehroudi

was an invited speaker at the US Army, Redstone Arsenal in

Huntsville, AL to give a talk on Liquid

Atomization, Sprays, and Fuel Injection.

Dr Chehroudi discussed some of

the advances in liquid atomization, sprays and fuel injection and

their applications in advanced small diesel engines. Dr

Chehroudi discussed some of his ideas, particularly the

"Interacting-Sprays Injection System" in order to have equal or even

better atomization quality while lowering the system weight for

small engine applications. The concept of Interacting-Sprays

Injection System was first proposed by Chehroudi's group, something

that was inspired by impinging-jets injectors in liquid rocket

engines. Mr. Joseph A Gibson, US Army Propulsion Division,

Small and Certified Engines Team,

was his host.

This in-house seminar was organized

by the Society of automotive Engineers (SAE).

_______________________________________________

On July 25 to 27, 2016, Dr.

Chehroudi has conducted a 3-day seminar on Gasoline Direct

Injection (GDI) engines in Troy, Michigan.

This is a seminar introduced in 2010

which, in view of recent market share of GDI Engines, has become a very

popular professional seminar to attend amongst R&D/application engineers, researchers, technical

managers, regulators, and policy makers.

The objective of the

seminar is to present adequate information on combustion and

emission of pollutants for GDI engines in order to elevate

attendee's background knowledge for an intelligent application

and comfortable understanding of the existing body of knowledge in

direct injection spark ignition engines.

_______________________________________________

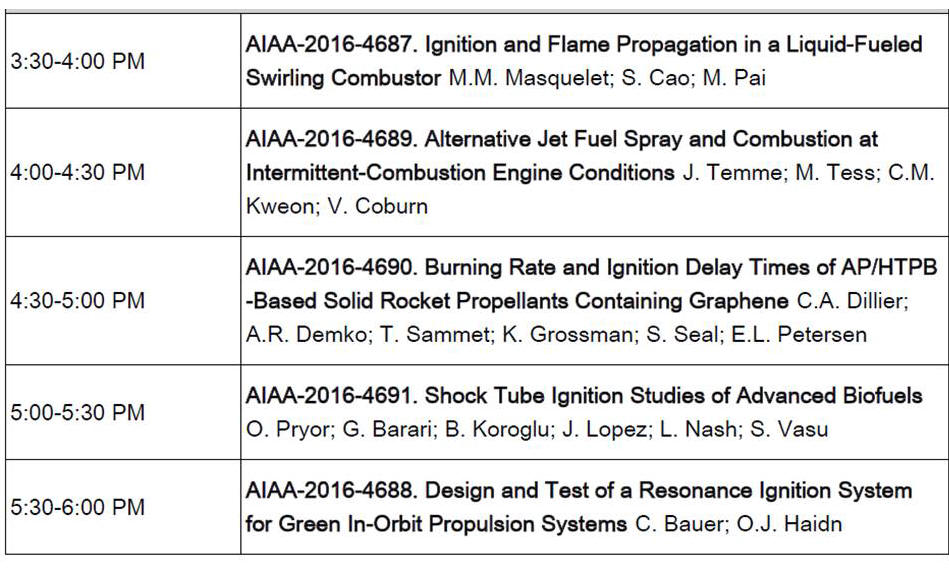

Dr. Chehroudi will be chairing a

session on Ignition in Propulsion Systems during the 2016 American

Institute o f

Aeronautics and Astronautics (AIAA) held in

Salt Palace Convention Center, Salt Lake City, Utah, July

25 - 27. The following papers will be presented in this session. f

Aeronautics and Astronautics (AIAA) held in

Salt Palace Convention Center, Salt Lake City, Utah, July

25 - 27. The following papers will be presented in this session.

_______________________________________________

On June 16, 2016, Dr. Chehroudi

was an invited speaker at the

Kasetsart University (KU), Bangkok, Thailand.

This

meeting was kindly organized by

Prof. Klanarong Sriroth who is also a distinguished member of the

Board of

Directors of the

Mitr Phol company. Dr. Chehroudi presented a work

on university-industry collaboration on R&D, titled

"Corporate-University R&D," to a large number of attendees:

Click on the

KURDI link. During

this visit he has the opportunity and the honor to meet with the

President of the university (Dr. Chongrak Wachrinrat), Vice

President for Research (Dr. Siree Chaiseri), and

Director of the

Research and Development Institute (KURDI) (Dr. Thongchai Sunwonsichon).

During this visit he was kindly escorted by Prof. Chinnathan

Areeprasert, from the Mechanical Engineering department. This

meeting was kindly organized by

Prof. Klanarong Sriroth who is also a distinguished member of the

Board of

Directors of the

Mitr Phol company. Dr. Chehroudi presented a work

on university-industry collaboration on R&D, titled

"Corporate-University R&D," to a large number of attendees:

Click on the

KURDI link. During

this visit he has the opportunity and the honor to meet with the

President of the university (Dr. Chongrak Wachrinrat), Vice

President for Research (Dr. Siree Chaiseri), and

Director of the

Research and Development Institute (KURDI) (Dr. Thongchai Sunwonsichon).

During this visit he was kindly escorted by Prof. Chinnathan

Areeprasert, from the Mechanical Engineering department.

Dr. Chehroudi has also met the

following members of the university community:

Dr. Punpiti Piamsa-nga, Deputy

Director for IT & Associate Professor

Dr. Wirat Vanichsriratana, Assistant Dean for Information Systems

Dr. Vejapong Juttijudata, Associate professor, Department of

Aerospace Engineering

Dr. Prapot Kunthong, Head of Department of Mechanical Engineering

Dr. Peerayuth Charnsethikul, Dean, School of Engineering

Dr. Tanet Aroonsrisopon, Deputy Head of Mechanical Engineering

Department

Dr. Chawalit Kittichaikarn, International Undergraduate Program

Director

Dr. Orapin Chienthavom, Vice Dean for Research and International

Affairs

Dr. Chaiwat Klampol, Department of Aerospace Engineering

Dr. Wichai Siwakosit, Rail Engineering Program Director

During this visit, Dr Chehroudi

and the

Kasetsart University discussed avenues in which they can

cooperate on matters related to Research and Development and

industry collaborations. Some suggestions were made to pursue

the matters in the near future.

_______________________________________________

From June 12 to 15, 2016, Dr.

Chehroudi was an invited consultants for the

Mitr Phol company

in Thailand. Dr. Chehroudi and Ms. Hooshmand acted as

consultants regarding the training and future growth of company's

innovation and management of research and development (R&D).

This meeting was initiated by

Prof. Klanarong Sriroth who is also a distinguished member of

the Board of Directors of the

Mitr Phol company.

This meeting was initiated by

Prof. Klanarong Sriroth who is also a distinguished member of

the Board of Directors of the

Mitr Phol company.

Dr. Chehroudi and Ms. Hooshmand also

had a great pleasure of meeting Prof. Dr. Pavinee Chinachoti,

President of the FoSTAT (www.fostat.org).

The

Mitr Phol company

is a privately-owned group of companies, mainly owned by the

Vongkusolkit family. It is now ranked as the world's third

largest sugar producer, and the largest producer in Asia. It is

Thailand's largest sugar producer and the 2nd largest in China

through its joint venture company East Asia Sugar. In addition to

Thailand and China, Mitr Phol has operations and investments in Lao

PDR, Cambodia, and most recently Australia. Its key business units

include sugar, wood substitute materials, and renewable energy.

Dr. Chehroudi had opportunities to

meet the following distinguished members of the Mitr Phol:

Mr. Suppapong Sooksangchaya, Vice

President, Sugar Farm Technology and Management, Mitr Phol Sugar

Corp., Ltd.

Mr. Chusak Vongkusolkit, Chief

Operating Officer, China Business Group

Mr. Borwornman Thongkalya, Senior Executive VP, Human Resources and

Management Group

Mr. Apiwat Boonthawee, Executive VP, Sugarcane Management (Central

Area)

Dr. Sarayuth Saengchan, Senior Executive VP, Finance

Mr. Paitoon Praphatharo, Executive VP Sugarcane Management

(Northeast Area 2)

Mr. Ali Sajjad Dharamsey, Executive VP, International Sales and

Molasses Marketing Group

Mr. Worrawat Sriyook, VP, Risk Management, Safety Occupational

Health and Environment

Dr. Sunisa Chatsurachai, Senior

Researcher (Bioinformatics), Research & Development Division,

Innovation and Research Center, Mitr Phol Sugarcane Research Center

Co., Ltd.

Dr. Sansanalak Rachawong, Senior Manager - Bio-based Chemicals &

Energy, Research & Development Division, Innovation and Research

Center, Mitr Phol Sugarcane Research Center Co., Ltd.

Mr. Piyanan Tessen, Researcher (Technology Analyst), Mitr Phole

Sugarcane Research Center Co., Ltd

Pichai Noonto, Manager, Office of

Senior Executive VP, Manufacturing

Krist Kroopasa, Human Resources Manager (Phu Vieng), Human Resources

Department, United Farmer & Industry Co., Ltd.

Dr. Jetnapa Techawipharat, Deputy

Manager, Corporate Strategy, Mitr Phol Sugar Corp., Ltd.

Suchat Olannaranon, Business Analyst, Mitr Phol Sugar Corp. Ltd.

Mr. Reaz Sheriff, Group Managing

Director, Panel Plus Co., Ltd., Mitr Phol Group

_______________________________________________

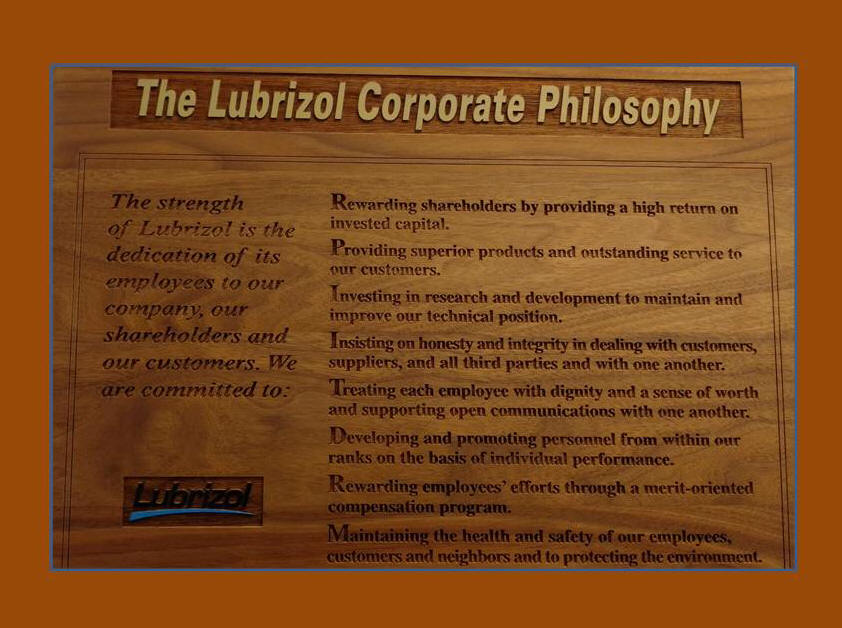

On Monday, May 25 - 27,

2016, Dr. Chehroudi was an invited speaker by the

Lubrizol Corporation (R &D

Center), to conduct an in-house seminar on Gasoline Direct Injection

(GDI), Additives, and Deposit Formations in Wickliffe, Ohio. &D

Center), to conduct an in-house seminar on Gasoline Direct Injection

(GDI), Additives, and Deposit Formations in Wickliffe, Ohio.

This is a

specially prepared seminar for Lubrizol that is supplemented and

enhanced with information on additives and deposit formation issues

in injectors, combustion chamber, and valves.

The objective of the

seminar was to present adequate information on combustion and

emission of pollutants, additives and deposit formation in GDI engines in order to elevate

attendee's

background knowledge for an intelligent application and comfortable

understanding of the existing body of knowledge in direct injection

spark ignition engines.

During this visit, Dr.

Chehroudi Met with some of the senior members of the engine oil and fuel

testing as well as R&D centers. There were exchanges of

information. The ATC and Lubrizol explored avenues for future

collaborations in areas of mutual interest.

_______________________________________________

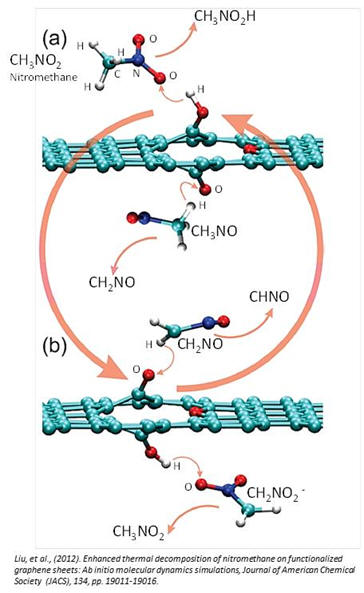

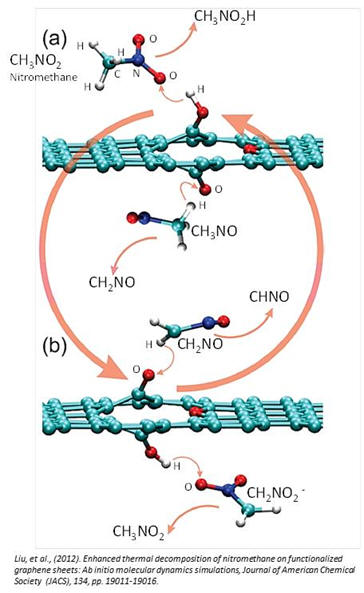

In 2016, Dr. Chehroudi's paper

on applications of

Graphene (a nanotechnology product) in fuels and combustion

systems has been published by the special volume of the

CRC

Handbook of Graphene Science - Applications and Industrialization, Taylor and Francis. The title of the article is "Applications of Graphene in

Fuel/Propellant Combustion". The set includes

contributions from top researchers in the field and a foreword

written by two Nobel Laureates in Physics. Below, is the abstract of this work:

Graphene is the

strongest material ever studied and can be an efficient substitute

for silicon. This six-volume handbook focuses on fabrication

methods, nanostructure and atomic arrangement, electrical and

optical properties, mechanical and chemical properties,

size-dependent properties, and applications and industrialization.

There is no other major reference work of this scope on the topic of

graphene, which is one of the most researched materials of the

twenty-first century. The set includes contributions from top

researchers in the field and a foreword written by two Nobel

laureates in physics.

Abstract

Use of nanostructured

materials, in particular graphene, in combustion and ignition of

fuels has recently shown promising results to enhance fuel burn rate

and potential for light-activated volumetrically-distributed

ignition. For example, addition of functionalized graphene (FG)

sheets to nitromethane, has been demonstrated to act as a catalyst

and substantially increase the linear burning rate of the fuel.

Functionalization of the graphene is considered as a great

opportunity for tailor-made material with specific properties of

interest. For example, it consists of chemical functional groups on

the surface such as epoxides and hydroxides and on the edges of the

sheet as hydroxides and carboxylates. These oxygen-containing

functionalities bring about catalytic properties for fuel

decomposition and other intermediate fragments during the fuel

oxidation process. The defect structures in the FG sheets have also

been shown to act as active sites. Such augmented fuel thermal

decomposition and its derivatives have been verified through use of

molecular dynamics (MD) simulations. FG sheets are easily

dispersible in many hydrocarbon fuels and propellants with no need

for surfactants and may also offer a substantially higher surface

area than other nanostructured materials such as metal oxides and

carbon nanotubes. Also, because FG is entirely oxidized in high

temperature combustion zones with virtually no additional residues

other than the common combustion products, it can be viewed as a

fuel supplement, contributing towards the energy density. In this

paper, applications of the graphene oxides and FG sheets in ignition

and combustion of fuels are briefly reviewed, highlighting

potentials and future prospects of these materials.

Table of Contents

BIOMATERIAL

Design and Applications of Graphene- and

Biomolecule-Based Nanosensors and Nanodevices

Ke Xu,

Preeti Pratap, Mitra Dutta, and Michael Stroscio

Graphene-Based

DNA Sensors

Hatef

Sadeghi

Antimicrobial Perspectives for Graphene-Based

Nanomaterials

Archana

Ramchandra Deokar, Madhulika Sinha, Ganesh Gollavelli, and Yong-Chien

Ling

Biomedical Applications of Graphene

Maria Caffo, Lucia Merlo, Daniele

Marino, and Gerardo Caruso

Graphene

Biodevices

Xiaochen

Dong, Beibei Zhan, and Wei Huang

Antibacterial and Antifungal Activities

of Graphene Nanosheets

Montree

Sawangphruk

Applications of Graphene in Biosensing

D. P. Nikolelis, Z. H. Ibupoto, G.-P.

Nikoleli, and M. Willander

Graphene-Based

Biosensor Technologies

Arzum

Erdem, Ece Eksin, and Mihrican Muti

Graphene-Based

Laser Desorption/Ionization Mass Spectrometry for Bioanalytical

Applications

Suresh Kumar Kailasa, Hui-Fen Wu, and

Jigneshkumar V. Rohit

Richness of Graphene-Based Materials in

Biomimetic Applications

Bhaskar

Garg and Yong-Chien Ling

NANOCOMPOSITES

Graphene-Based

Polymer Nanocomposites

S. Chatterjee and B. T. T. Chu

Preparation of Cellulose/Graphene

Nanocomposites

Nguyen Dang Luong and Jukka Seppälä

Straightforward Routes for the

Preparation of Graphene-Based Polymer Nanocomposites

Giulio

Malucelli and Alberto Mariani

Polymer Devices with Graphene: Solar

Cells and Ultracapacitors

Agnieszka

Iwan, Bronislaw Szubzda, and Andrzej Sikora

ELECTRICAL/SENSOR DEVICES

Graphene-Based

Sensors: Current Status and Future Trends

Goutam

Koley, Amol Singh, and Ahsan Uddin

Effect of External Electric Fields on

the Multifunctional Applications of Graphene

Zhimin

Ao, Qing Jiang, Sean Li, Shixue Dou, and Guoxiu Wang

Impact of the Structural Properties of

Graphene on SiC Surfaces on Their Electronic Applications: An

Assessment

Jolanta

Borysiuk and Jakub Sołtys

Resistive Nonvolatile Memories Based on

Graphene-Related Materials: State of the Art

P. Bondavalli, D. Ihnatov, D. Pribat,

and P. Legagneux

Applications of Graphene-Based Materials

in Electronic Devices

Gaurav

Gupta, Minggang Zeng, Argo Nurbawono, Wen Huang, and Gengchiau Liang

Graphene-

and Graphene-Oxide-Based Gas Sensors

Vladimir Aroutiounian

NEW APPLICATIONS

Graphene-Based

Materials for Fuel Cells: Approaches and Applications

Junrui

Li and Haolin Tang

Chemistry and Applications of

Supramolecular Graphene Derivatives

Hugo Bares, Jean-Baptiste Verlhac, and

Dario M. Bassani

Applications of Graphene in Tissue

Engineering

Eoin

Murray, Brianna C. Thompson, and Gordon G. Wallace

Graphene

in Space

Domingo Aníbal García-Hernández and

Franco Cataldo

Graphene

Materials in Energy Storage Applications

Grzegorz

Lota, Krzysztof Fic, Ilona Acznik, and Katarzyna Lota

Applications of Graphene in

Fuel/Propellant Combustion

Bruce Chehroudi

Fabrication of Graphene-Based Porous

Materials and Their Applications in Environmental Fields

Zhu-Yin Sui, Ding Zhou, and Bao-Hang Han

New Energy Material: Graphene

Hongying

Hou, Xianxi Liu, and Jinhui Peng

Potential Applications of Graphene in

Polymer Electrolyte Membrane Fuel Cell

Avijit

Ghosh and Anil Verma

_______________________________________________

On Monday, March 21-23, 2016, Dr. Chehroudi has delivered a 3-day seminar on

Combustion and

Emission of Pollutants from Automotive Engines at the Society

of Automotive Engineers facility in Troy, Michigan. Thorough

and in-depth understanding of the thermodynamics, gas dynamics, and

combustion chemistry is at the heart of the intelligent approach towards

control of the engine combustion and emission of pollutants. To this

end, Dr. Chehroudi's seminar covers key aspects of the combustion of

the fuel air mixtures for best fuel economy at the lowest emission of

the harmful/regulated pollutants. from Automotive Engines at the Society

of Automotive Engineers facility in Troy, Michigan. Thorough

and in-depth understanding of the thermodynamics, gas dynamics, and

combustion chemistry is at the heart of the intelligent approach towards

control of the engine combustion and emission of pollutants. To this

end, Dr. Chehroudi's seminar covers key aspects of the combustion of

the fuel air mixtures for best fuel economy at the lowest emission of

the harmful/regulated pollutants.

Representatives from the following

organizations attended the seminar:

_ US Environmental Protection Agency

_ Honda R&D America Inc.

_ Mercedes Benz R&D North America

_ Southwest Research Institute

_ Toyota Technical Center USA, Inc.

_ Kohler Co

_ Mitsubishi Motors R&D of America Inc

_ General Motors

_______________________________________________

On March 3-9, 2016, Dr. Chehroudi was an

invited speaker by the Society of Automotive

Engineers, to conduct two seminars as listed below. The

seminars were held in the Le Royal Meridian Shanghai Hotel,

Shanghai, China.

First, "Ignition Issues and

Their Impacts on Performance, Efficiency and Emission of

Pollutants" in

Shanghai, China.

Second, "Gasoline Direct Injection"

engines

Updated version of the Ignition seminar was

presented to attendees from the following organizations:

_United Automotive Electronic Systems

Co. Ltd.

_GBI SOURCING LIMITED

_Blue Crown Technology (Suzhou) Co. Ltd.

_Chang An Ford (Chongqing)

_Shanghai Automotive Industry Company

_Chang An Ford Automotive Company, Ltd Power Train Branch

_Toyota

_Shell (Shanghai) Technology Limited

_SAIC

Engineers and researchers from the

following companies attended the Gasoline Direct Injection engine

seminar:

_ SAIC Motor Corporation Limited

(Passenger Vehicle Co.)

_ Changan Ford Automotive Co. Ltd

_ GBI Sourcing Limited

_ United Automotive Electronic Systems Co. Ltd (Joint Venture Bosch

& Zhong-Lian Automotive Electronics Co., Ltd)

_ Exxon Mobile

_ Shell (Shanghai) Technology Limited

_______________________________________________

On January 25 - 27, 2016, Dr.

Chehroudi was an invited speaker by the Society of Automotive

Engineers, to conduct a seminar on Gasoline Direct Injection in

Norwalk, California (Auto Partners Building, Cerritos College).

This is a highly updated version of the seminar introduced in 2010

which, in view of recent market share of GDI Engines, has become a very

popular professional seminar to attend amongst R&D/application engineers, researchers, technical

managers, regulators, and policy makers.

The objective of the

seminar is to present adequate information on combustion and

emission of pollutants for GDI engines in order to elevate

attendee's

background knowledge for an intelligent application and comfortable

understanding of the existing body of knowledge in direct injection

spark ignition engines. Below is the table of content for this

seminar:

●Mixture

Formation

●In-cylinder

flow characteristics and GDI combustion

●Fuel-air

mixing process

●Spray-wall

interactions

●Cold

start and wall wetting issues

●Combustion

Process and Control Strategies

●Engine

Operating Modes and Fuel Injection Strategies

●Early-injection,

late-injection, stoichiometric operation

●Operating

mode transition

●Split

Injection Strategy

●Two-stage,

split, and post injection

●Combustion

characteristics

●Homogeneous-charge

and stratified-charge combustion

●Effects

of Engine Operating and Design Parameters on GDI Combustion

●Injection

and ignition timings

●Spray

cone angle

●EGR

●Knock

resistance characteristics

●Air-assisted

versus single-fluid GDI fuel system

●Injector,

Combustion Chamber, and Intake Valve Deposits

●Emissions

of Pollutants - Reduction Approaches

●Hydrocarbon,

NOx and particulate

●Fuel

Economy

●Factors

affecting improved fuel economy

●Fuel

economy versus emissions compromise

●Select

Gasoline Direct-Injection Engines

●Benefits

of Turbocharging a GDI engine

During this visit, Dr.

Chehroudi had the pleasure of meeting

Ms. Jannet Malig, Director of the

Advanced Transportation

Technology and Energy Center (ATTE) at the Cerritos College.

During this meeting, avenues for future collaborations

have been explored on areas of mutual interest. This

is an exciting opportunity for the ATC to offer services towards

goals and objectives of the ATTE Center. ATC looks forward to

such future opportunities with ATTE Center.

_______________________________________________

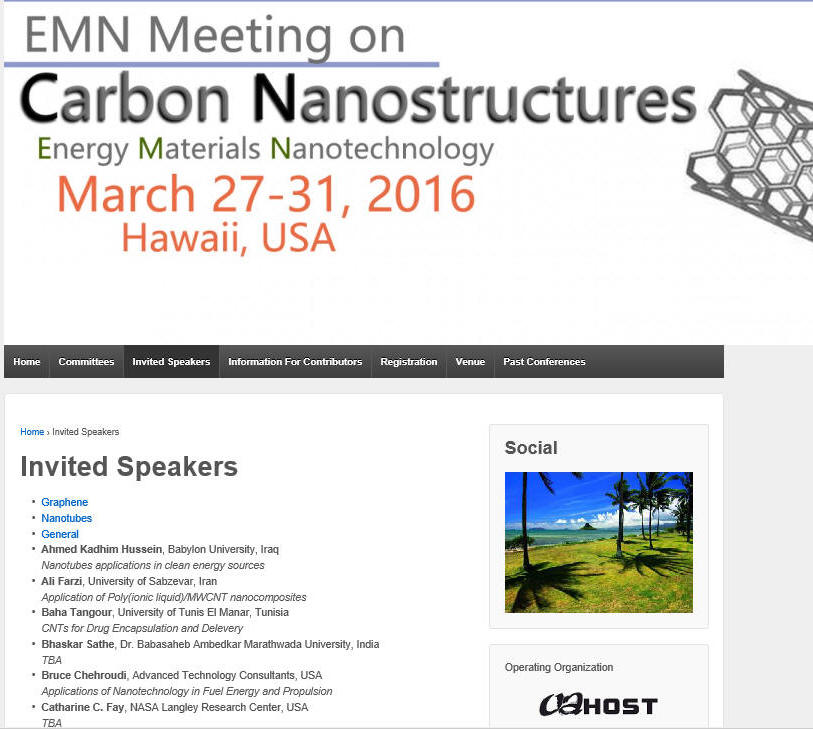

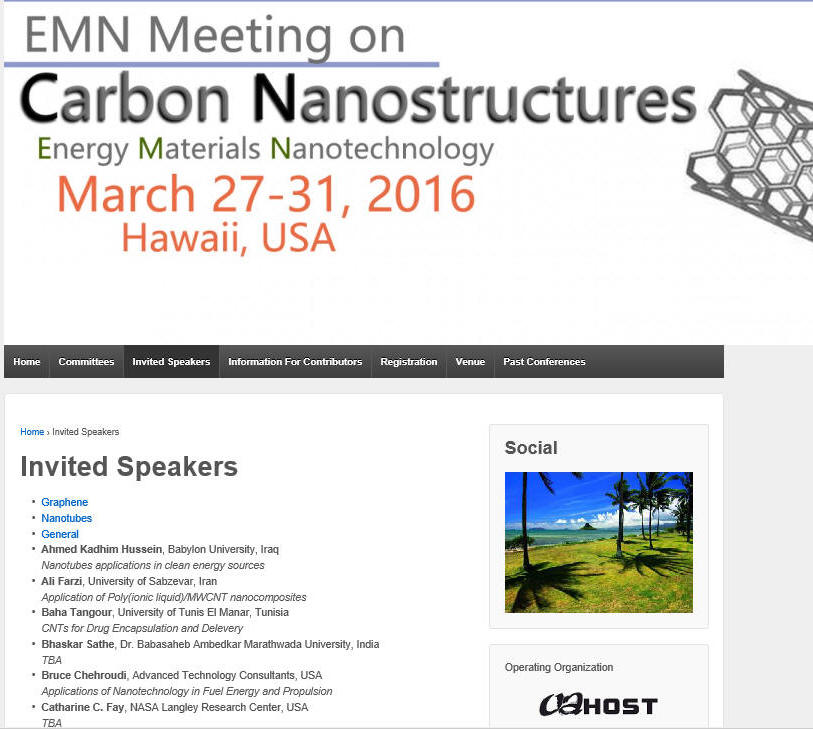

On March 27-31, 2016 Dr. Chehroudi

is an Invited Speaker to the

EMN Meeting on

Carbon Nanostructures, Energy

Materials Nanotechnology, Hawaii, USA. He will deliver a

talk titled "Applications of Nanotechnology in Fuel Energy and

Propulsion" The abstract of this work is presented below.

The modern advent of nano-

science/technology is usually marked with a lecture delivered by the

Noble laureate Richard Feynman in 1959 titled “There is Plenty of

Room at the Bottom”. Since then, there have been tremendous

progresses in a large number of directions using products

manufactured, and information learned, from nanoscale materials.

Nano-science is truly a multidisciplinary subject which has

penetrated into a large number of other areas/applications such as

medicine, pharmaceutical, dentistry, textile, sports, automotive,

computers, and energy, to name a few. In this presentation, a select

number of applications of knowledge learned at the nanosized range

are briefly discussed in the context of fossil fuel production and

propulsion. The aim is to demonstrate the great potential of

nanostructured materials in petroleum refining industry,

contributing towards efficient production of fuels and thereby of

different forms of energies. In particular, the catalytic role they

play is of paramount importance, especially considering that energy

producers are switching to ever-heavier fossil feedstocks (heavy

oil, tar sands, shale oil, and coal) while the supply of light

petroleum feedstock (high in hydrogen and low in sulfur and

nitrogen) is rapidly depleting. Applications of nanostructured

materials in naphtha reforming, hydrotreating (or

hydrodesulfurization), conversion of syngas (Water-gas shift and

Fisher-tropsch), and use of graphene/carbon-nanotubes in ignition,

combustion and propulsion are presented.

Click on the image to the right

for the

list of invited presentations and the titles of their research work.

Click

on

the image below for the details of the

Program & Abstracts and to download the file.

_______________________________________________

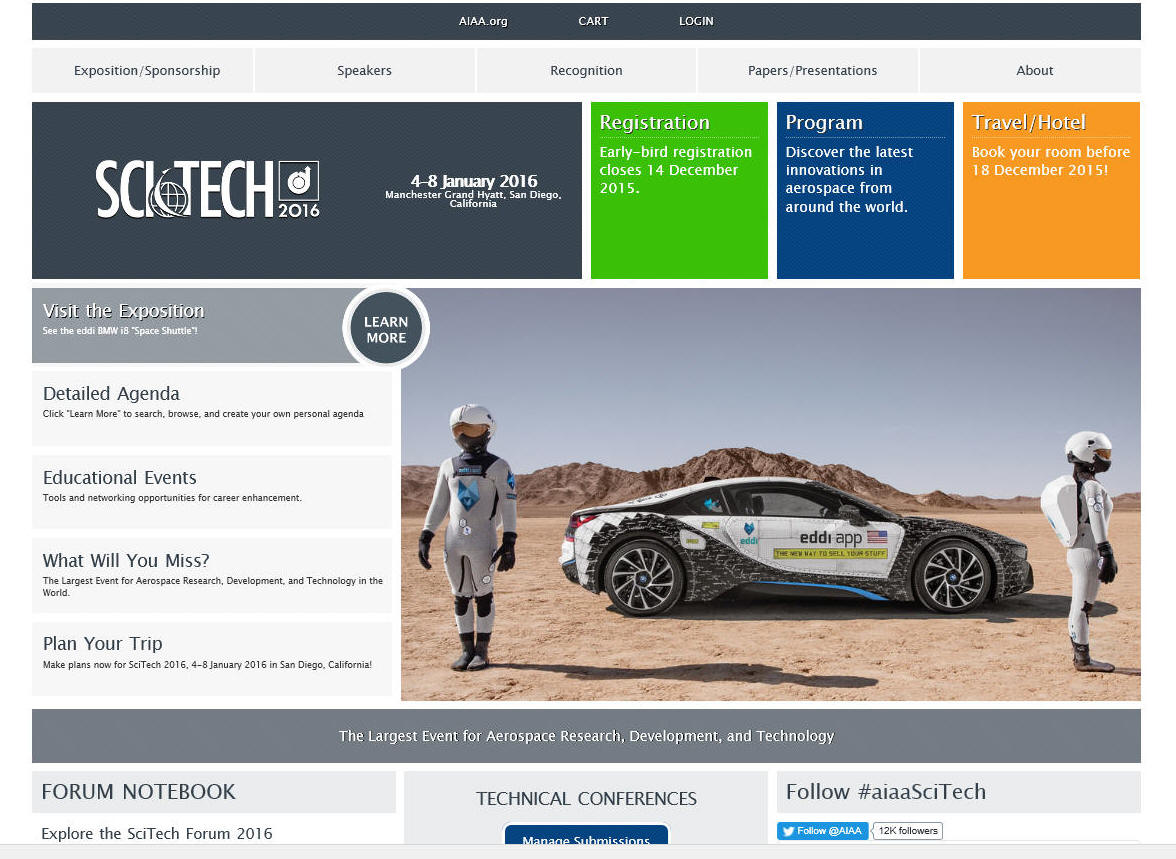

On January 4-8, 2016, Dr. Chehroudi

attended the

SciTech 2016, organized by the

American Institute of Aeronautics and

Astronautics (AIAA) to chair a session

(Friday, January 8, 2016, 9 am to 12:30 pm)

on

Rocket and Air Breathing Combustion II. The conference was held

in Manchester Grand

Hyatt Hotel, San Diego, California, USA.

Presentations will be made from the

following organizations:

United Technologies Aerospace Systems

University of Cincinnati

Air force Institute of Technology

Air Force Research Laboratory

Institute of Combustion Technology for aerospace Engineering

University of Stuttgart

Kassoy Innovative Science Solutions LLC

Central Connecticut State University

Paper Titles:

1. Effect of Nozzle Spacing on NOx

Emissions and Lean Operability- 2314538

2. Modeling Fuel Film Cooling on

Rocket Engine Walls _ 2317860

3. Numerical Simulations of a Single

Injector Gaseous Methane Rocket Combustion Chamber Abstract

4. Formulation of Equations to

Describe the Thermomechanical Response of a Gas to Transient,

Spatially Resolved Thermal Energy Addition-2320582

5. Performance Characterization of

the Busek BGT-X5 Monopropellant Thruster using AF-M315 and Other

Proprietary Blends-

6. Study of the Combustion of Beeswax

and Beeswax With Aluminum Powder in Hybrid Propellant Rocket Engine_

2311882 _

Also, as a senior member of the AIAA Propellant & Combustion

Technical Committee,

Dr. Chehroudi has attended the committee meeting on Monday, January

4, 2016 in which discussions were held on issues pertaining to

future technical directions and sessions in AIAA meetings, technical

publications, continuing education activities, best paper awards,

etc and decisions are made to move forward.

_______________________________________________

Dr Chehroudi has accepted a department Head position at the

Mechanical Engineering Department of the Arkansas Tech University to

temporarily help the department's progress into the future.

_______________________________________________

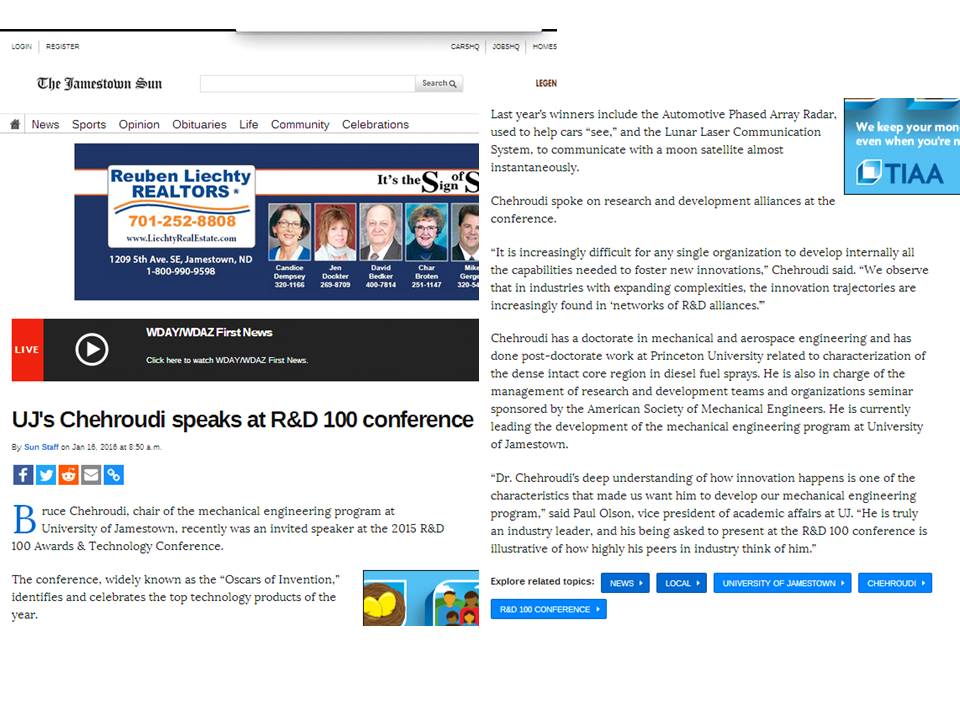

On November 12-13,

2015, Dr. Chehroudi was an

Invited Speaker

at the 2015 R&D

100 Awards & Technology Conference by the R&D 100 Magazine where the 100 most innovative

technologies introduced in the last year were personated. Dr.

Chehroudi delivered a presentation entitled "R&D

Alliances: Relational, Portfolio, and Network Factors Impacting

Outcomes".

For Conference Agenda

click on the "Agenda".

This is the first time

that educational conference is presented and it is held in

conjunction with the 53-year-old R&D 100 Awards program. These two

events - over a two-day period at Caesars Palace in Las Vegas -

highlights the great ideas and innovations in technology and science

unveiled by research and development teams in the past 15 months. It

is a celebration of great ideas and new promises - and a unique

opportunity to network with the leaders of the industries who are

making an impact in R&D today.

This conference

encompasses four separate tracks, which focus on areas of R&D that

reflect robust activity, creative innovation and practical

solutions. Presenters include leaders in their fields who will share

new developments, critical information and personal insights. The

tracks include presentations on R&D Strategies & Efficiencies,

Emerging Technologies & Materials, Innovation in Robotics &

Automation, and Instrumentation & Monitoring.

For more information, visit the

R&D 100 link at

http://www.rd100awards.com/speaker/481.

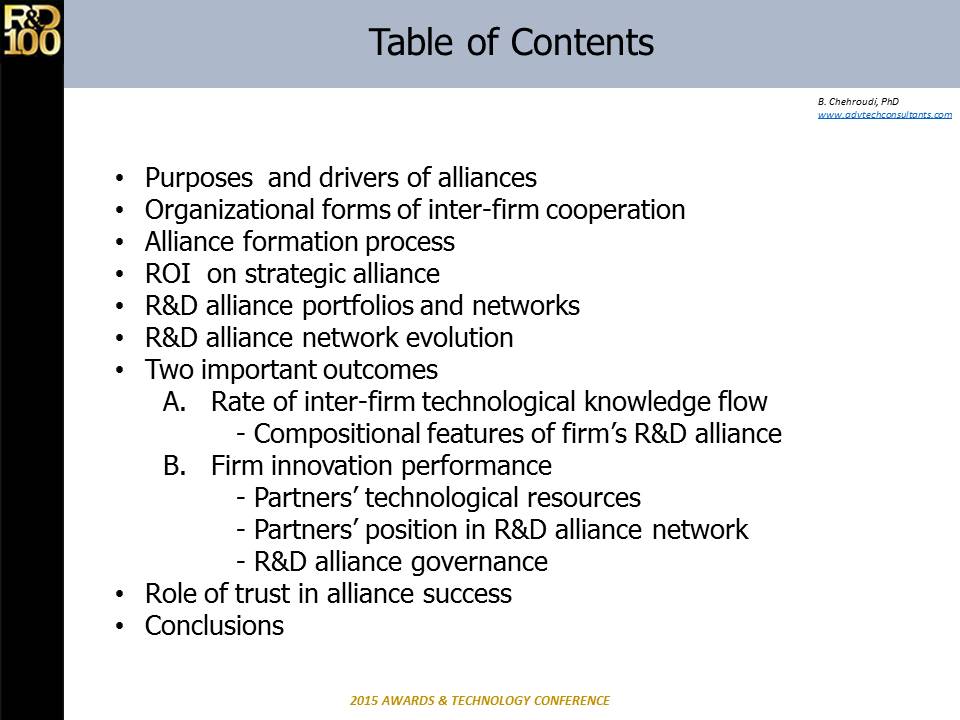

List

of topics covered:

_ Purposes

and drivers of R&D alliances

_ Organizational forma of inter-firm cooperation

_ ROI on strategic alliance

_ Alliance networks and portfolios

_ A pictorial example of alliance network evolution

_ Influence of compositional features of firms' R&D alliance

portfolios on rate of interfirm technological knowledge flow

_ Impact of partners' technological resources and position in R&D

alliance network on firm innovation

_ Effect of R&D alliance governance on firm innovation

_ Role of trust in alliance success

_ A template for efficient alliance formation/management

Abstract of Dr.

Chehroudi's

presentation:

It

is increasingly difficult for any single organization to develop

internally all the capabilities needed to foster new innovations.

Also, in early stages of knowledge development, knowledge tends to

be tacit (i.e., in-depth and highly inter-connected) and dense

(i.e., tightly packed and full of relationships). Hence, we observe

that in industries with expanding complexities, the innovation

trajectories are increasingly found in “networks of R&D alliances”.

Under such an environment, a firm’s success also depends on its

abilities to develop and manage collaborations (specifically, R&D

alliances) to create and apply new knowledge, products and

services. R&D alliances are viewed as channels for transfer of

technological knowledge related to the development of technological

innovations. It is shown that both technological knowledge flow and

factors of firm innovation depend on a number of R&D alliance

dimensions at the relational, portfolio, and network levels of

evaluation. Implications for R&D alliance managers in terms of

alliance partner selection and alliance architecture are presented

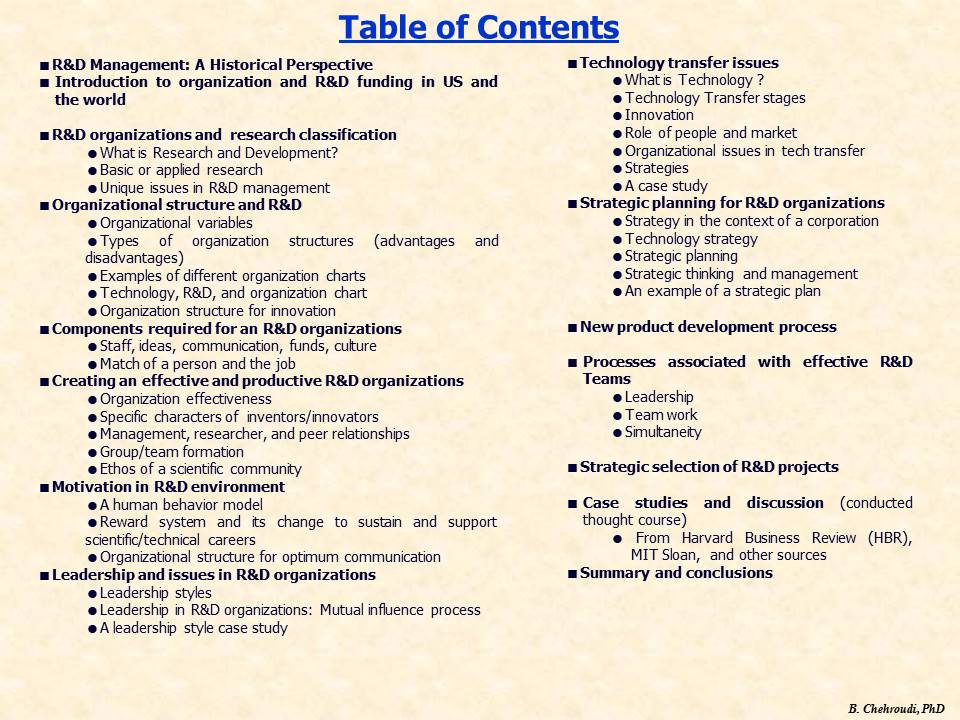

Click on the words "Table of

Contents" in the

right image to hear the

introduction to Dr. Chehroudi's

presentation at the 2015 R&D

100 Awards and Conference (high-speed internet access

is recommended):

INTRODUCTION.

Amongst many others, Dr.

Chehroudi has met

Mr. Dean Kamen

(see his detailed achievements at

Wikipedia).

They talked about future possible collaborations in areas of

R&D, innovation, entrepreneurship and other advanced technology related

areas. Dean Kamen is an inventor, entrepreneur, and advocate for

science and technology. He holds more than 440 U.S. and foreign

patents, many of them for innovative medical devices that have

expanded the frontiers of health care worldwide. Dean’s research has

led to a number of ground-breaking technology innovations, including

the Segway® Human

Transporter. In 1989, Kamen founded

FIRST (For Inspiration and Recognition of Science and

Technology), a program for students to get people interested in

science, technology, and engineering. One competition started and

run by

FIRST is the FRC or FIRST Robotics Competition. In 2011, it held

55 regional competitions around the globe, and one international

competition in St. Louis, MO.

FIRST has gained a great deal of publicity from companies as

well as many universities and colleges. His company

DEKA also

holds patents for the technology used in portable dialysis machines,

an insulin pump (based on the drug infusion pump technology),[10]

and an all-terrain electric wheelchair known as the iBOT, using many

of the same gyroscopic balancing technologies that later made their

way into the

Segway.